Method for detecting concrete beam anchor lower prestress and device for realizing method

An anchored prestressed, concrete beam technology, applied in the field of prestressed engineering test devices, can solve problems affecting the service effect and life of prestressed concrete components, under-tensioned or over-tensioned, and tension loss, etc., to prevent Sudden destruction accidents, avoiding waste, and standardizing the effect of quality control behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

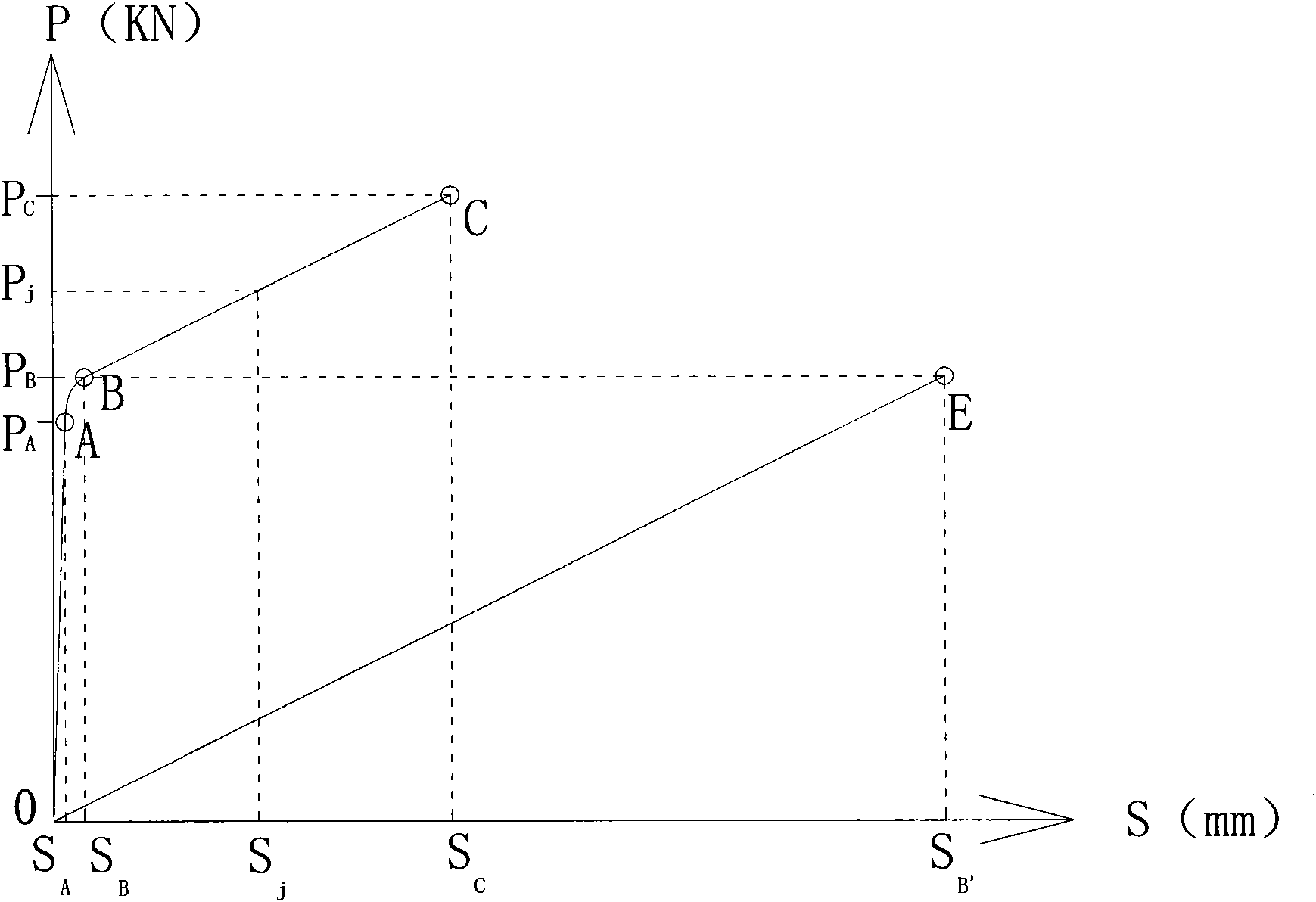

[0024] The detection device of the present invention is aimed at detecting the anchorage prestress value after the anchor cable is stretched and locked in the second stage of the anchoring project. The principle of this detection technology is to re-tension the anchor cables that have been locked but not grouted, and determine the prestress value of the bridge under anchor according to the P-S curve of the re-stretch. Engineering tension comparison, and then judge whether the quality of the tensioned anchor cable meets the specification requirements.

