Surface treating agent for tin or tin alloy material

A surface treatment agent and surface treatment technology, applied in the field of pin structure, can solve the problems of insufficient heat resistance, low repeatability, increase product cost, etc., so as to inhibit the decrease of flux wettability, prevent transformation or oxidation , the effect of excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

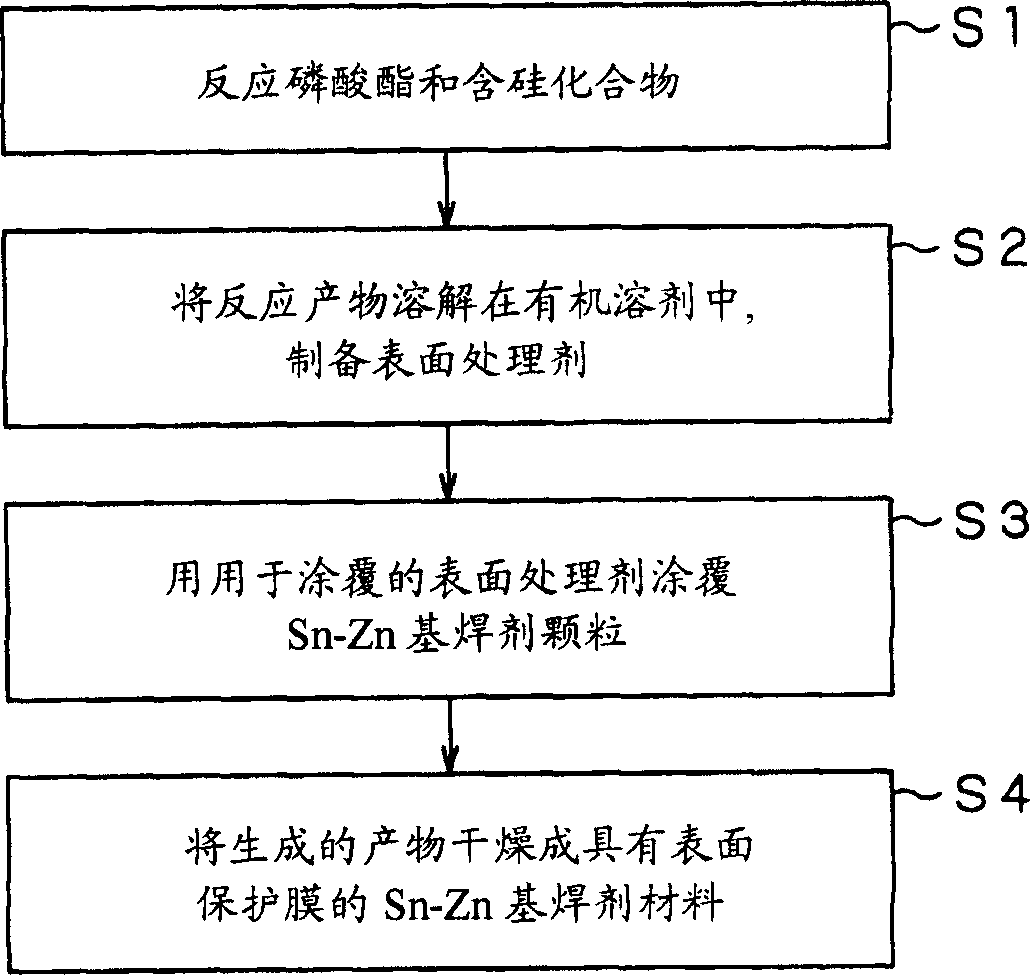

[0106] Example 1 shows an example of the reaction of a phosphate ester and a silicon-containing compound.

[0107] 47.3 g (1 mol) of oleyl phosphate (which is a mixture of oleyl acid phosphate with a single OH group and oleyl acid phosphate with two OH groups, manufactured by JOHOKU KAGAKUKOGYO under the trade name JP-518-O, the OH group concentration is 1.5OH group / mole) and 10.4 g (0.5 mol) of tetraethoxysilane (manufactured by KANTOH KAGAKU) were put into a 100 ml eggplant-shaped flask, and heated at 80°C using a magnetic stirrer. Stir at reflux for 1 hour. use 31 P-NMR and 29 The reaction mass was analyzed by Si-NMR. It was found that P-O-Si bonding has been formed, as Figure 7A and 7B shown.

Embodiment 2

[0109] Example 2 shows that the reaction product of a phosphate ester and a silicon-containing compound has improved heat resistance compared to the phosphate ester itself used as a starting material.

[0110] In an Ar atmosphere, T-DTA analysis was performed on the synthesized product (tetraethoxysilane-modified oleyl phosphate) and oleyl phosphate in Example 1 at a heating rate of 20° C. / min. It was found that the decomposition initiation temperature of the former was 278°C and that of the latter was 259°C. This shows that the heat resistance is improved by about 20° C. in terms of the decomposition initiation temperature.

Embodiment 3

[0112] Example 3 shows that the reaction product of a phosphate ester and a silicon-containing compound has improved heat resistance compared to a coating in which the phosphate ester itself was used as a raw material.

[0113] A 10 wt% solution of the synthetic product of Example 1 (tetraethoxysilane-modified oleyl phosphate) and a 10 wt% solution of oleyl phosphate were prepared in isopropanol, respectively. These solutions were respectively applied to sufficiently degreased zinc plated stainless steel plates (zinc plated by SHIN-NITTETSU, non-chromic acid product, 60 mm × 80 mm × 0.6 mm) to form a film on it. Each coating film was about 1 μm.

[0114] Each of these surface-processed zinc-plated stainless steel sheets was left to stand for 30 minutes in a desiccator maintained at a temperature of 150°C. Meanwhile, the temperature of 150° C. is a preheating temperature used in reflow soldering. Before and after heat treatment, FT-IR analysis was performed on the coated fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com