Method for reinforcing concrete beam by prestressed carbon fiber plate and steel-concrete

A concrete reinforcement and carbon fiber board technology, which is applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems that old and new concrete cannot work together effectively, the concrete cannot be compacted by vibration, and the quality of concrete cannot be guaranteed, so as to improve the bearing capacity and predict Effect of avoiding stress loss and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

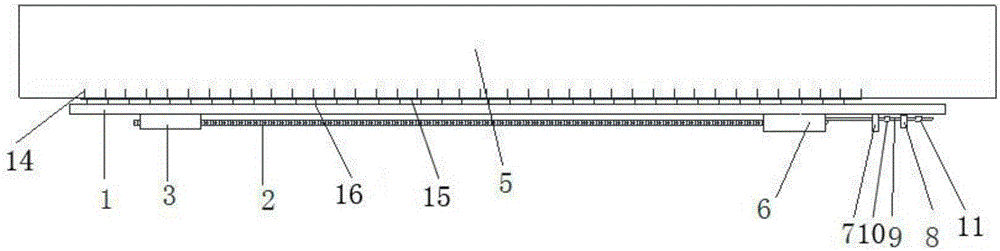

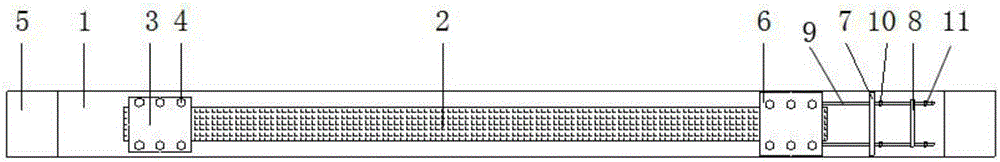

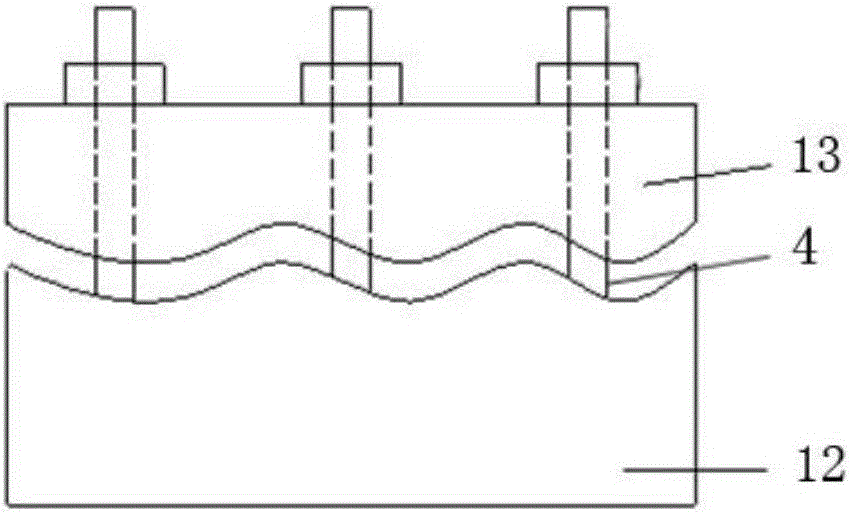

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] Such as Figure 1-4 Shown, a kind of prestressed carbon fiber plate and steel-concrete strengthen the method for concrete beam, comprise the steps:

[0025] 1. Process the concrete beam 5 to be strengthened, chisel off the concrete protective layer on the bottom surface of the concrete beam until the steel bar layer is exposed; then drill holes and plant bars after cleaning, and the implanted steel bar 14 is fixed with structural glue. The layout is 10cm in the vertical direction and 5cm in the horizontal direction; after the steel bars planted are fixed, a layer of steel mesh 15 is arranged, and the steel mesh is fixed on the steel bars planted by tie wire;

[0026] 2. The blanking and processing of the steel plate 1 is firstly cut according to the design size of the steel plate, using factor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com