Waterproof coating for toilets as well as preparation method and application of waterproof coating

A technology for waterproof coatings and toilets, which is applied in the direction of alkali metal silicate coatings, coatings, building insulation materials, etc. It can solve the problems of increasing procedures and costs, affecting the construction period, and oily coatings are not environmentally friendly, so as to improve the waterproof function and improve The effect of impermeability and waterproof performance, increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

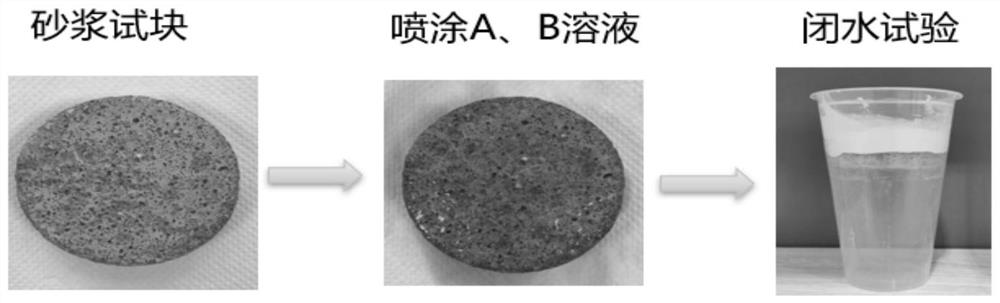

Method used

Image

Examples

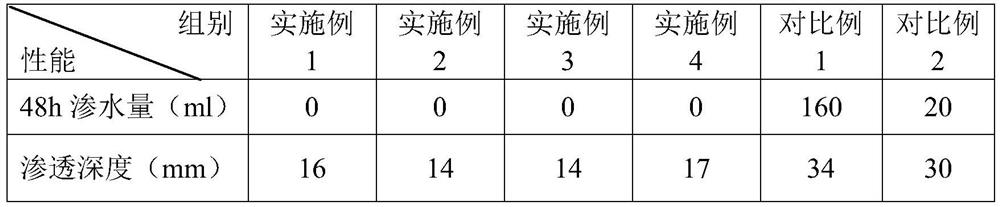

Embodiment 1

[0037] The invention discloses a waterproof coating for toilets, which comprises components A and B, and component A is calcium nitrite solution with a mass fraction of 30%.

[0038] Component B includes 56 parts of silicate solution, 0.5 parts of sodium dodecylbenzenesulfonate, 1.5 parts of EDTA-2Na, 1 part of sodium polyacrylate and 41 parts of deionized water in parts by mass, wherein the silicate solution is A mixture of sodium silicate solution and lithium silicate solution, the mass ratio of the two is 1:1;

[0039] The preparation method is as follows: turn on the mixer, add calcium nitrite and water to the mixer according to the proportion, stir evenly, and let it stand for 20-30 minutes to obtain component A; add deionized water and polyacrylic acid to another mixer according to the proportion Stir with sodium for 30 minutes to obtain a uniform solution, then add sodium dodecylbenzenesulfonate and stir for 15 minutes, then add EDTA-2Na and silicate solution, and stir ...

Embodiment 2

[0041] The preparation method of embodiment 2 is the same as that of embodiment 1, the difference is that the ratio of component B by mass fraction is: 60 parts of silicate solution, 1.0 parts of sodium dodecylbenzenesulfonate, 1.5 parts of EDTA-2Na , 1 part of sodium polyacrylate and 36.5 parts of deionized water.

Embodiment 3

[0043] The preparation method of Example 3 is the same as that of Example 1, except that the ratio of component B by mass fraction is: 65 parts of silicate solution, 1.0 parts of sodium dodecylbenzenesulfonate, and 1.5 parts of EDTA-2Na , 1 part of sodium polyacrylate and 31.5 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com