Nickel coated copper powder and process for producing the same

A technology of nickel-plated copper and copper particles, applied in liquid chemical plating, conductive materials, conductive materials dispersed in non-conductive inorganic materials, etc. To achieve the effect of improving adhesion and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

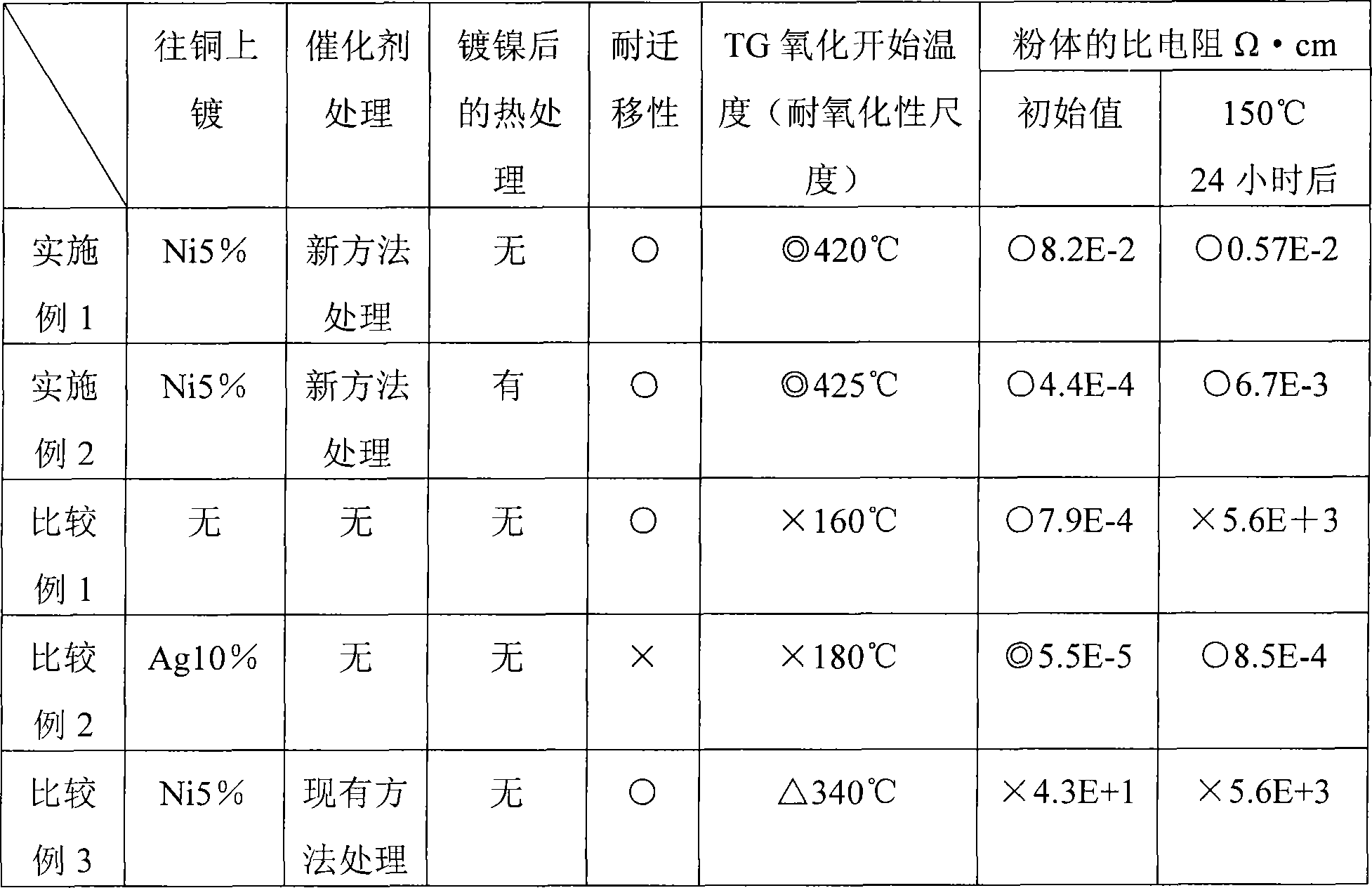

Embodiment 1

[0034] (1) Add 1kg of copper powder (D to 5L of pure water at 50°C) 50 = 5.2 μm), stir to prepare copper powder slurry.

[0035] (2) Next, 100 ml of Meltek Activator 352 manufactured by Meltek Corporation was added to the copper powder slurry, and the mixture was stirred for 10 minutes.

[0036] (3) Then, 100 ml of hydrazine hydrate was added to precipitate palladium on the surface of the copper particles.

[0037] (4) After standing, 4 L of the supernatant was removed.

[0038] (5) 4 L of pure water was added to the slurry, and after reaching 50° C., a nickel plating solution (an electroless nickel plating solution obtained by adding 1.2 L of Ni-426B to 1.2 L of Ni-426A manufactured by Meltech Corporation) was added to prepare Nickel-plated copper powder in which palladium is adhered to copper particles.

[0039] (6) Then, the nickel-plated copper powder according to Example 1 was obtained by filtering, washing, and drying in accordance with the usual method.

Embodiment 2

[0041] Since the production method of the nickel-plated copper powder is the same as that of the above-mentioned Example 1, the description thereof is omitted. However, after the above (6), heat treatment was performed at 300° C. for 1 hour in a 1% hydrogen-99% nitrogen atmosphere without deteriorating the powder dispersibility. The purpose of the heat treatment is to align the crystallinity of the nickel by heat-treating the nickel part. Thus, the nickel-plated copper powder according to Example 2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com