Method for anti-cracking in hogging moment area of steel-concrete combined beam

A negative bending moment zone, concrete technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of structural durability, unable to prevent concrete cracking, etc., to achieve the effect of controlling cracking, increasing construction, and simplifying the installation of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

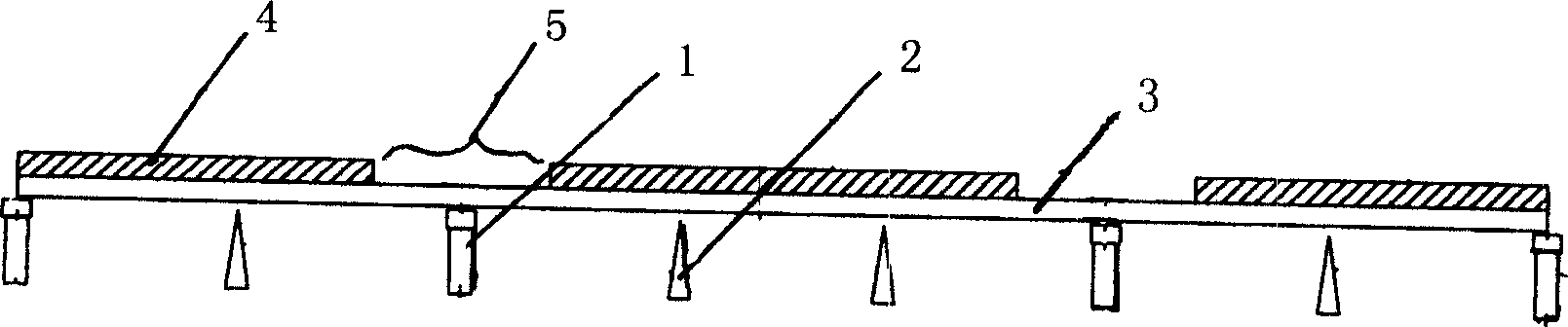

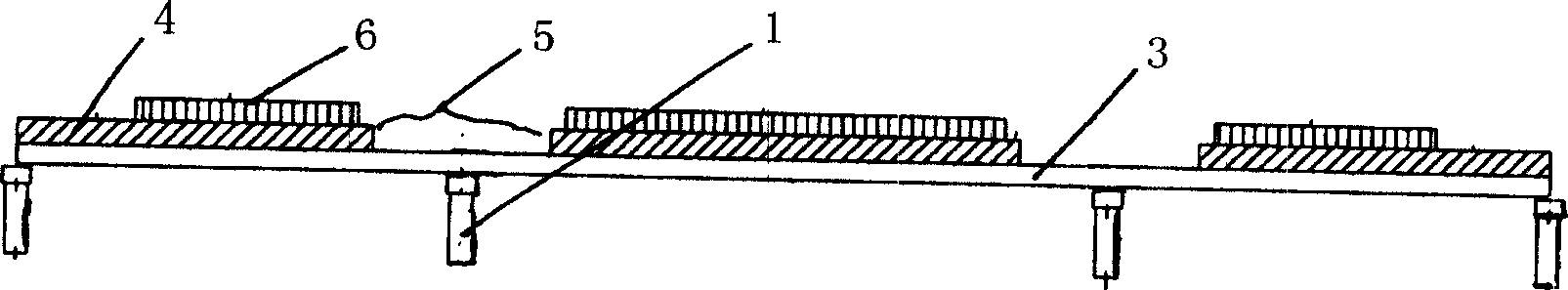

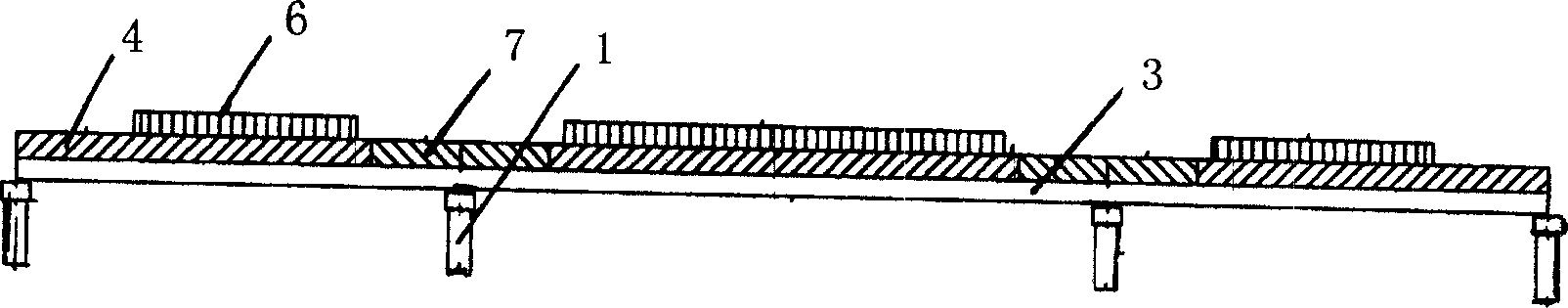

[0021] The invention provides a method for anti-cracking in the negative moment zone of a steel-concrete continuous composite beam. The so-called positive bending moment area is the middle part of the bridge that bends downward when it is under compression between the two piers 1; The steel girders 3 on both sides of the bridge are pushed upward by the pier 1, and this part is called the negative bending moment area. The concrete on the steel beams 3 on both sides of the bridge pier 1 in the negative bending moment zone is the concrete wing plate in the negative bending moment zone. When the concrete wing in the negative bending moment area is bent upward, the concrete wing is easy to crack. The method to overcome cracking is to pour concrete in the positive moment area and negative moment area of the steel-concrete continuous composite beam in two steps, and at the same time arrange the preloading load or ground anchor loading method in the positive moment area to facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com