Assembly integral type concrete frame structure of dry-wet mixed connection of nodes and construction method

A frame structure and mixed connection technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of inability to realize beam plastic hinge transfer, complex construction technology, and weak energy consumption of the structure, and shorten the standard laminar flow. The effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

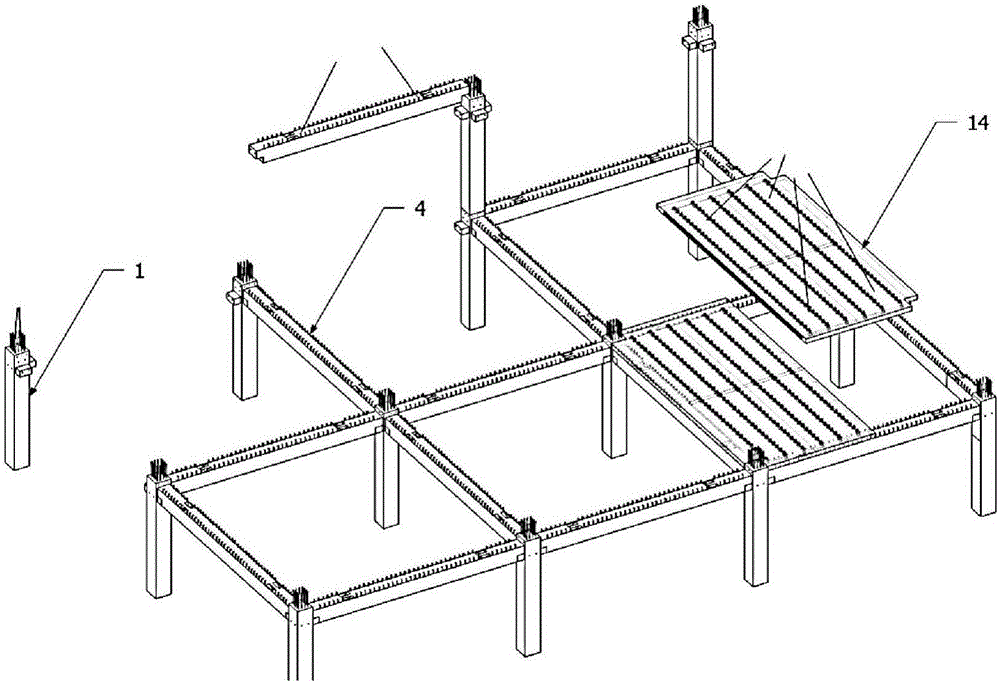

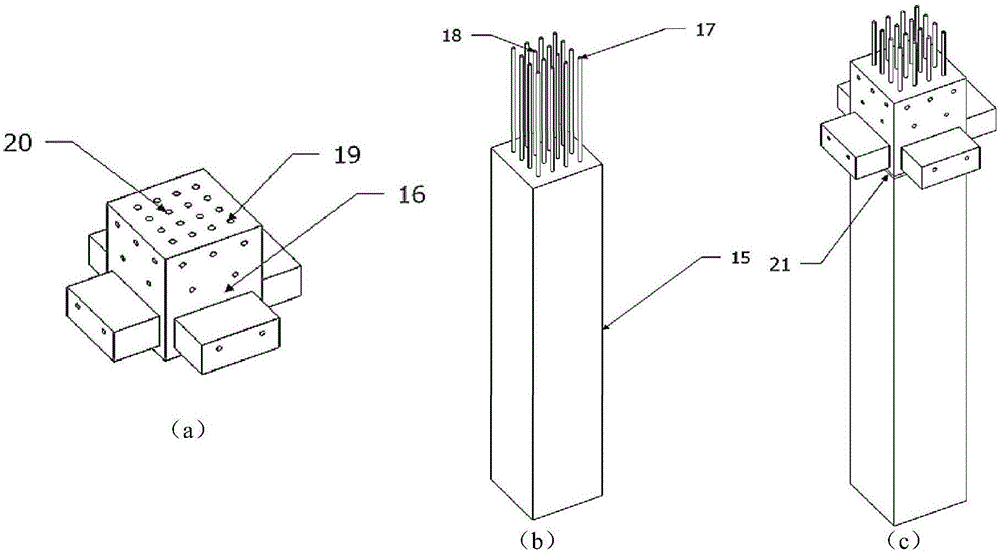

[0026] Example: such as figure 1Shown is a two-story, two-story, three-span precast concrete frame structure, which includes segmental single-layer precast columns 1, precast concrete beams 4, precast concrete slabs 14, and post-cast concrete laminated surfaces 10, in which segmental single-layer The prefabricated column 1 is composed of a precast concrete column node section 16 and a concrete column lower section 15 .

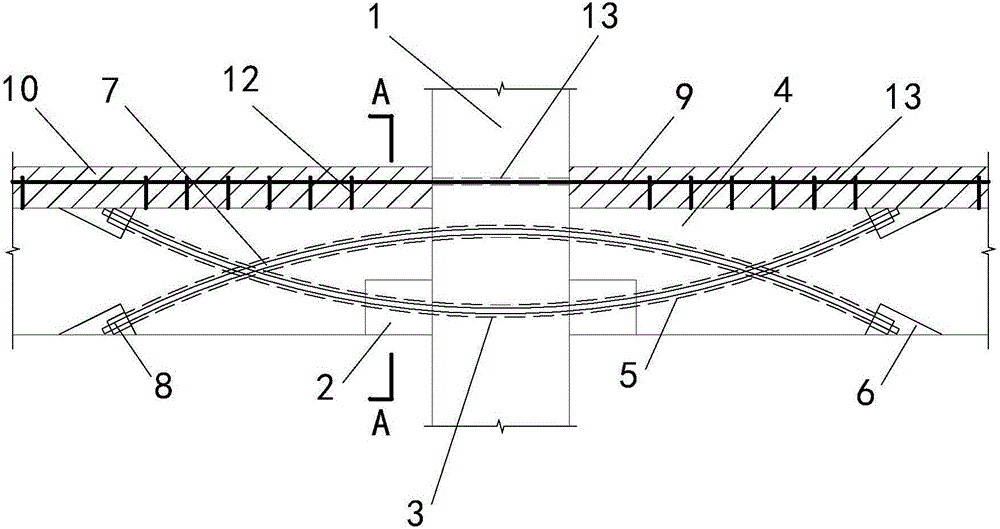

[0027] During the construction stage, the precast concrete beam 4 forms a cross beam system, the beam end of the precast concrete beam 4 is provided with a rebate, and the side of the node column section of the precast concrete column 1 is provided with a corbel 2 matching the rebate, such as image 3 shown. The precast concrete column 1 and the precast concrete beams 4 on both sides thereof cooperate with the corbels 2 through the tongue and groove, and are stretched through the prestressed tendons 7 to form a dry-connected frame structure without floor sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com