Novel condensing lubricant oil and preparation method thereof

A lubricating oil, a new type of technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems of poor permeability, increased movement resistance, and inability to participate in the internal lubrication of parts, and achieve low volatility, Effects of extended service life and excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

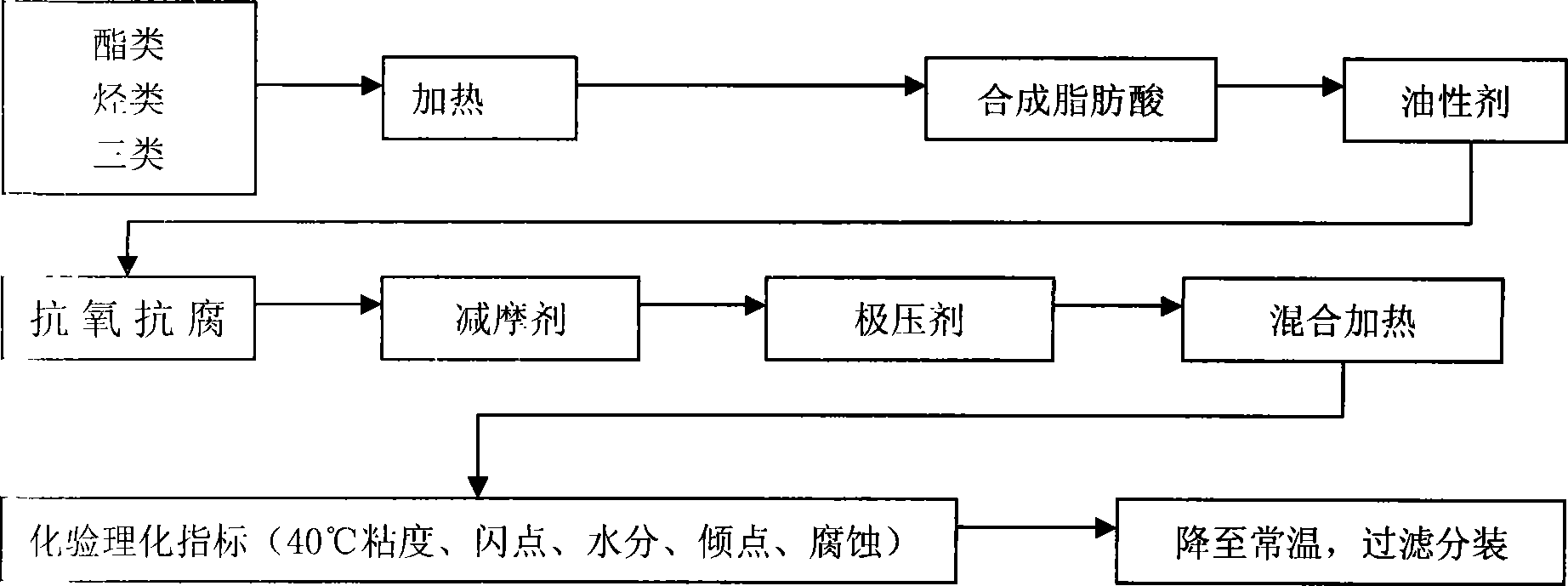

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Weigh the following raw materials: NP343 5kg, PA08 30kg and 150N 30kg, add them to the container, heat and mix, increase the temperature to 70℃ and continue heating for 50 minutes, then add azelaic acid 3kg, T405A3kg, T203 1kg, boron nitrogen Compound 0.5kg and T361A 1kg were mixed and heated for 40 minutes, and the physical and chemical indexes were tested. After reaching the indexes, the temperature was lowered to room temperature, and then filtered and packaged.

