Water-based capillary crystalline type waterproof material with controllable reaction speed as well as preparation method and application of waterproof material

A technology of osmotic crystallization and reaction speed, applied in the field of waterproof materials for construction, to achieve the effect of lowering the freezing point, good impermeability, and easy penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

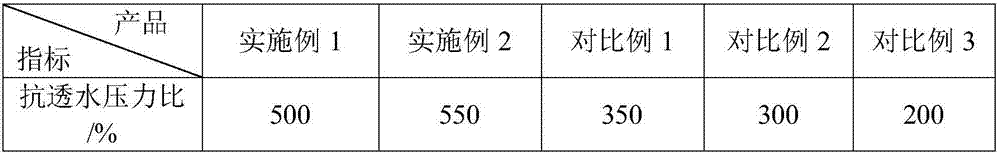

Examples

Embodiment 1

[0039] Party:

[0040] 35 parts of sodium silicate, 0.07 part of sodium dodecylsulfonate as a surfactant, 0.1 part of sodium borate as a reaction delay agent, 0.12 part of thiourea as a reducing agent, 3.0 parts of triethanolamine as a reaction accelerator, and 3.0 parts of triethanolamine as a reaction accelerator, and 0.1 part of sodium borate as a reaction delay agent. 0.07 parts of potassium carbonate, 0.15 parts of sodium hexametaphosphate as a metal ion blocking agent, 0.4 parts of magnesium hexafluorosilicate as a surface strengthening agent, 0.3 parts of silver diammine hydroxide as a rust inhibitor, and 60.79 parts of deionized water.

[0041] Preparation:

[0042] (1) Weigh each component according to the proportion of the formula, then add deionized water into the reactor, and then add surfactant, reaction delay agent, reducing agent, reaction accelerator, antifreeze agent, metal ion blocker, Add surface enhancer and antirust agent to water successively and stir fo...

Embodiment 2

[0045] Party:

[0046] The sodium silicate is 37 parts, the surfactant is 0.1 part of sodium dodecylbenzenesulfonate, the reaction delay agent is 0.3 part of tetrasodium edetate, the reducing agent is 0.17 part of sodium thiosulfate, and the reaction accelerator is 4.5 parts of triethanolamine, 0.09 parts of sodium carbonate as an antifreeze agent, 0.25 parts of magnesium metaphosphate as a metal ion blocking agent, 0.6 parts of magnesium hexafluorosilicate as a surface strengthening agent, 0.2 parts of sodium nitrite as a rust inhibitor, and 0.2 parts of deionized water 56.79 servings.

[0047] Preparation:

[0048] (1) Weigh each component according to the proportion of the formula, then add deionized water into the reactor, and then add surfactant, reaction delay agent, reducing agent, reaction accelerator, antifreeze agent, metal ion blocker, Add surface enhancer and antirust agent to water successively and stir for 40 minutes to obtain a mixed solution;

[0049] (2) Co...

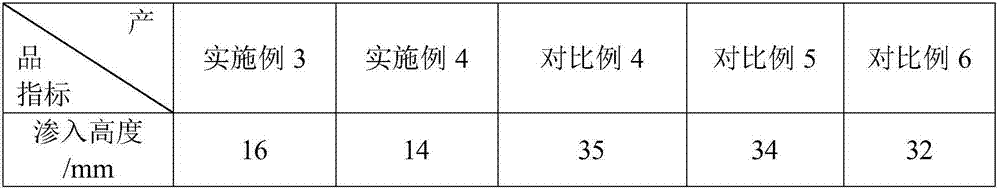

Embodiment 3

[0051] Party:

[0052] 36 parts of sodium silicate, 0.13 part of sodium dodecylsulfonate as surfactant, 0.7 part of sodium borate as reaction delay agent, 0.18 part of sodium thiosulfate as reducing agent, 0.5 part of triethanolamine as reaction accelerator, antifreeze The agent is 0.10 parts of potassium carbonate, the metal ion blocking agent is 0.20 parts of magnesium metaphosphate, the surface strengthening agent is 0.5 parts of sodium fluorosilicate, the antirust agent is 0.4 parts of silver diammine hydroxide, and 61.29 parts of deionized water.

[0053] Preparation:

[0054] (1) Weigh each component according to the proportion of the formula, then add deionized water into the reactor, and then add surfactant, reaction delay agent, reducing agent, reaction accelerator, antifreeze agent, metal ion blocker, Surface enhancer and antirust agent were successively added to water and stirred for 45 minutes to obtain a mixed solution;

[0055] (2) Continue to add the aqueous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com