Stirring device for production of cosmetics

A stirring device and cosmetics technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as inability to achieve uniform dispersion and insufficient mixing of cosmetic raw materials, so as to avoid deterioration of cosmetics and save The effect of production cost and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

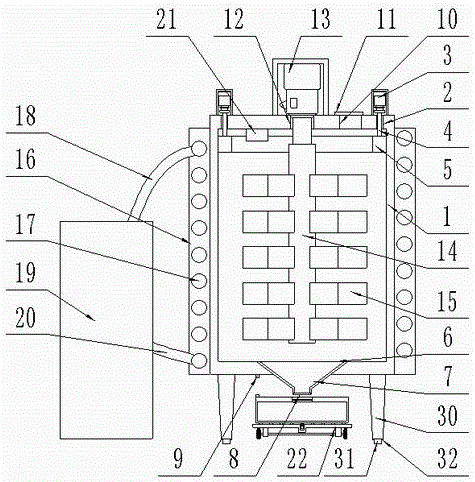

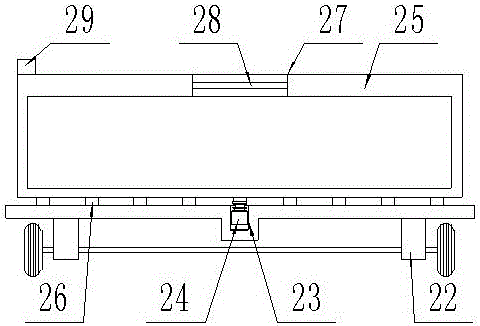

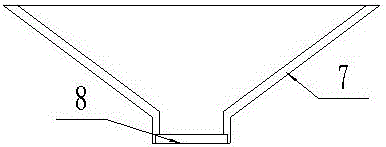

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, a stirring device for cosmetic production includes a stirring box 1, a stirring device and a wall scraping device are arranged on the stirring box 1, a heat preservation device is provided on the outer surface of the stirring box 1, and an outer surface of the stirring box 1 An automatic feeding device is provided below, and the wall scraping device is composed of a plurality of circular holes 2 equidistantly opened on the upper surface of the mixing box 1 along the circumferential direction, and a servo telescopic motor arranged on the upper surface of the mixing box 1 and located at the circular holes 2 13. The driving rod 4 arranged at the telescopic end of the servo telescopic motor 3 and inserted into the round hole 2, and the scraper ring 5 arranged on the inner surface of the mixing box 1 and connected to one end of the driving rod 4 on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com