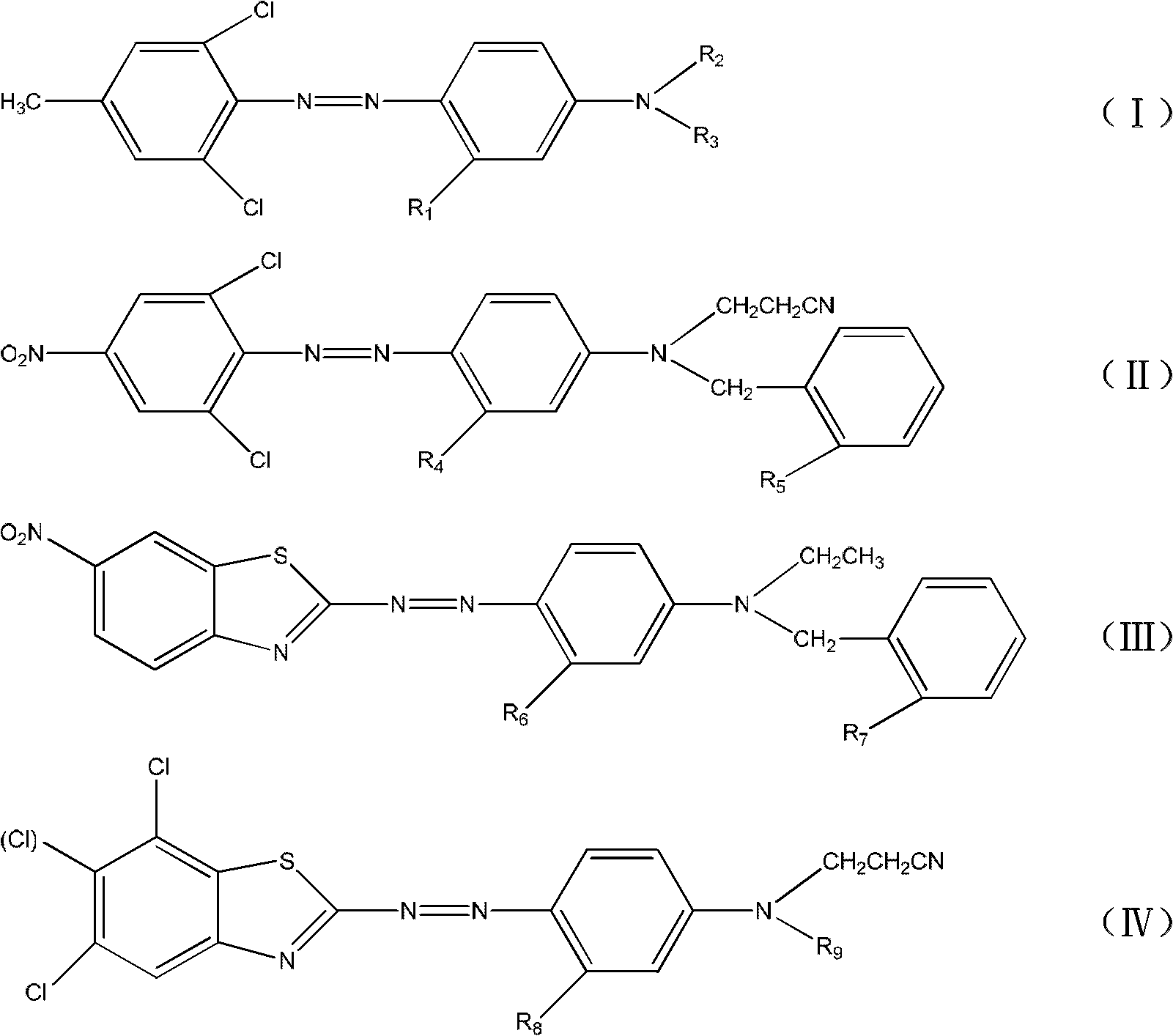

Oxidation-resistant disperse dye composition and preparation and application thereof

A technology of disperse dyes and oxidation resistance, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of reducing production efficiency, polluting the environment, and disperse dyes are not resistant to strong oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

