Mineral separation process capable of increasing gold recovery in gold tailings

A mineral processing method and technology of recovery rate, which is applied in the field of mineral processing to improve the recovery rate of gold in gold tailings, can solve the problems of low gold recovery rate, serious environmental pollution, high cost, etc., and achieve high recovery rate, wide process adaptability, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

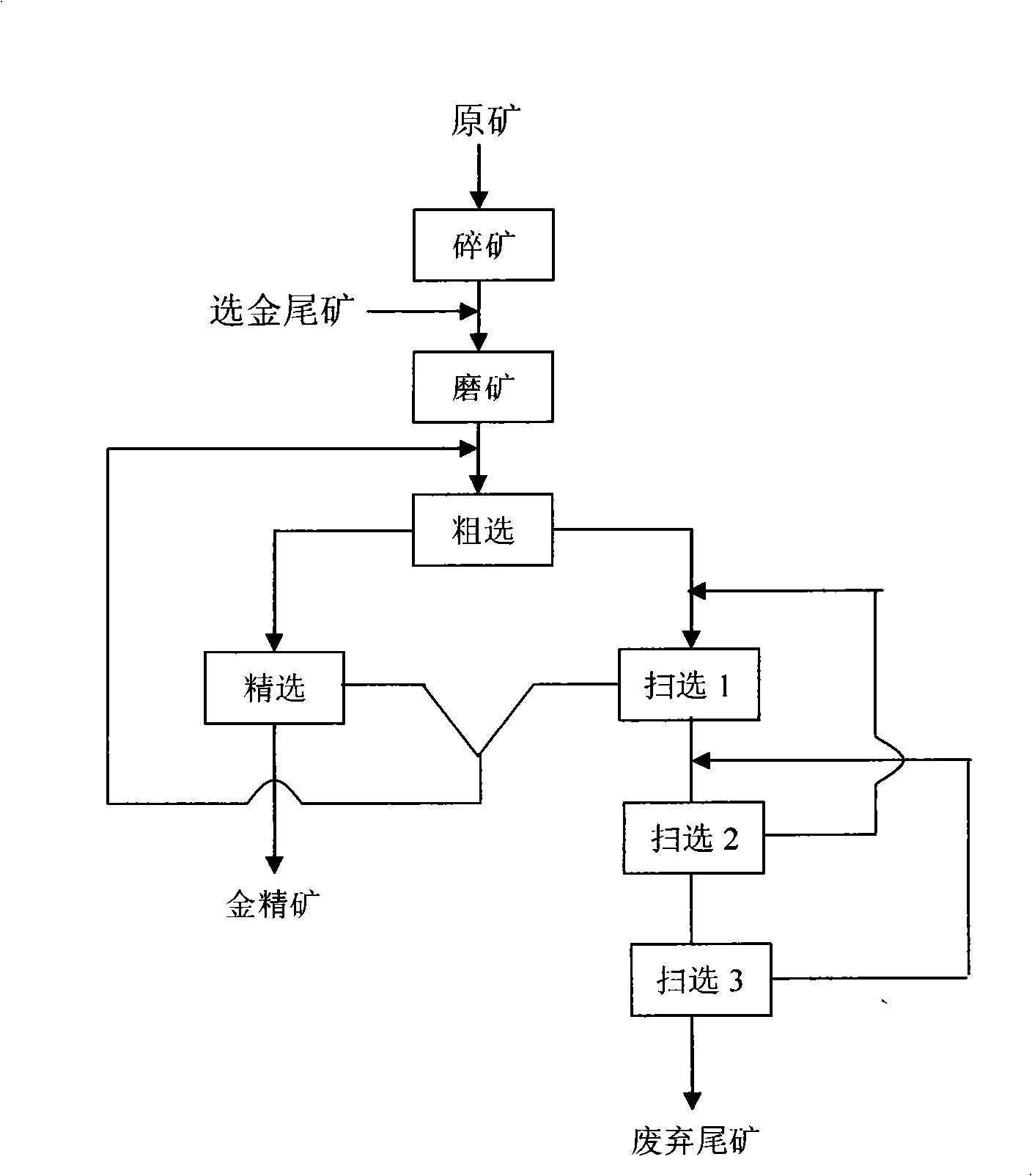

[0024] like figure 1 As shown, a beneficiation method for improving the recovery rate of gold in gold tailings uses raw ore as a carrier to connect the gold beneficiation tailings and apply a beneficiation agent, including the following sequential process steps:

