Construction process for pretension carbon fiber cloth reinforced concrete beam

A technology of carbon fiber cloth and concrete beams, which is applied in building maintenance, processing of building materials, construction, etc., can solve the problems of large number of parts, high labor costs, no maturity, etc., and achieve simple tensioning and anchoring systems, tensioning The effect of light and compact equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

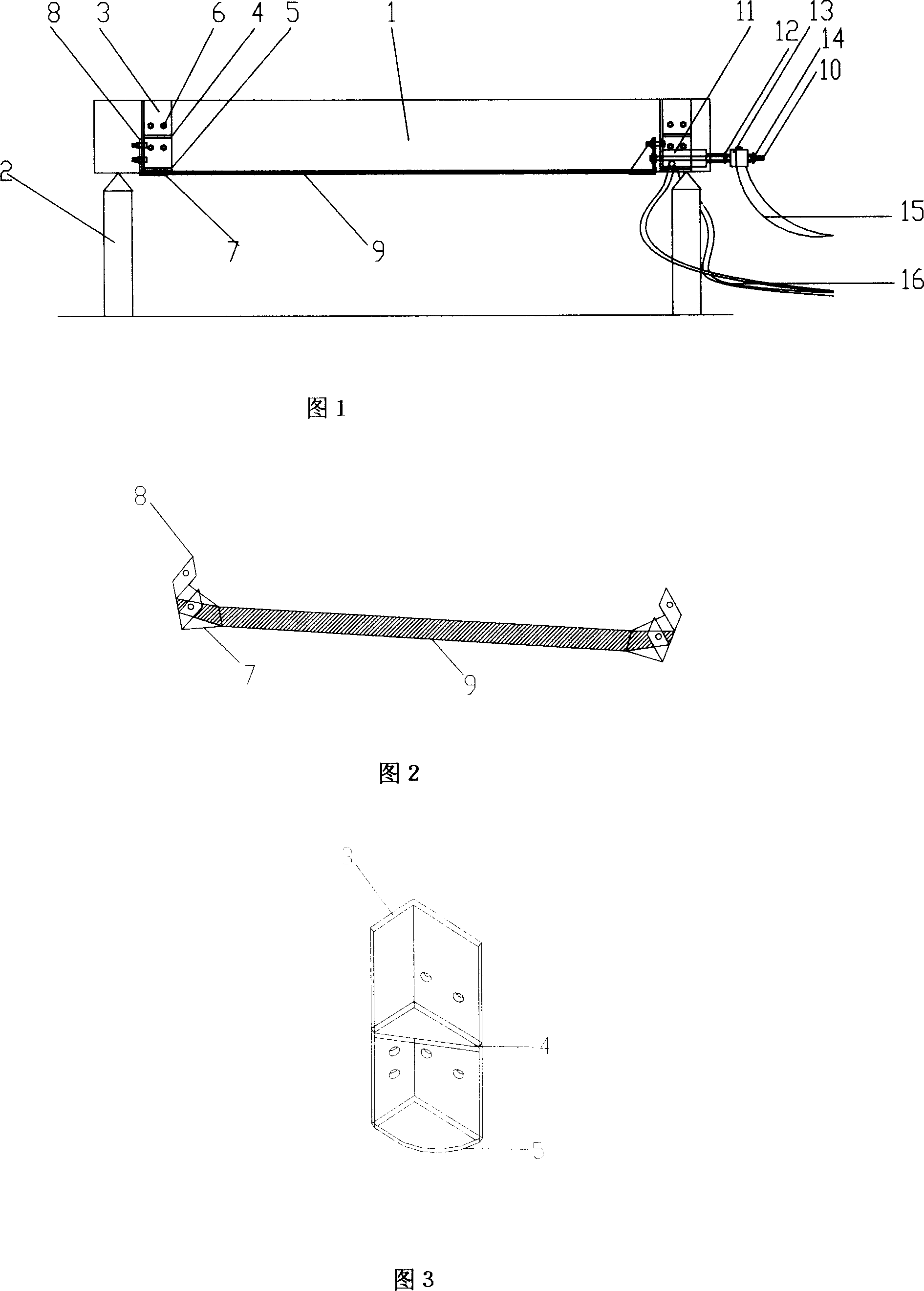

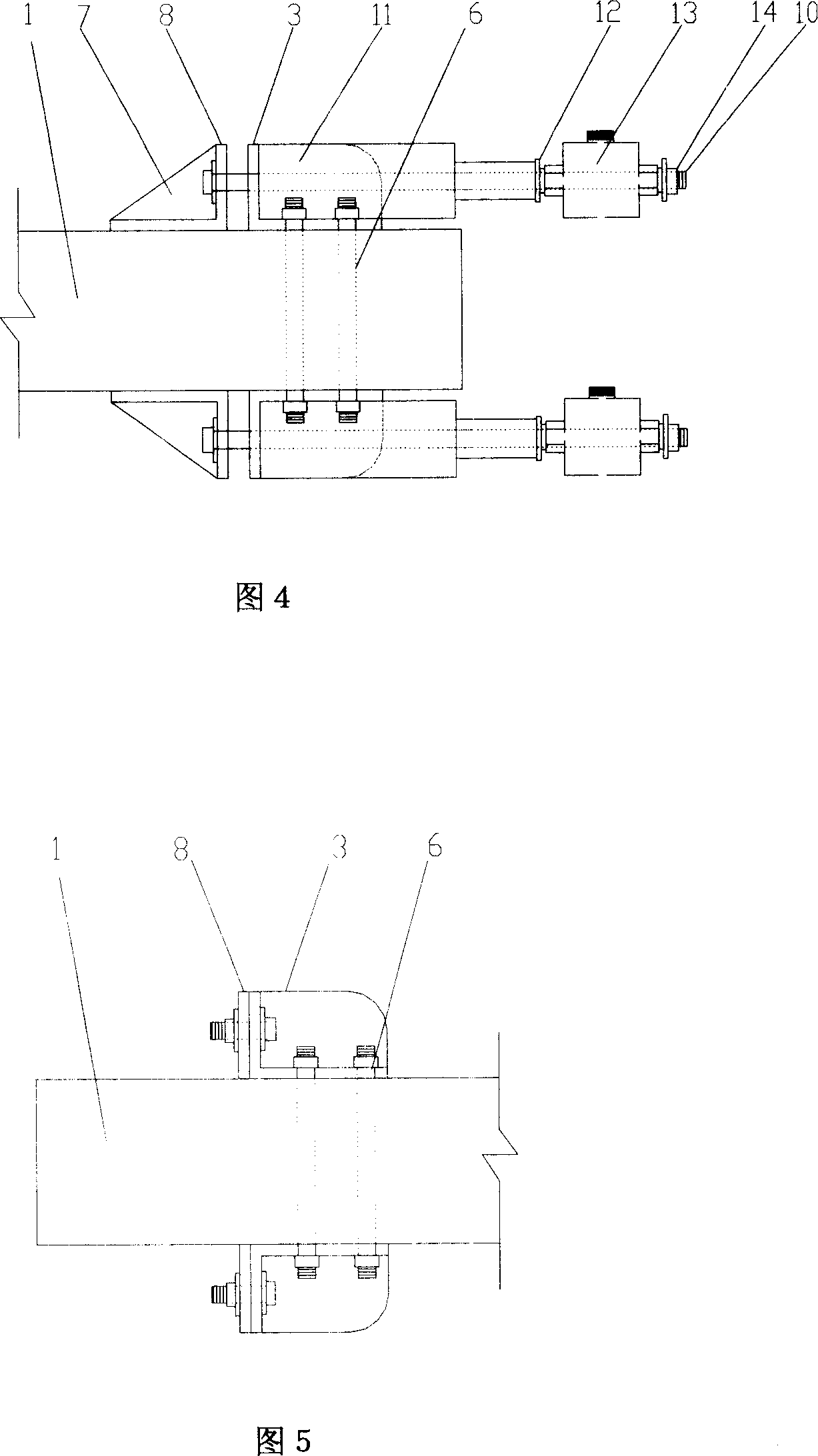

