Production method for rare earth alloy magnetic powder forming body and rare-earth magnet

A technology of rare earth alloys and manufacturing methods, which is applied in the manufacture of rare earth magnets and the manufacture of rare earth alloy magnetic powder compacts. It can solve the problems of poor corrosion resistance test results, poor HAST tests, and increased frictional resistance, so as to prevent oxidation. , the degree of orientation increases, the effect of improving the degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention takes NdFeB series rare earth alloy magnetic powder as an example to illustrate the magnetic field forming process of rare earth alloy magnetic powder.

[0036] Its production process mainly includes the following processes: raw material preparation→smelting→casting→hydrogen crushing→fine pulverization→forming in a magnetic field→sintering→heat treatment→magnetic performance evaluation→evaluation of oxygen content in the sintered body.

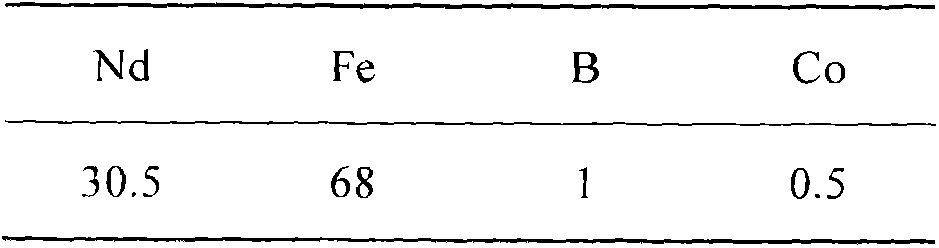

[0037] In raw material preparation process: prepare the Co of the Nd of purity 99.5%, industrial use Fe-B, industrial pure Fe, purity 99.9%, the weight ratio of each composition meets as shown in table 1:

[0038] The weight proportion of each composition of table 1

[0039]

[0040] In order to complete the above preparation composition, a total of 500Kg of raw materials were weighed and prepared.

[0041] In the smelting process: the prepared raw materials are put into a crucible made of alumina, and a high-f...

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 is listed as follows:

[0059] 1) Add methyl octanoate used as an organic additive to the pulverized powder in an amount of 0.01% of the weight of the rare earth alloy magnetic powder, and fully mix with a V-shaped mixer.

[0060] 2) Forming process in a magnetic field: Divide the powder into 10 equal parts, and use a right-angle orientation magnetic field forming machine for each part, in a 1.8T orientation magnetic field, at 0.8 ton / cm 2 Under the molding pressure of , a cube with a side length of 25mm was formed, and after forming, it was demagnetized in a magnetic field of 0.2T.