[0025] a. Crushing, crushing the original ore;

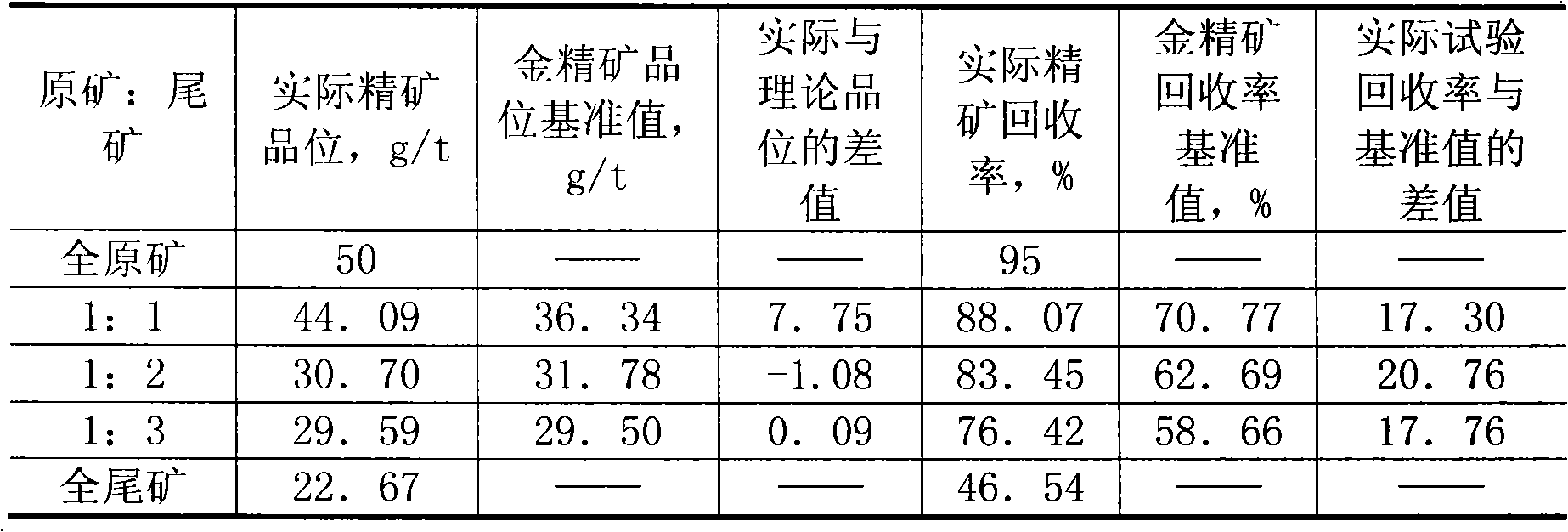

[0026] b. Grinding, adding the gold dressing tailings to the crushed raw ore at a ratio of 1:1 to 3 of the raw ore and the gold dressing tailings for grinding, and grinding to -0.074mm, 60 to 76% fineness;

[0027] c. Rough selection, adding 20~100g / t of butyl xanthate, 1~30g / t of butylammonium black medicine, and 5~20g / t of 2# oil to the ground mixed ore for rough selection;

[0028] d. Selecting, adding 20-100g / t of sodium silicate to the roughly selected coarse concentrate for selection, and selecting gold concentrate.

[0029] The beneficiation method for improving the gold recovery rate in the gold tailings of the present invention further comprises:

[0030] a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com