Construction method of support system for templates of concrete beams and slabs

A technology of concrete beams and support systems, which is applied in the field preparation of formwork/formwork/work frames, building components, construction, etc., and can solve the problem that beam formwork support poles and slab formwork support poles cannot be shared, and beam slab formwork Difficulty in erecting supporting poles, difficulty in connecting vertical poles and horizontal poles, etc., to achieve the effects of easy control of construction quality, saving in consumption, and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

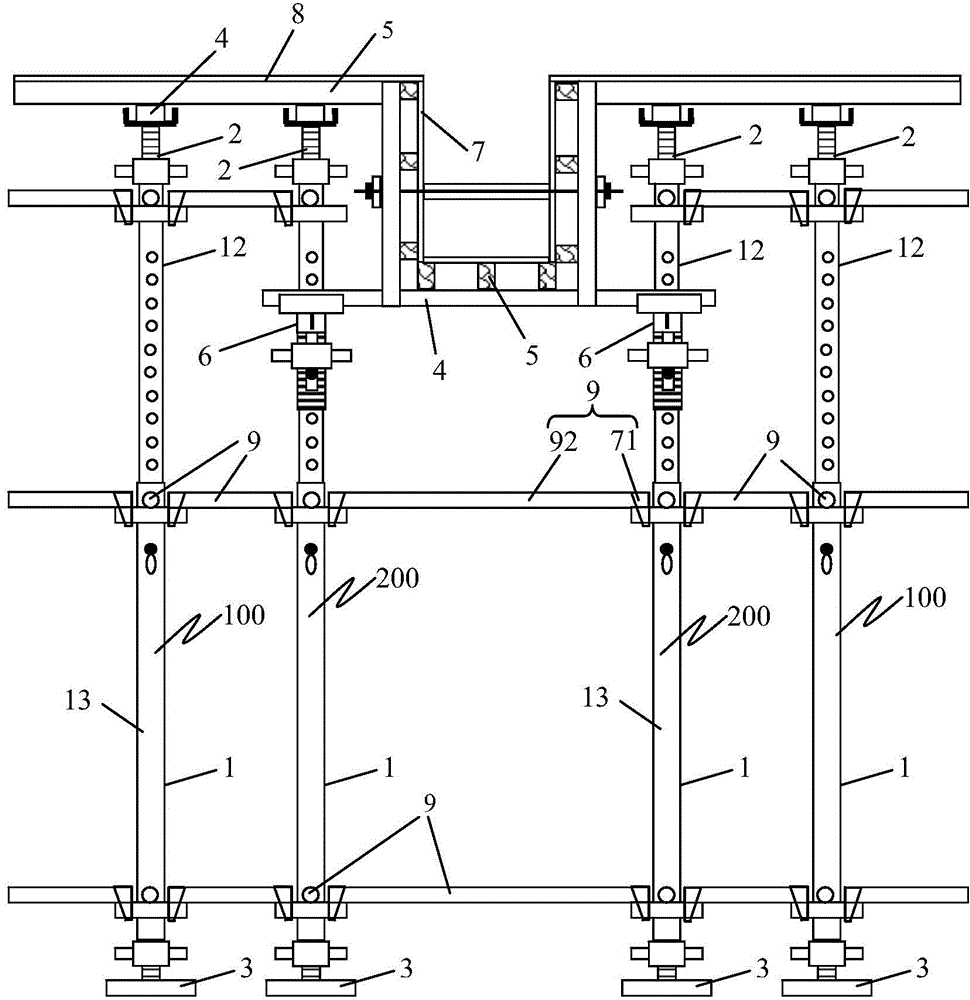

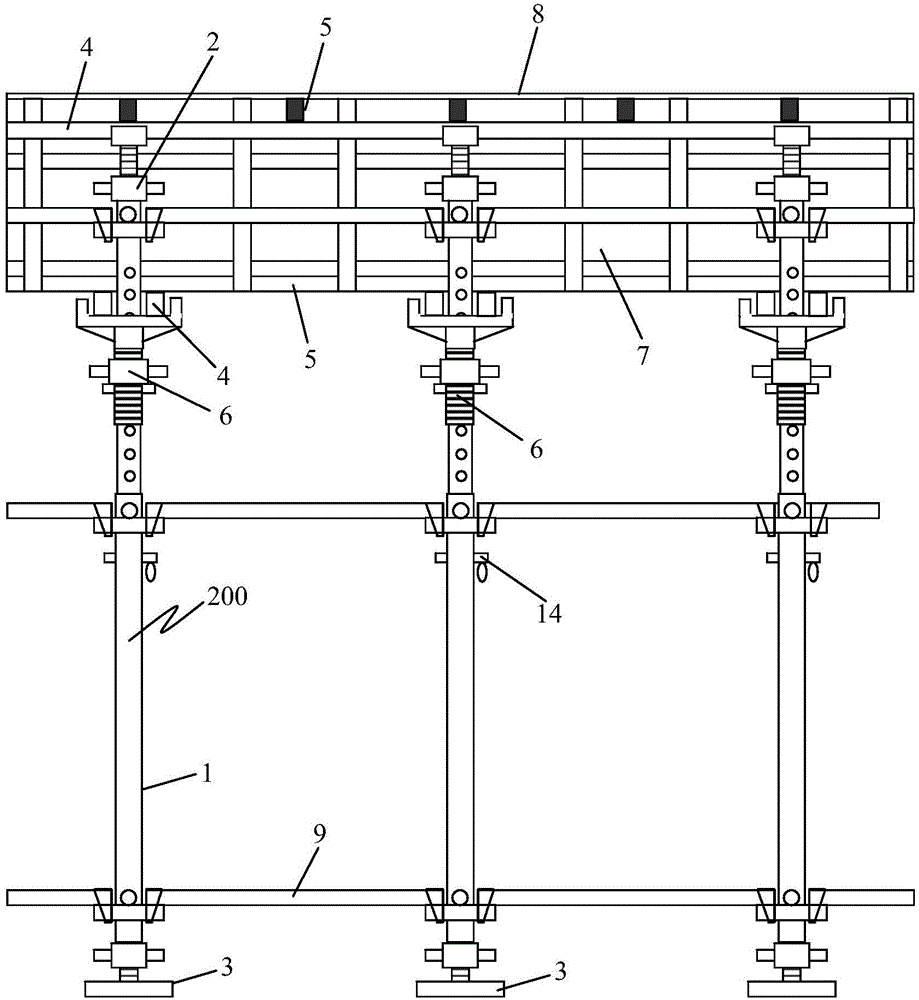

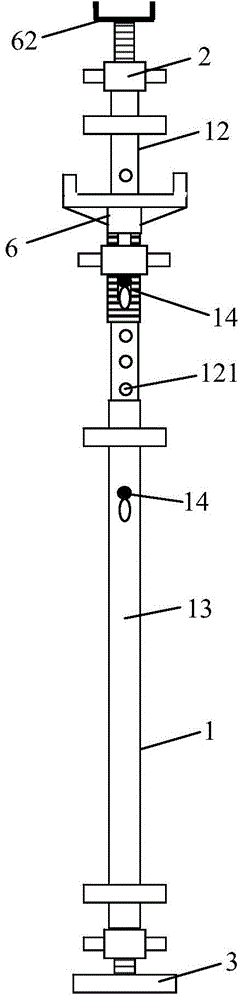

[0039] see Figure 1 to Figure 10 As shown, a construction method of a concrete beam slab formwork support system of the present invention, the support system includes a plurality of groups of support rod assemblies, each group of support rod assemblies includes: a first support rod assembly 100 and a second support rod assembly 200; The first support rod assembly 100 includes a telescopic support pole 1, an adjustable jack 2, an adjustable base 3, and a joist 4; the telescopic support pole 1 is provided with a plurality of trays 11; the first The second support rod assembly 200 is provided with a girder 6 on the telescopic support pole 1 of the first support rod assembly 100; A plurality of holes 121 are arranged at a certain distance from top to bottom, a tray 11 is provided near the upper end of the inner casing 12; a tray 11 is respectively set near the upper and lower ends of the outer casing 13, and a through hole 131 is arranged below the upper tray 11 of the outer casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com