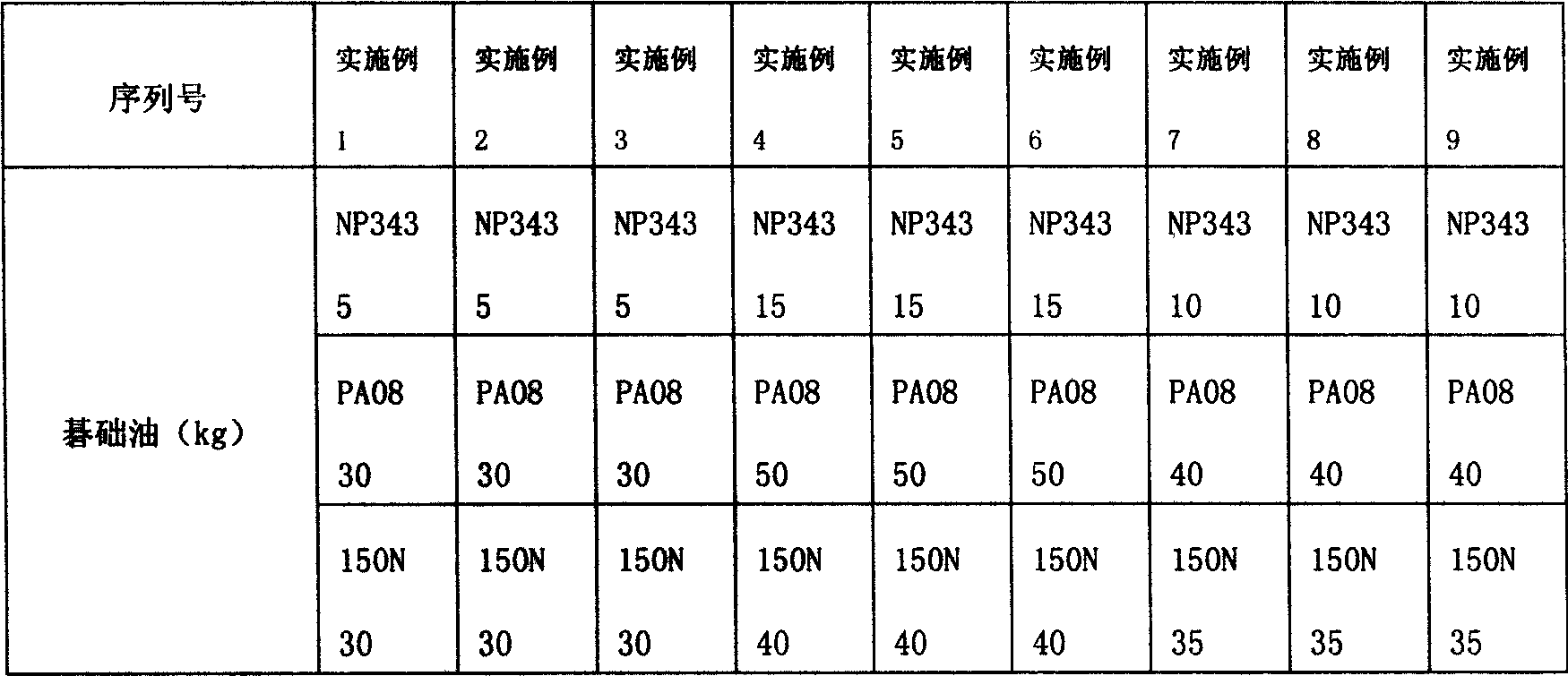

[0019] Table 1 and Table 2 are a list of examples of the present invention.