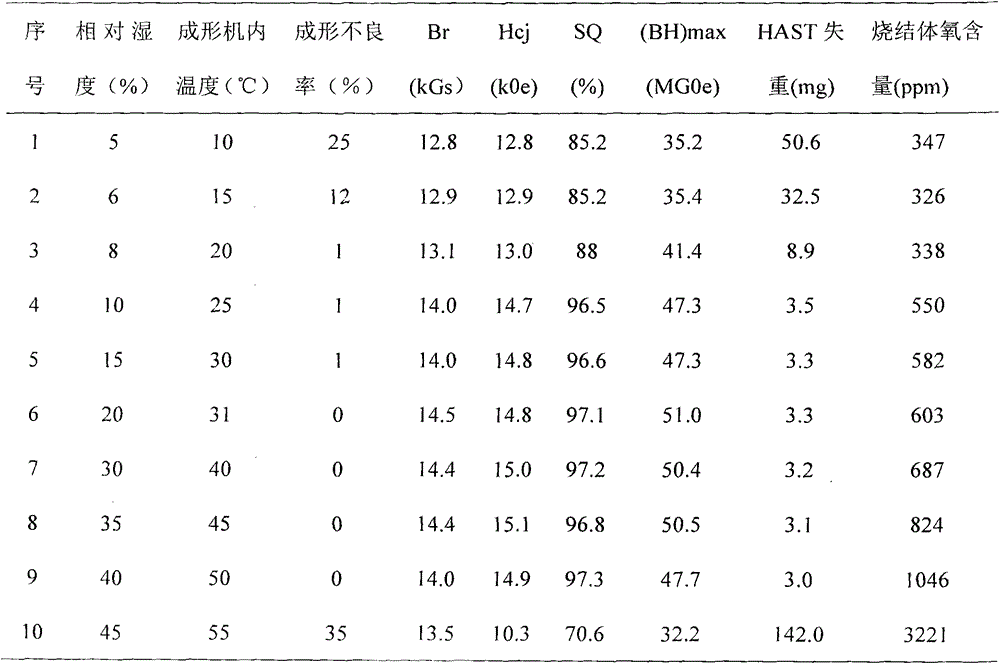

[0061] Argon atmosphere is used for molding, and the oxygen content in the argon atmosphere is fixed below 1000ppm. Humidifiers and cooling equipment are installed in the molding machine. The temperature range of the atmosphere is 10°C to 55°C, and the relative humidity range is 5% to 45%. forming in an atmosphere.

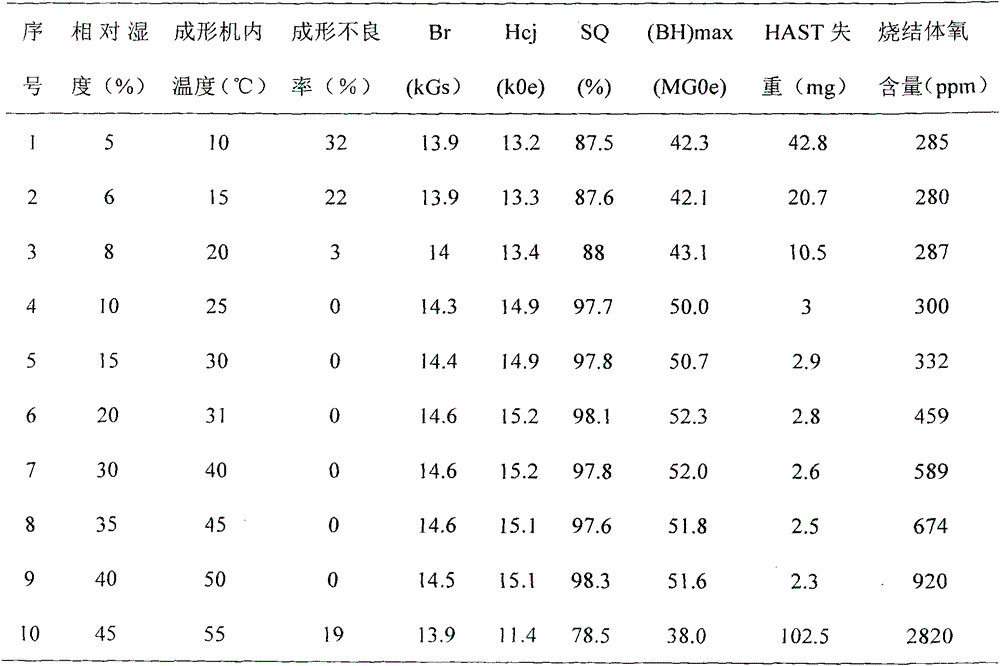

[0062] Table 3 is ...

Embodiment 3

[0066] The difference between embodiment 3 and embodiment 1 is listed as follows:

[0067] 1) Add methyl octanoate to the pulverized powder in an amount of 1.5% of the weight of the rare earth alloy magnetic powder, and then fully mix with a V-shaped mixer.

[0068] 2) Forming process in a magnetic field: Divide the powder into 10 equal parts, and use a right-angle orientation magnetic field forming machine for each part, in a 1.8T orientation magnetic field, at 0.3 ton / cm 2 Under the molding pressure of , a cube with a side length of 25mm was formed, and after forming, it was demagnetized in a magnetic field of 0.2T.

[0069] Argon atmosphere is used for molding, and the oxygen content in the argon atmosphere is fixed below 1000ppm. Humidifiers and cooling equipment are installed in the molding machine. The temperature range of the atmosphere is 10°C to 55°C, and the relative humidity range is 5% to 45%. forming in an atmosphere.

[0070] Table 4 is a comparative table of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com