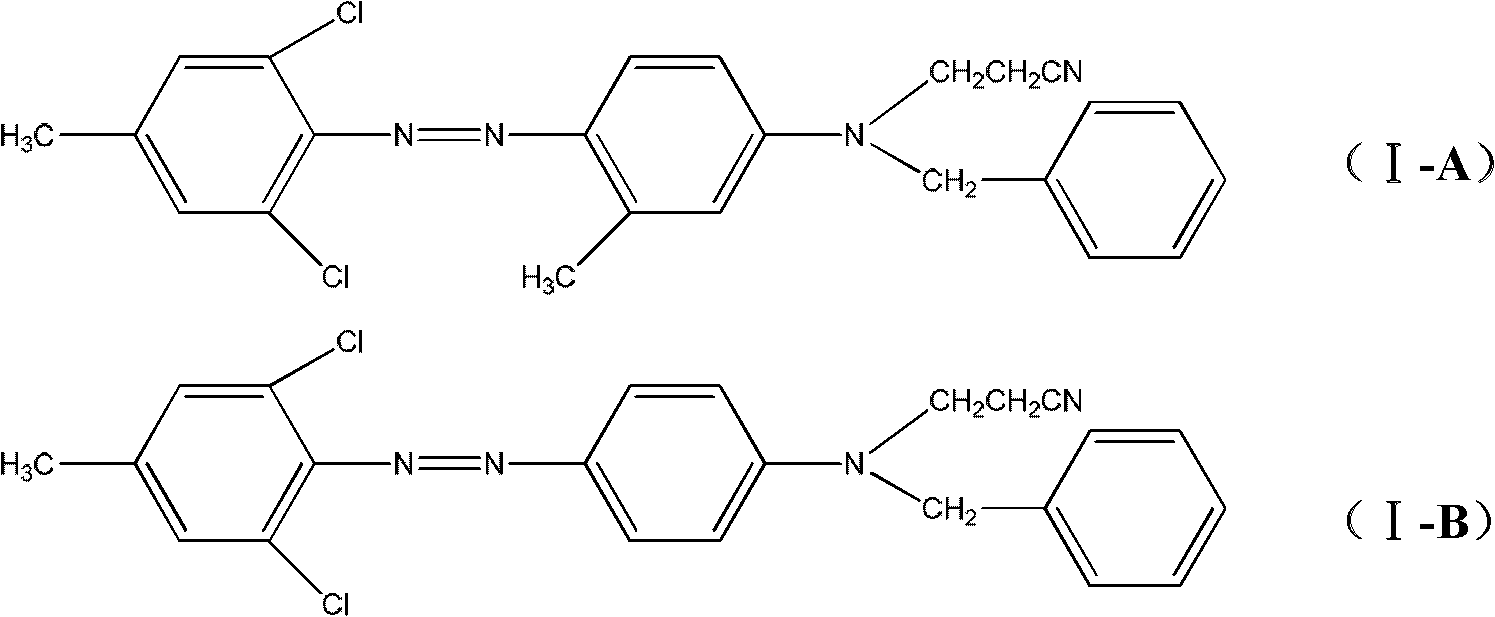

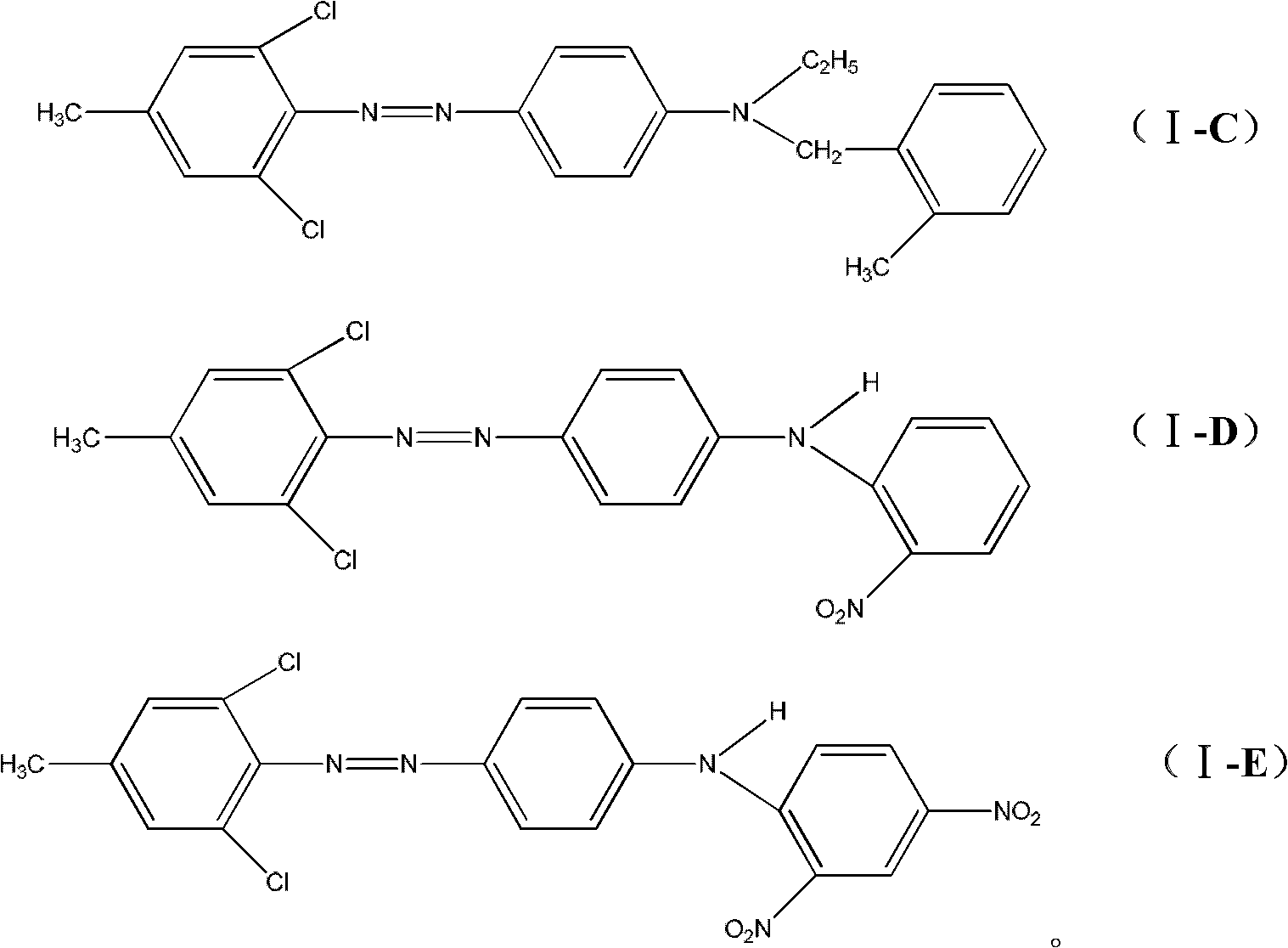

Method used

Image

Examples

Embodiment 1

[0060] Mix 100 kg of the original disperse dye shown in formula (II-B) and 98 kg of formula (II-C), and 250 kg of dispersant MF with water, grind and disperse with a grinder, and spray dry to obtain the finished product. The dye is suitable for one-bath one-step dyeing of polyester fabric pretreatment and dyeing, and can provide orange hues with excellent fastness properties for fabrics.

Embodiment 2

[0062] Mix 100 kg of the original disperse dye shown in formula (III-A), 60 kg of formula (I-C), and 450 kg of modified dispersant MF with water, grind and disperse with a grinder, and spray dry to obtain the finished product. The dye is suitable for one-bath and one-step dyeing of polyester fabric combined with pretreatment and dyeing, and can provide a blue hue with excellent fastness properties to the fabric.

Embodiment 3

[0064] One-bath one-step method for pre-treatment and dyeing of polyester fabrics.

[0065] In the intermittent dyeing machine, put 250KG of polyester knitted fabric, add 2500 liters of dyeing water according to the bath ratio of 1:10, add 10.00KG sodium percarbonate, 1.50KG caustic soda, modified dispersant MF 6KG, embodiment 1 The medium disperse dye composition is 10KG, the pH value is 13, the dyeing treatment temperature is 120-122° C., and the dyeing time is 60 minutes. After the cloth is dried, a bright orange fabric is obtained. The fabric surface is clean, the color is uniform, and the handle is smooth and soft. Fastness test results are shown in Table 1:

[0066] Table 1

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com