Grouting material for balcony or roof waterproof layer reconstruction construction method and preparation method and application of grouting material

A technology of grouting material and waterproof layer, which is applied to roof covering layer, roof using sealing aggregate, roofing, etc. It can solve the problems of low solid content, easy cracking, and inability to adapt to the deformation of the base layer, and achieves simple preparation and excellent penetration. Strong, good pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

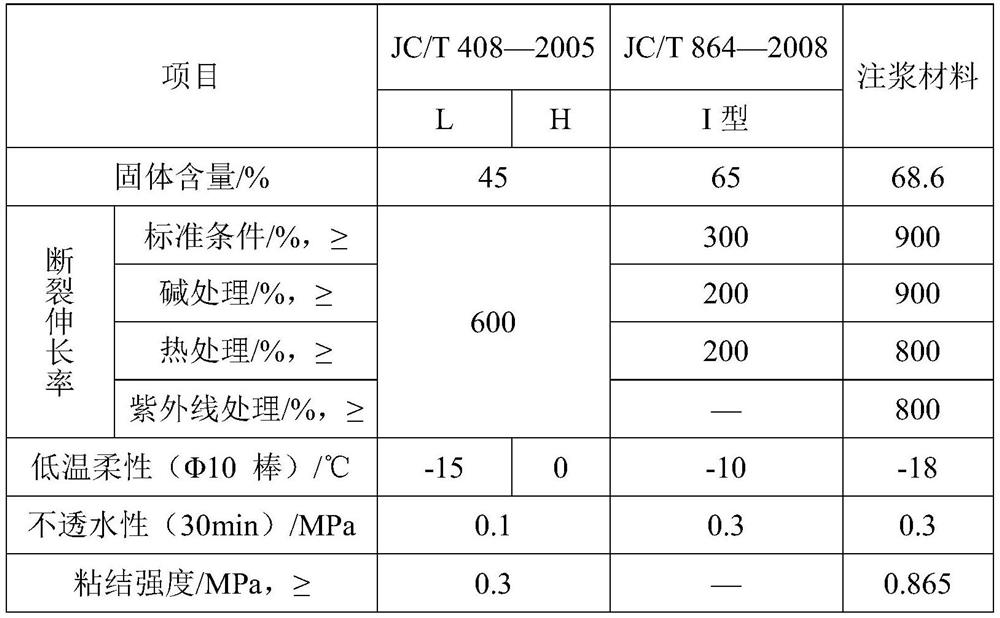

[0039] Grouting material for waterproofing construction method of balcony or roof reconstruction

[0040] Component A (parts by weight): 35 parts of anionic emulsified asphalt, 35 parts of acrylate emulsion, 1.25 parts of polycarboxylate sodium salt dispersant, 0.75 part of silicone antifoaming agent, 0.5 part of bactericide isothiazolinone derivative, methyl alcohol 20 parts of sodium silicate solution, 7 parts of natural sodium bentonite, and 0.5 part of coupling agent vinyltrimethoxysilane.

[0041] Component B (parts by weight): 35 parts of anionic emulsified asphalt, 35 parts of acrylate emulsion, 1.25 parts of polycarboxylate sodium salt dispersant, 0.75 part of silicone antifoaming agent, 0.5 part of bactericide isothiazolinone derivative, methyl alcohol 20 parts of sodium silicate solution, 7 parts of natural sodium bentonite, and 0.5 part of crosslinking agent methyltrimethoxysilane.

Embodiment 2

[0043] Component A (parts by weight): 30 parts of cationic emulsified asphalt, 30 parts of acrylate emulsion, 1.0 part of sodium polycarboxylate dispersant, 0.5 part of defoamer, 0.25 part of bactericide, 10 parts of sodium methyl silicate solution, bentonite 5 parts, and 0.25 part of the coupling agent vinyltrimethoxysilane.

[0044] Component B (parts by weight): 30 parts of cationic emulsified asphalt, 30 parts of acrylate emulsion, 1.0 part of sodium polycarboxylate dispersant, 0.5 part of silicone antifoaming agent, 0.25 part of bactericide isothiazolinone derivative, methyl alcohol 10 parts of sodium silicate solution, 5 parts of natural sodium bentonite, and 0.25 part of crosslinking agent methyltrimethoxysilane.

Embodiment 3

[0046] Component A (parts by weight): 40 parts of nonionic emulsified asphalt, 40 parts of acrylate emulsion, 1.5 parts of sodium polycarboxylate dispersant, 1.0 part of silicone antifoaming agent, 0.75 part of bactericide isothiazolinone derivative, 30 parts of potassium methyl silicate solution, 10 parts of natural sodium bentonite, and 1.0 part of coupling agent vinyltrimethoxysilane.

[0047] Component B (parts by weight): 40 parts of nonionic emulsified asphalt, 40 parts of acrylate emulsion, 1.5 parts of sodium polycarboxylate dispersant, 1.0 part of silicone antifoaming agent, 0.75 part of bactericide isothiazolinone derivative, 30 parts of potassium methyl silicate solution, 10 parts of natural sodium bentonite, and 1.0 part of crosslinking agent methyltrimethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com