Multipoint loading fatigue tester controlled by microcomputer

A fatigue testing machine and microcomputer control technology, which is applied in the field of testing machines, can solve the problems of high precision requirements, many testing items, and large volume, and achieve the effects of high testing precision, complete control functions, and good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

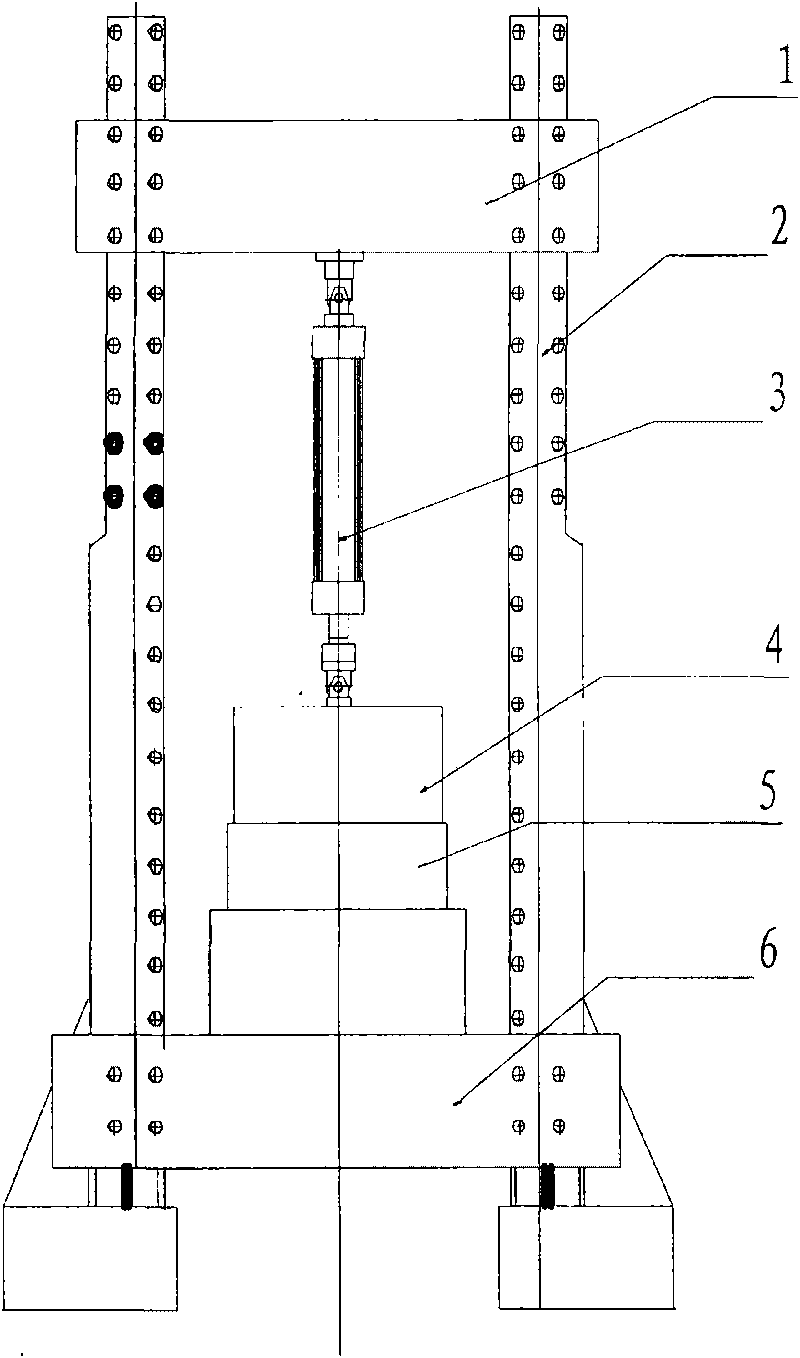

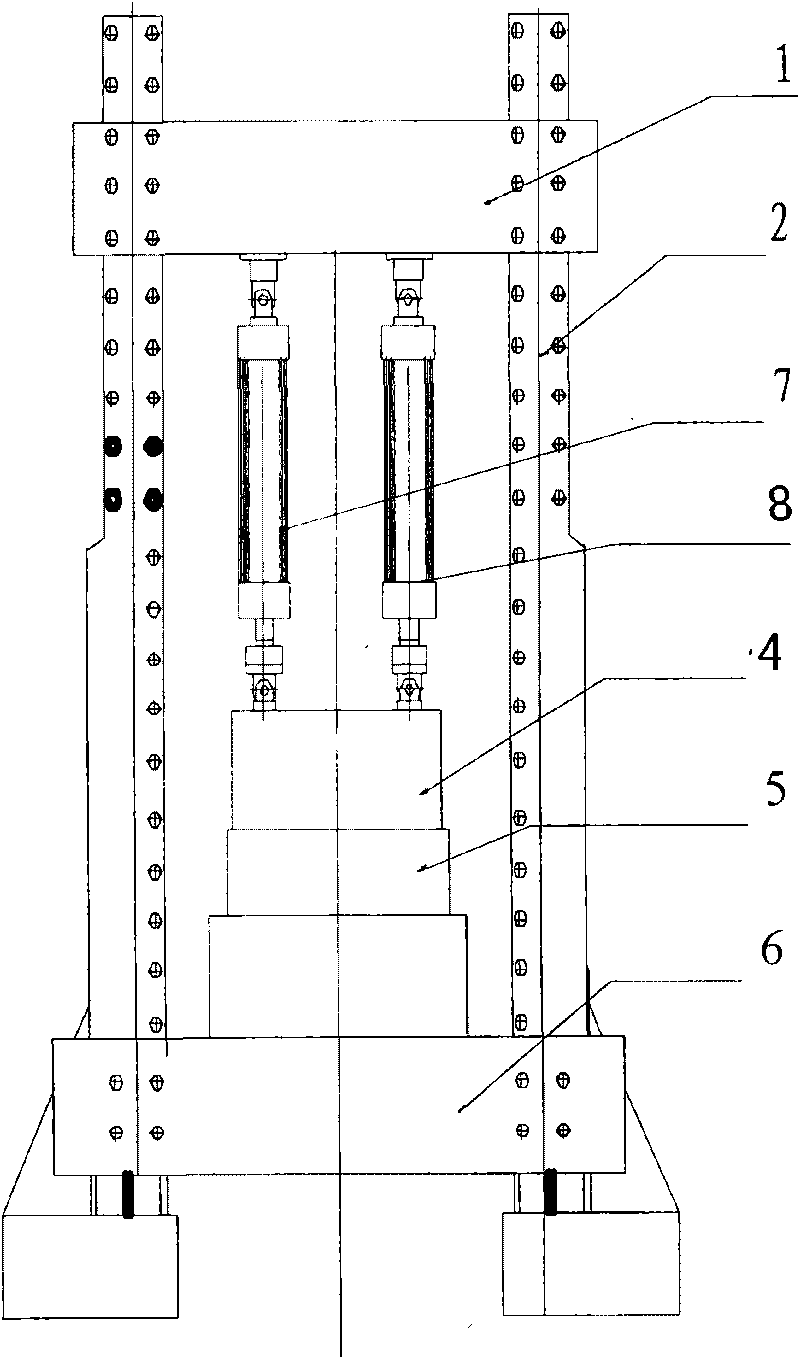

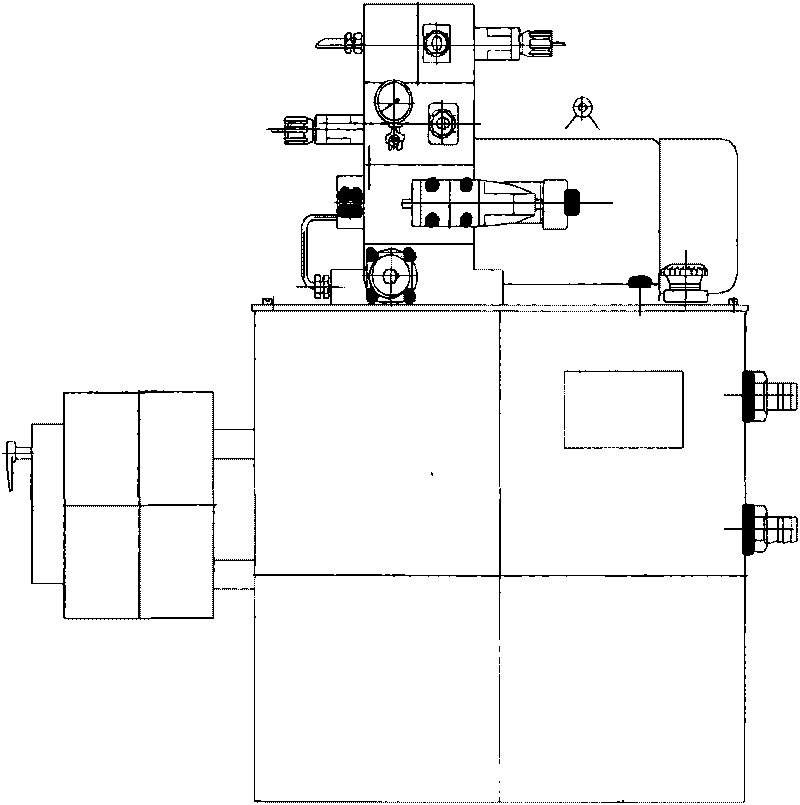

[0016] The specific embodiment of the present invention is illustrated below in conjunction with accompanying drawing, microcomputer control multi-point loading fatigue testing machine comprises main frame, loading mechanism, measuring system, hydraulic system and control system, and main frame comprises carrying frame 2 and the annex that is contained on the frame, so The load-bearing frame 2 is a reaction frame balanced by the ground trough, the base of the frame is placed in the ground trough of the foundation, the machine base moves in the ground trough, and the column of the frame is adjusted to be in a balanced state. The load-bearing frame 2 has two square columns , The square column is surrounded by a box-shaped welded A3 steel plate, and the internal steel reinforcement is welded. The upper part of the column is small and the lower part is large. The upper part of the column is equipped with a moving beam 1, and the lower part is equipped with a bearing beam 6, on whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com