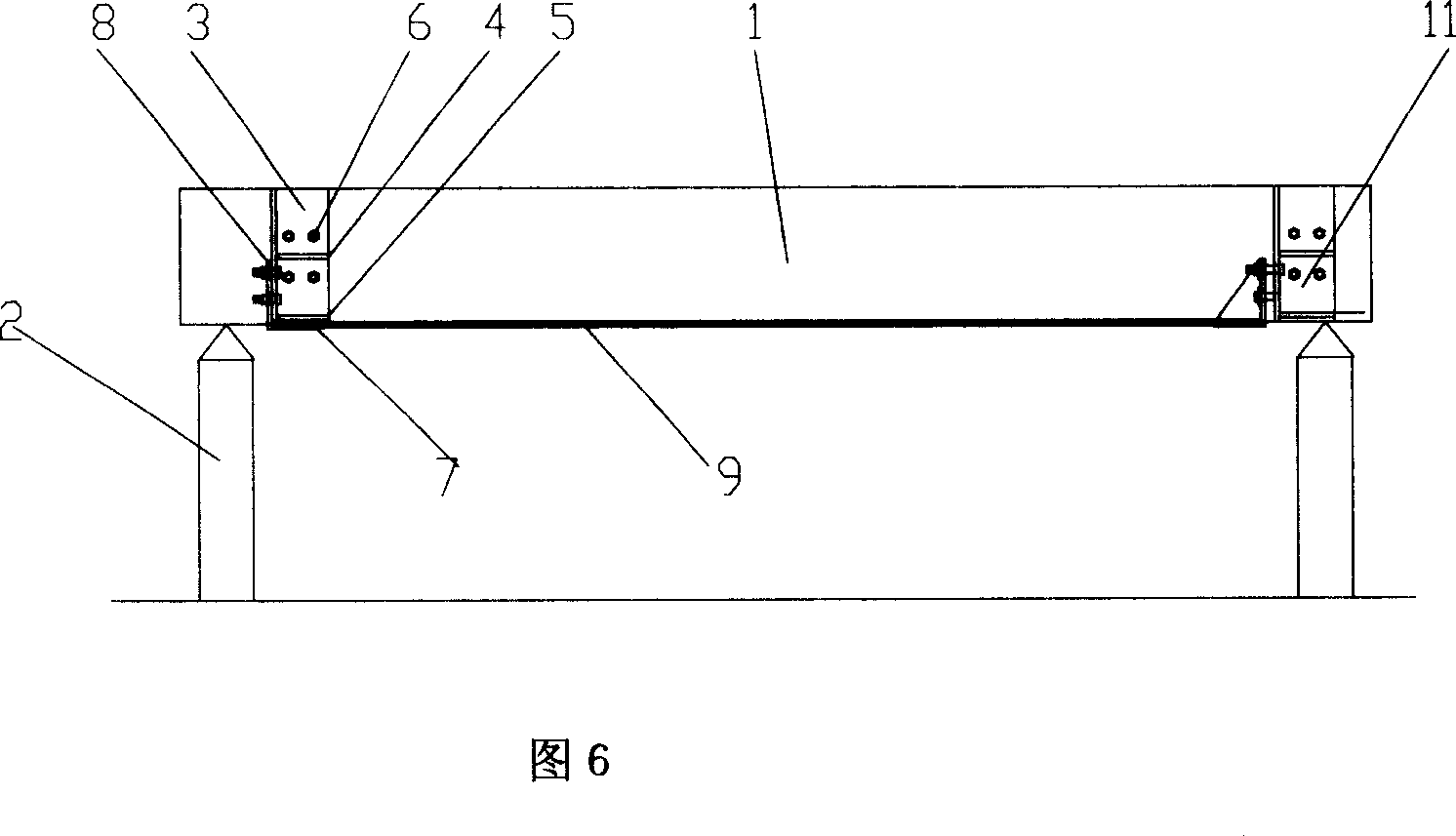

[0019] The two ends of the concrete beam 1 on the bracket 2 are installed in pairs corresponding to the angle steel 3 according to the designed position, and each pair of angle steel uses four bolts 6 to penetrate the beam section, and the middle part of the angle steel has a reinforcing rib 4 and a supporting plate 5 , the distance between the two anchor vertical plates 8 is the same as the width of the concrete beam section, calculate the use length of the CFRP cloth 9, wind the CFRP cloth to the fixed end and the tension end anchor base plate 7 respectively and paste them, and then, polish the concrete At the bottom of the beam, apply primer to the bottom of the beam, install the anchor with CFRP cloth on the beam, the concrete beam 1 is located between the two anchor vertical plates 8, the bottom of the beam is attached to the bottom plate of the anchor, and each of the anchor The vertical plates are fixedly connected with the angle steel 3 with bolts 6 respectively, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com