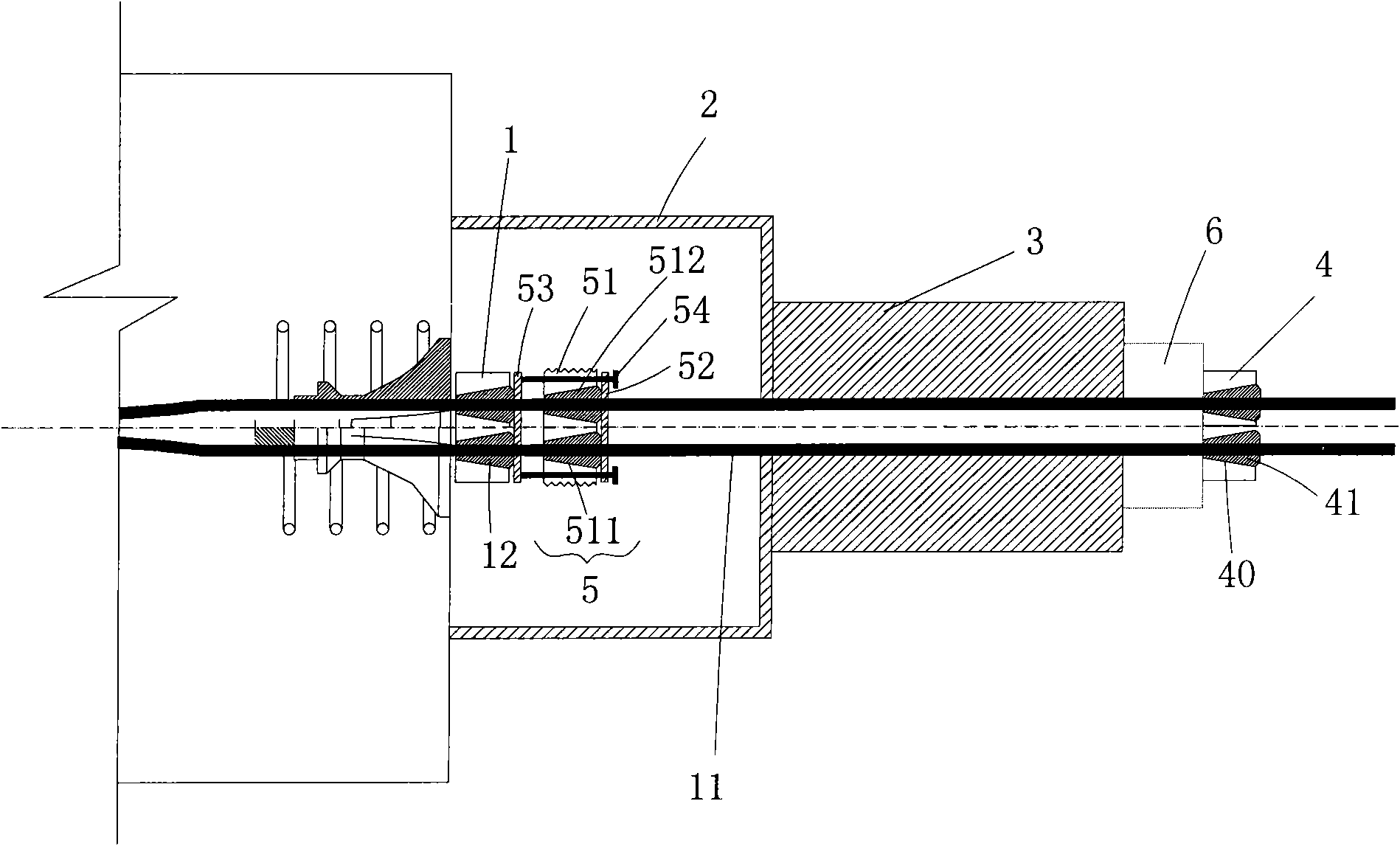

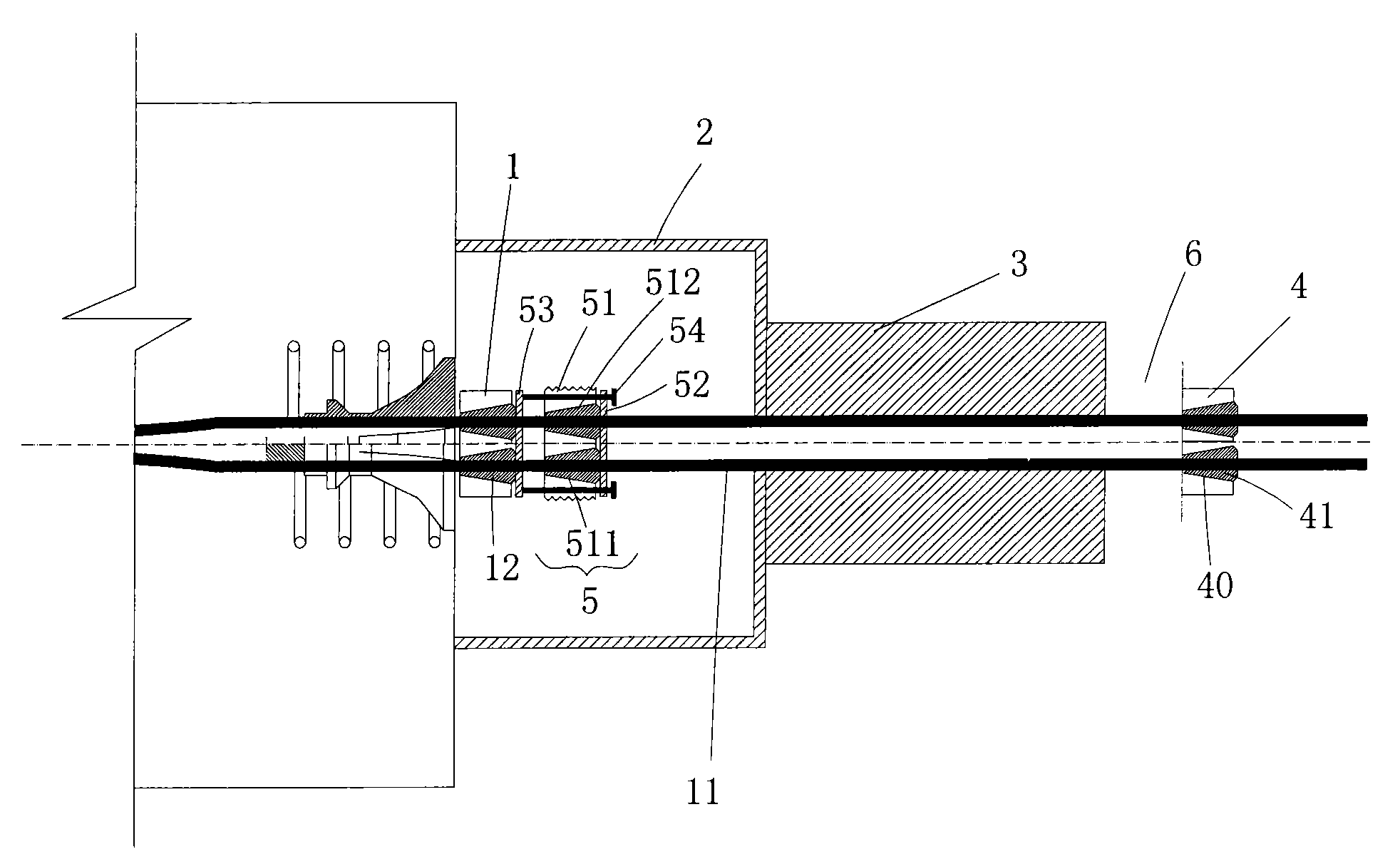

[0025] In order to realize above-mentioned detection method, the present invention has designed following detection device, as figure 1 As shown, the detection device mainly includes: a jack 3 for tensioning the anchor cable 11 installed in series on the anchor cable, a reaction cylinder 2 for providing a reaction force to the jack 3, a tool anchor 4 for locking the anchor cable 11, and a limiter. The limit assembly 5 of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com