Laser Assisted Vacuum ESC Supersonic Deposition Spray Gun

A laser-assisted, supersonic technology, applied in spray booths, spray devices, liquid spray devices, etc., can solve the problems of not being able to adapt to the spraying process, and achieve the effects of improving the scope of application, reducing volume, and enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

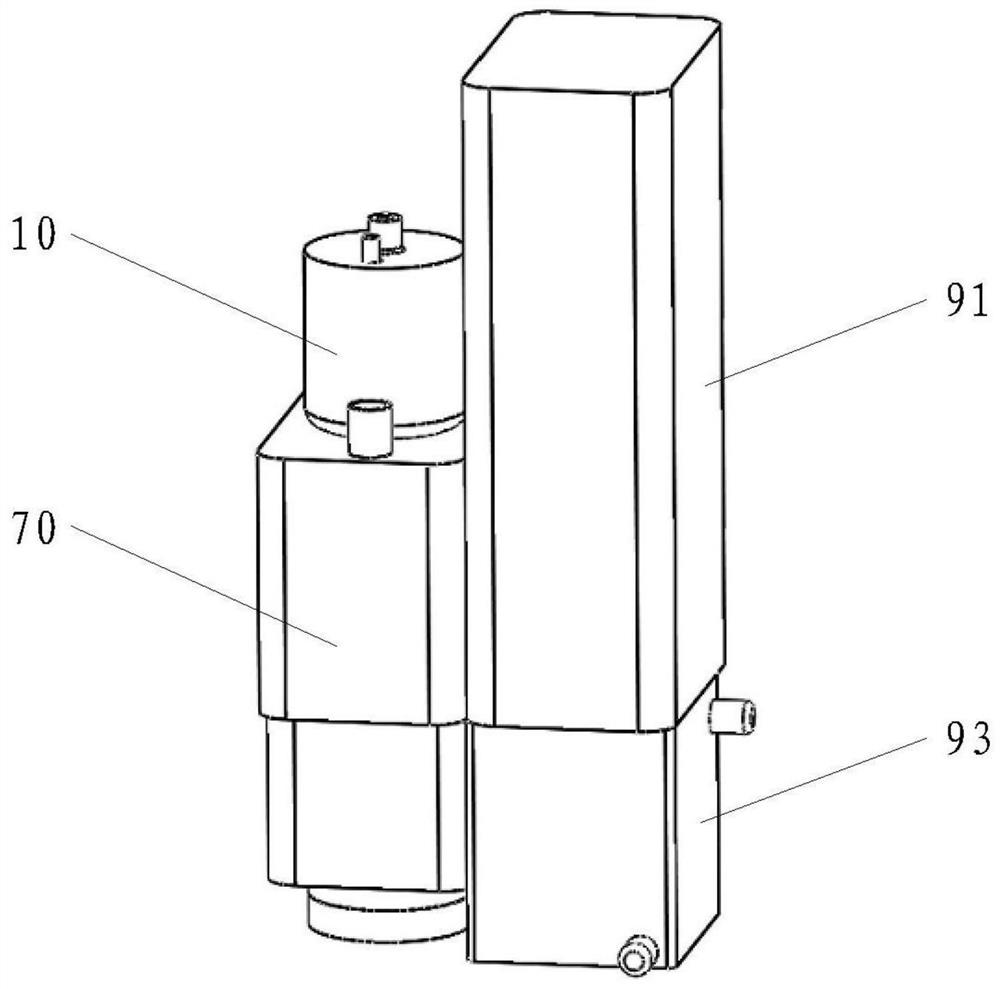

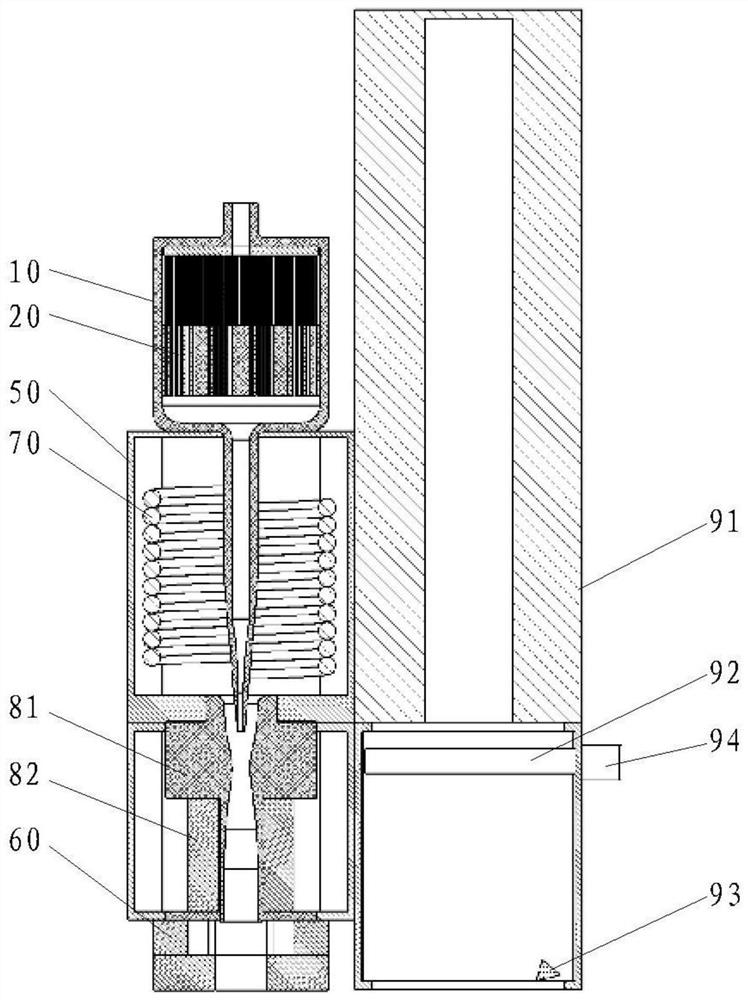

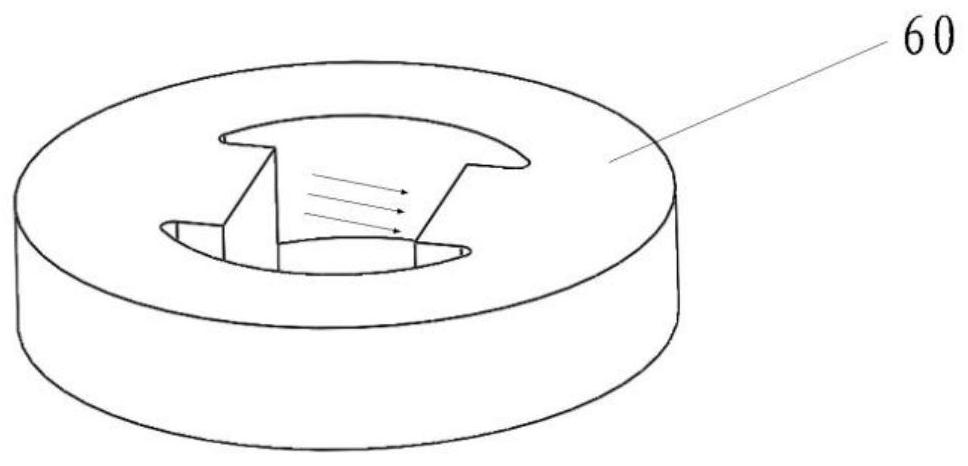

[0024] As shown in the figure, the laser-assisted vacuum electric sweep supersonic deposition spray gun in this embodiment includes a cold spray head, a laser generator 91 and a laser beam control device, and the laser beam control device is installed at the exit of the laser generator for The emission direction of the laser beam is controlled so that the laser beam and the injection direction of the cold nozzle converge at one point. combine figure 1 with figure 2 As shown, the cold spray head is used to achieve cold spraying, so that the powder is accelerated and hits the substrate in a completely solid state, and a large plastic deformation occurs to deposit on the surface of the substrate to form a coating; the laser generator can be a laser or a laser for introducing laser Introducing the optical path, the laser generator is an existing device that can be used to emit a laser beam. Specifically, when the electrons in the atom absorb energy and jump from a low energy lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com