Micro emulsion type cutting liquid with high lubrication, low foam and long service life

A low-foaming, long-life technology, applied in the direction of lubricating compositions, etc., can solve the problems of poor air thermal conductivity, reduced cooling effect, easy volatilization, etc., and achieve the effect of less emulsifier content, easy management, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

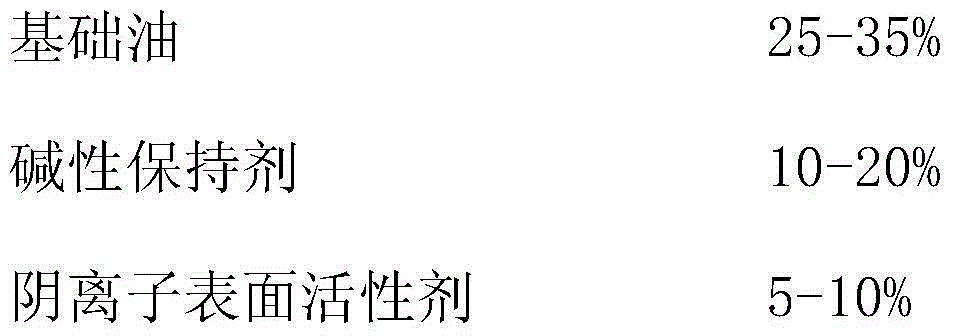

[0023] A microemulsion cutting fluid with high lubricity, low foam and long service life, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0024]

[0025]

[0026] Among them, the base oil is paraffin base oil; the alkaline retaining agent is one or more of isopropanolamine, triethanolamine, monoethanolamine, alkanolamine, 2-amino, 2-methyl propanol, such as isopropanolamine Mixture of propanolamine, triethanolamine and alkanolamine; anionic surfactant is ether carboxylic acid; rust inhibitor is boric acid, sebacic acid, amide caproic acid triethanolamine salt, ammonium sulfonate, boric acid ester and oleic acid One or a mixture of two or more of them, such as a mixture of boric acid and sebacic acid; the coupling agent is diethylene glycol butyl ether, dipropylene glycol butyl ether, propylene glycol phenyl ether, isomerized cetyl alcohol, tall oil One or several kinds of acids, such as a mixture o...

Embodiment 2

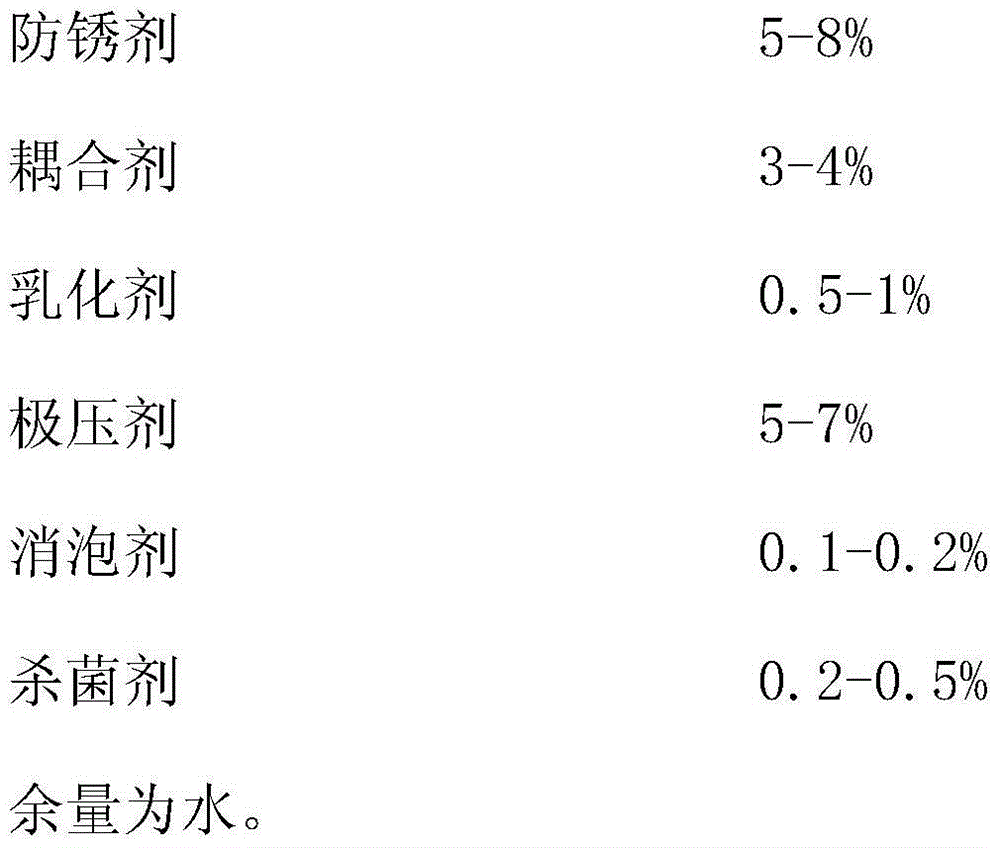

[0028] A microemulsion cutting fluid with high lubricity, low foam and long service life, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0029]