[0020] Table 1 is a list of embodiments of the present invention

[0021]

[0022]

[0023] Table 1

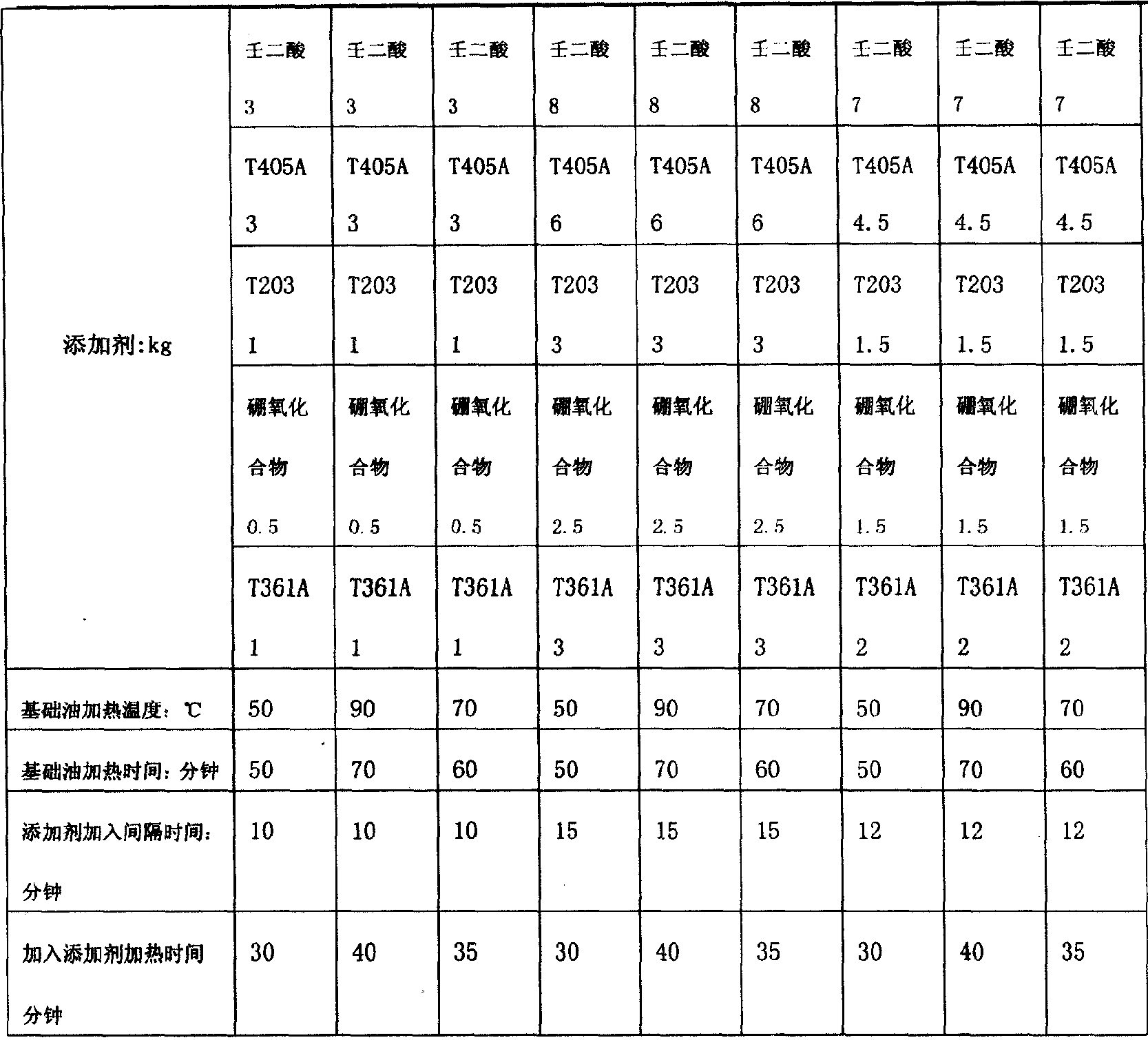

[0024] Table 2 is a list of embodiments of the present invention

[0025]

[0026]

[0027] Table 2

[0028] The esters in the above example can be replaced with one or more of NP343, NP372 and P81, the hydrocarbons can be replaced with one or more of PA08, PA06 and PA012, and the three types of oil can be replaced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com