Surge-withstanding insulating paint with flexibility and attrition resistance

A wear-resistant and flexible technology, used in polyester coatings, polyether coatings, polyamide coatings, etc., can solve the problems of brittleness of enameled wire insulation film and incomplete resin bridging, and achieve superior strength, The effect of excellent wear resistance and excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

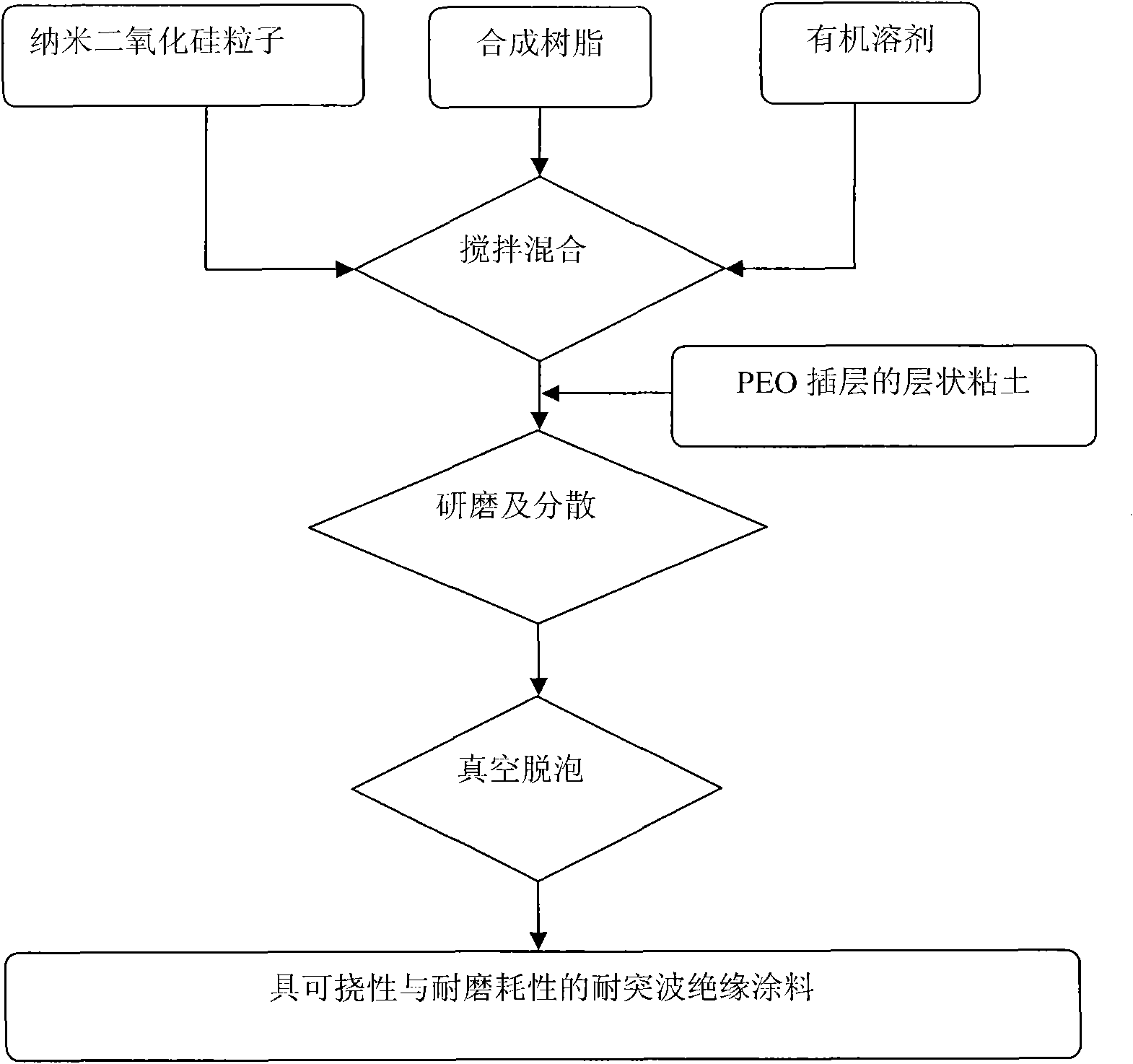

Method used

Image

Examples

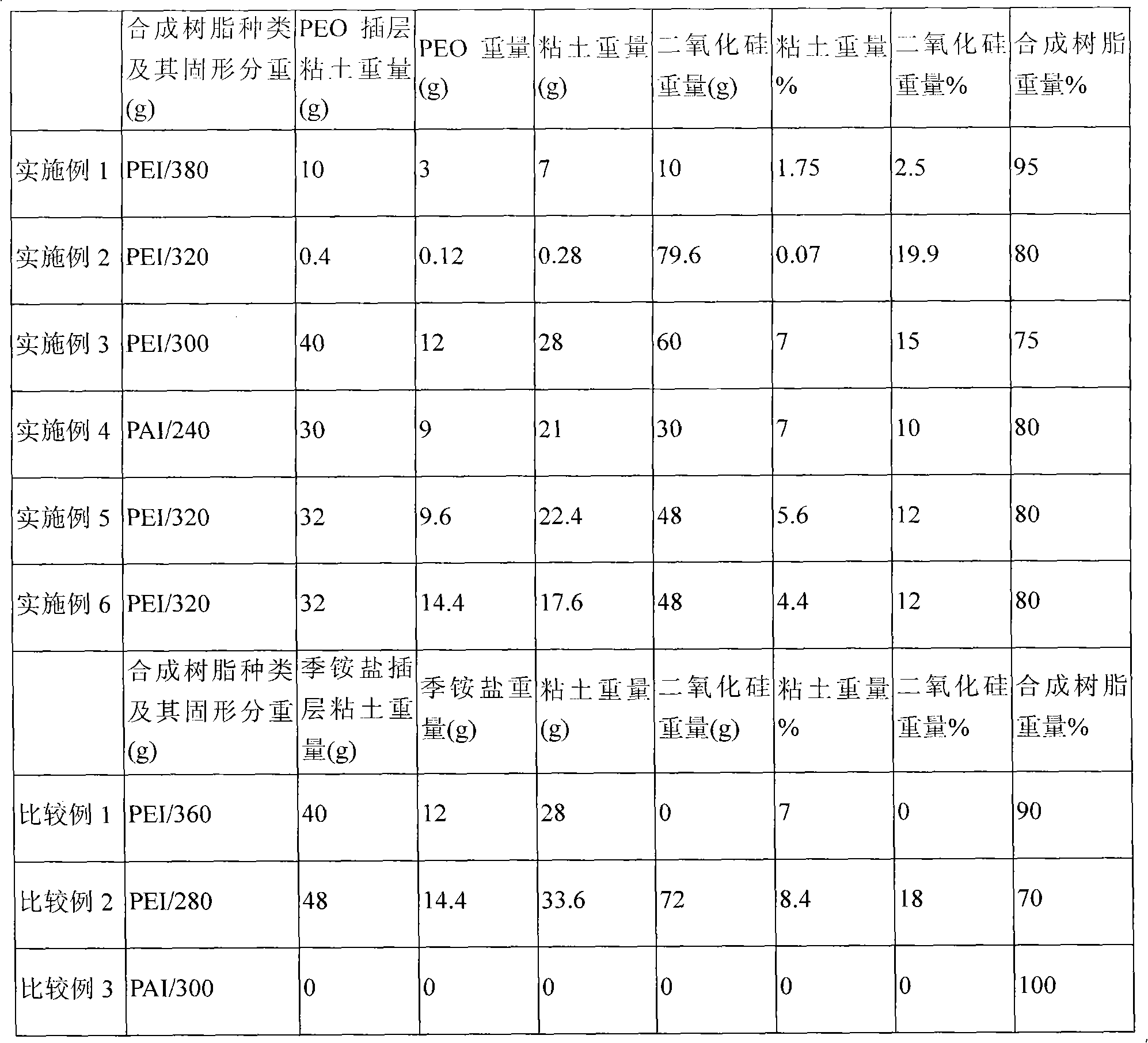

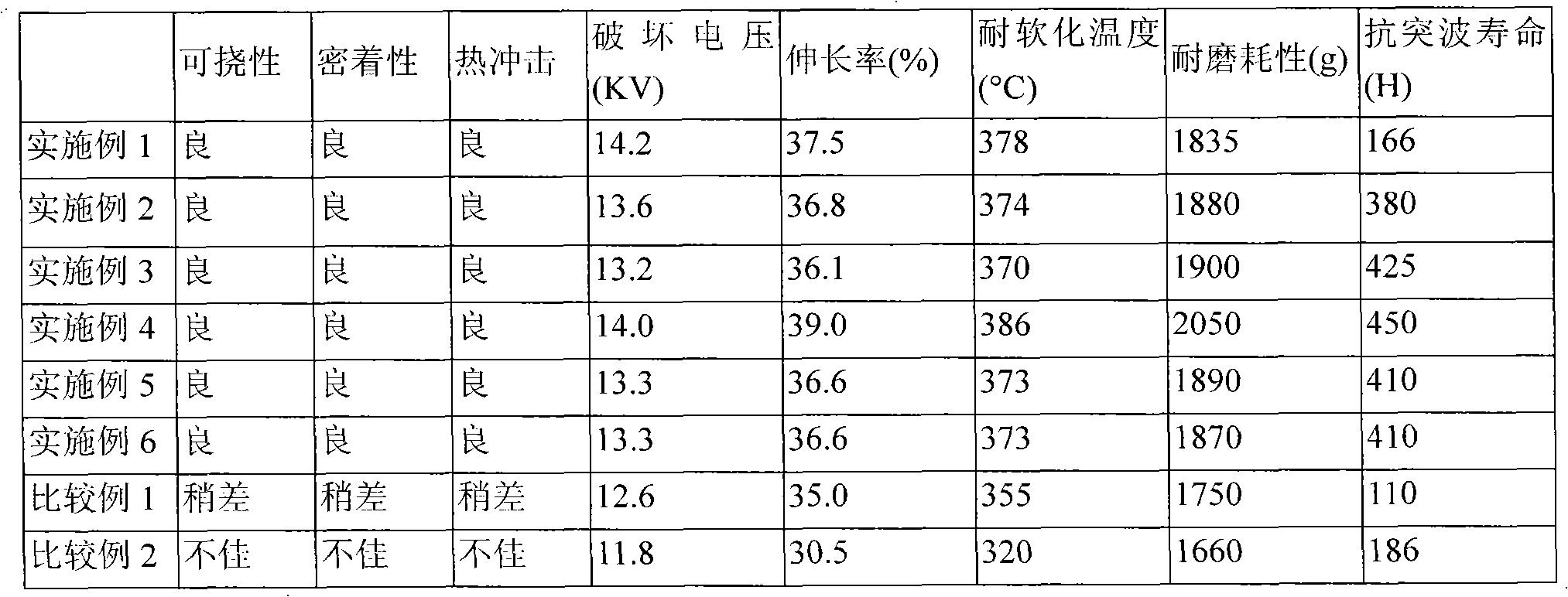

Embodiment 1

[0028] Example 1: use a 1000mL beaker, add 950g synthetic resin PEI solution (solid content: 40%, 470g solvent Cresol, 70g solvent NMP, 30g solvent