Non-penetrating filtration surgery

a filtration surgery and laser ablation technology, applied in laser surgery, medical science, surgery, etc., can solve the problems of not being fine enough for some patients and/or protocols, preventing the practical use of low-depth laser ablation, and thermal damage to the membrane and/or other eye tissue does not heal as readily, so as to reduce or eliminate the scanning of the laser. , the effect of reducing the degree of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

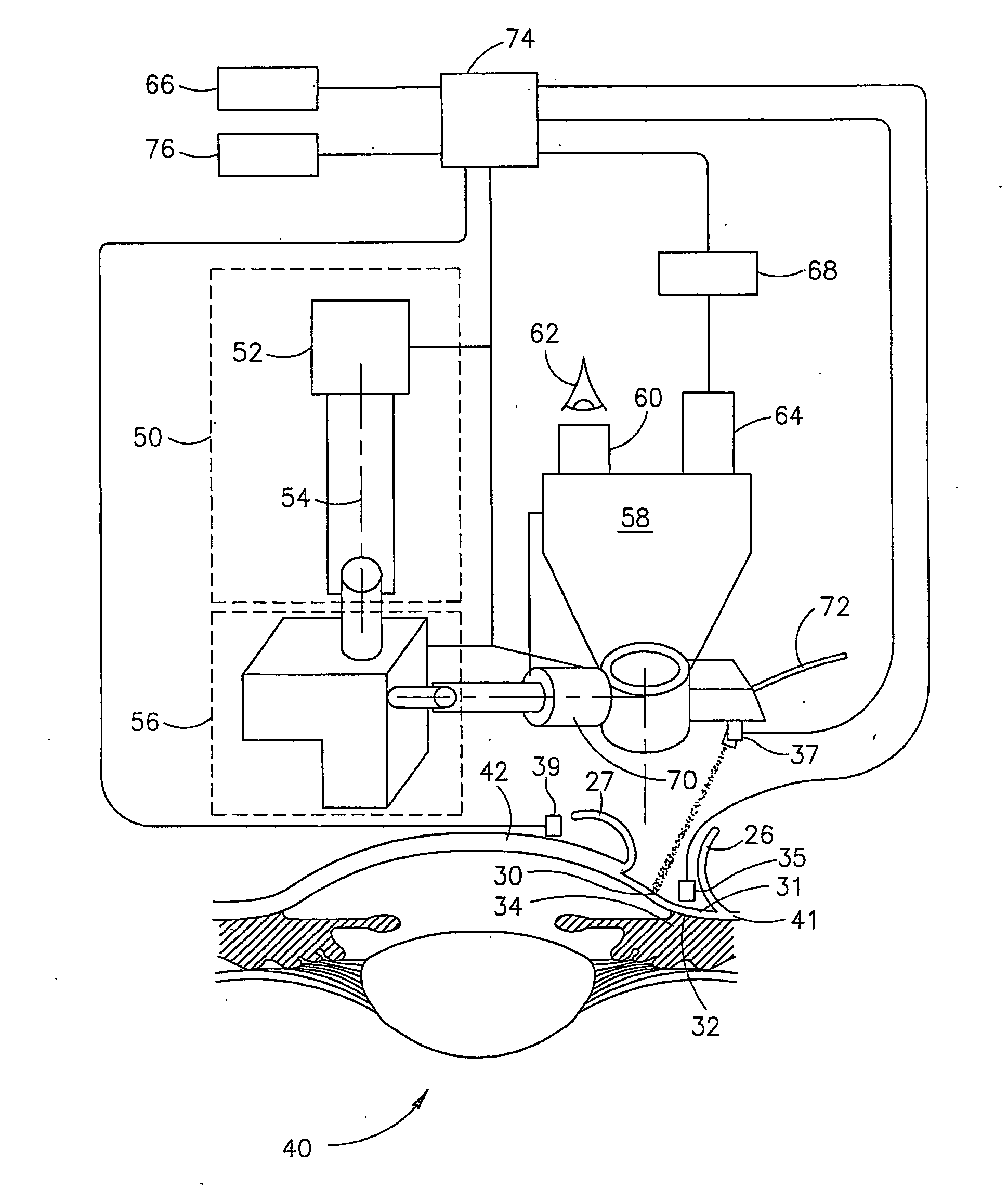

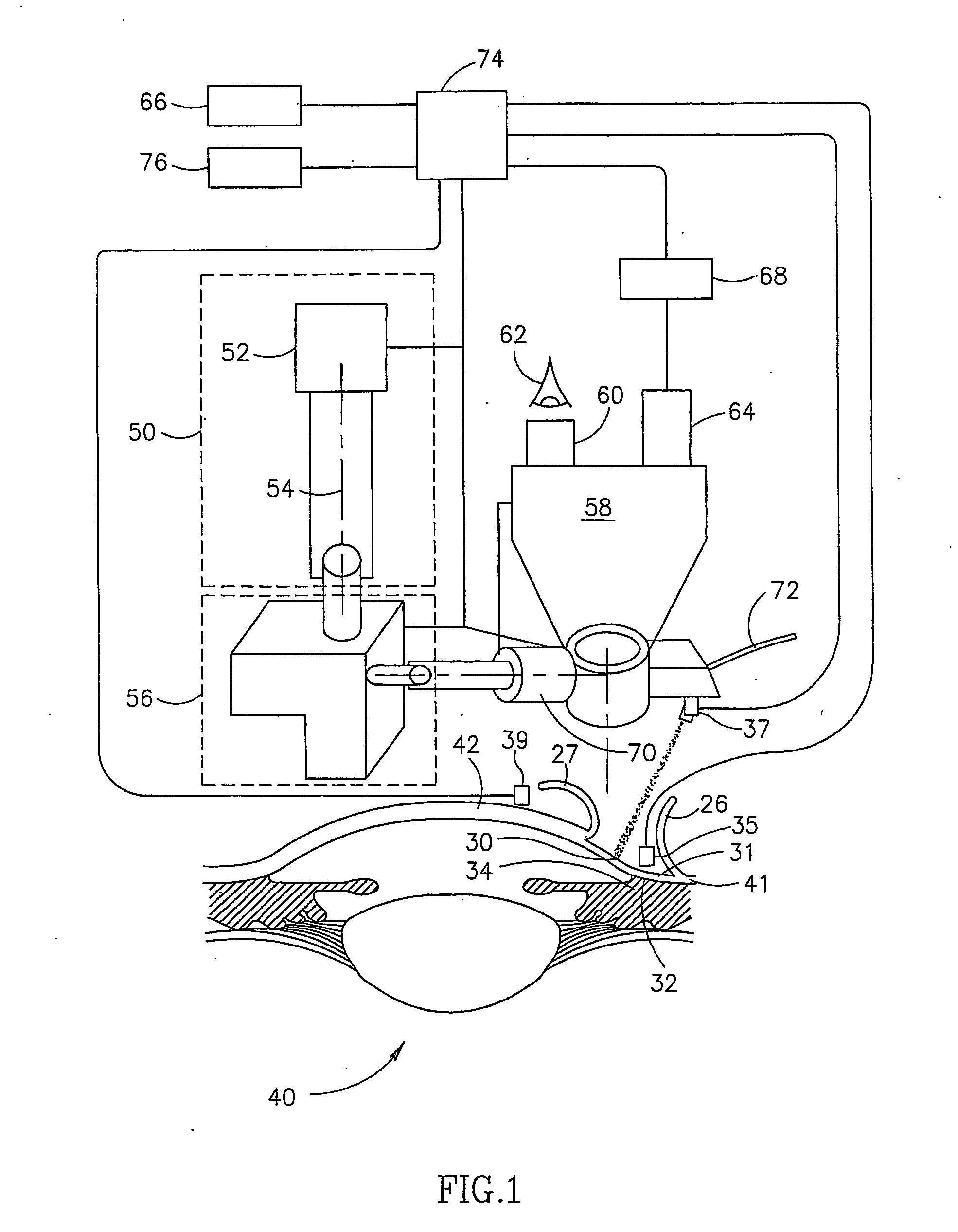

[0058]FIG. 1 is a schematic illustration of an exemplary ophthalmologic ablation system 50, during a non-penetrating filtration procedure in accordance with an exemplary embodiment of the invention.

[0059] Referring first to an eye 40, an exemplary filtration procedure using system 50 comprises ablating parts of an area 31 of a sclera 41 and / or a cornea 42 in an area 30. Some of the ablation is directed to those areas overlying a Schlemm's canal 34 and / or trabecular meshwork 32. The size of area 30 is exaggerated in FIG. 1, as in many procedures, area 30 is significantly smaller than area 31 and may comprise substantially only the boundary area between cornea 42 and sclera 41 that overlies the Schlemm's canal. In some procedures, however, a larger portion of the cornea may be ablated. Optionally, a scanner is used to scan a laser spot over an area of the sclera larger than the spot. A more detailed description of an exemplary filtration procedure and an exemplary scanner is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com