[0030] Among them, the base oil is naphthenic oil; the alkaline retaining agent is a mixture of monoethanolamine, alkanolamine, and 2-amino, 2-methylpropanol; the anionic surfactant is ether carboxylic acid; the rust inhibitor is decane acid, amide caproic acid triethanolamine salt, and oleic acid; the coupling agent is a mixture of diethylene glycol butyl ether, propylene glycol phenyl ether, and tall oil acid; the emulsifier is alkoxy fatty alcohol; the extreme pressure agent is phosphoric acid ester; defoamer is modified dimethyl siloxane; fungicide is methyl benzotriazole.

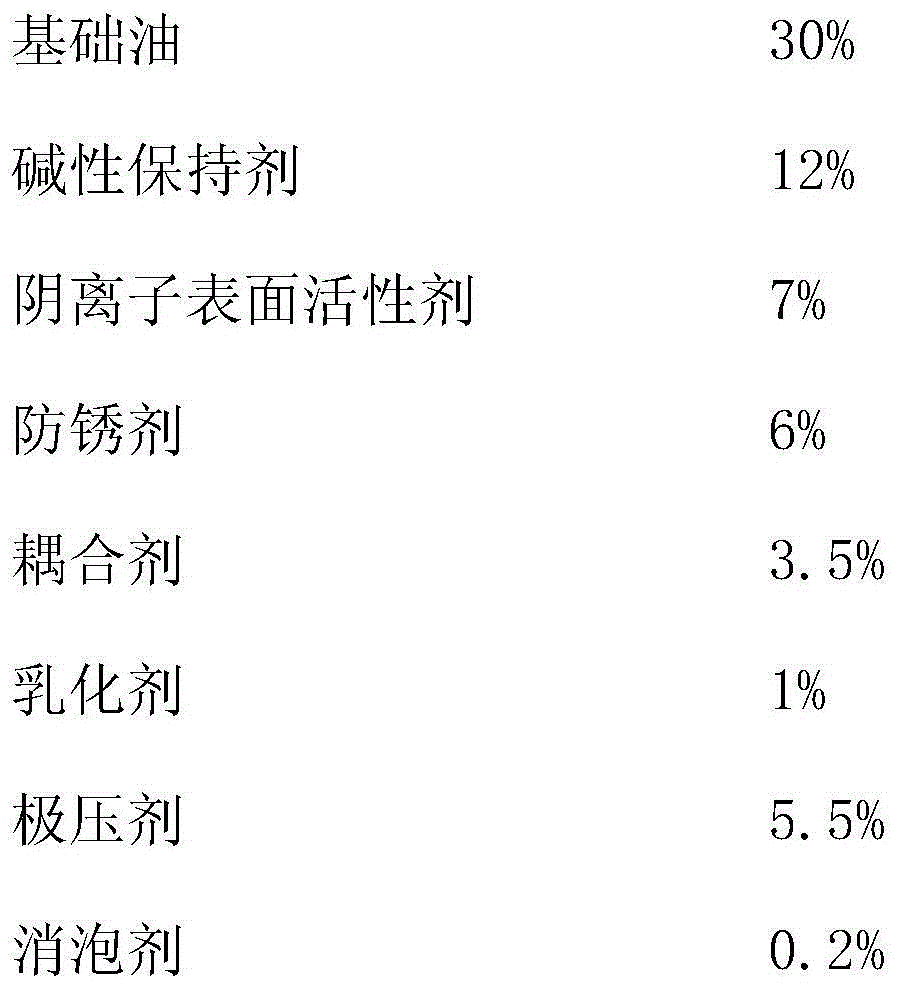

Embodiment 3

[0032]

[0033] Among them, the base oil is paraffin oil; the alkaline retaining agent is alkanolamine; the anionic surfactant is ether carboxylic acid; the antirust agent is a mixture of ammonium sulfonate, boric acid ester, and oleic acid; the coupling agent is propylene glycol The mixture of phenyl ether and isomerized cetyl alcohol; the emulsifier is alkoxy fatty alcohol; the extreme pressure agent is phosphoric acid ester; the defoamer is polyether; the fungicide is methyl benzotriazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com