xylene) and 10.0g nano-silica particles, stir at room temperature for 30 minutes at high speed, Then add 10.0g of PEO-intercalated Laponite RDS clay (PEO molecular weight 100,000, PEO and clay weight ratio is 30:70), after grinding and dispersing, vacuum defoaming for 30 minutes to obtain a flexible and wear-resistant Frequency conversion surge insulating resin coating.

Embodiment 2

[0029] Example 2: use a 1000mL beaker, add 800g synthetic resin PEI solution (solid content: 40%, 380g solvent cresol, 70g solvent NMP, 30g solvent xylene) and 79.6g nano-silica particles, and stir at high speed for 30 minutes at room temperature , and then add 0.4g of PEO-intercalated Laponite RDS clay (PEO molecular weight 100,000, PEO:clay weight ratio 30:70), after grinding and dispersing, vacuum defoaming for 30 minutes to obtain a flexible and wear-resistant Frequency conversion surge resistant insulating resin coating.

Embodiment 3

[0030] Example 3: use a 1000mL beaker, add 750g synthetic resin PEI solution (solid content: 40%, 350g solvent cresol, 70g solvent NMP, 30g solvent xylene) and 60.0g nano-silica particles, stir at room temperature for 30 minutes , and then add 40.0g of PEO-intercalated Laponite RDS clay (PEO molecular weight is 100,000, PEO to clay weight ratio is 30:70), after grinding and dispersing, vacuum defoaming for 30 minutes to obtain a flexible and wear-resistant Anti-frequency surge insulation resin coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com