A kind of multifunctional coating for wine box outer packaging and preparation method thereof

An outer packaging, multi-functional technology, applied in the direction of paper coating, coating, no pigment coating, etc., can solve the problems of high storage risk, restricting the development of vacuum aluminized film-coated cardboard, low product quality, etc., and achieve process adaptation. Wide property, excellent adhesion fastness, good printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment relates to the preparation of a multifunctional coating for wine box outer packaging, comprising the following steps:

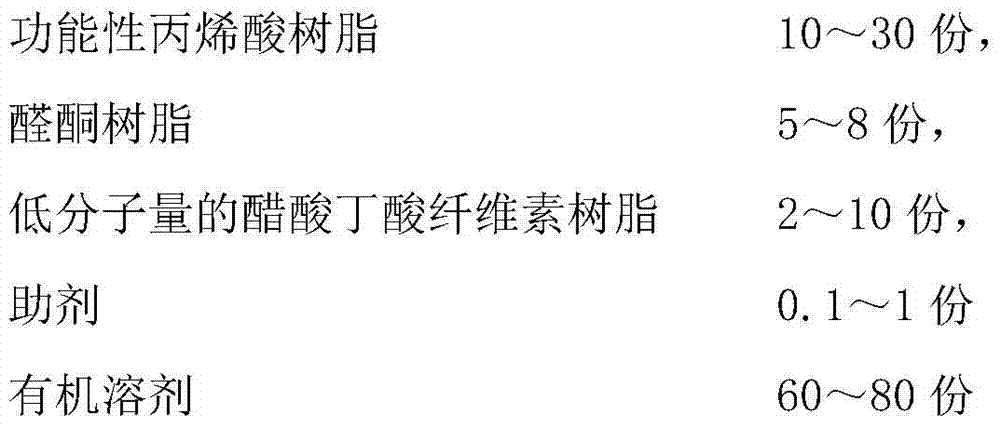

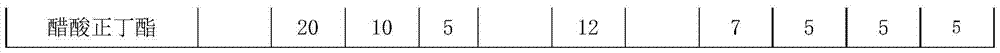

[0031] A. Prepare raw materials according to the components and parts by weight shown in Table 1:

[0032] B. Put the solvent in the reaction kettle, turn on the stirring device, stir at 80rpm for 30min, and heat up to 50°C;

[0033] C. Put the resin components (functional acrylate resin, aldehyde and ketone resin and low molecular weight cellulose acetate butyrate resin) into the reactor, control the stirring rate to 80rpm, and stir for 2h to fully dissolve the resin components;

[0034] D. When the resin component is completely dissolved, put the additives into the reaction kettle, control the stirring rate to 80rpm, stir for 20min until the additives are fully dispersed and evenly, and filter to obtain the final product.

[0035] In this embodiment, the functional polyacrylate resin is a hydroxyl-containing acrylic resin with a glas...

Embodiment 2

[0038] The preparation of the multifunctional coating for wine box outer packaging in this example is the same as in Example 1, except that the stirring time of the solvent in step B is 40 minutes, the temperature is raised to 60 ° C, and the stirring rate in step C is 200 rpm. The stirring time is 5 h; the stirring speed in step D is 120 rpm, and the stirring time is 30 min.

[0039] In this embodiment, the functional polyacrylate resin is a functional acrylic resin containing both hydroxyl and carboxyl groups, its glass transition temperature is 80°C, and its molecular weight is 35,000 to 52,000; the hydroxyl value of the aldehyde and ketone resin is 90 mgKOH / g, the glass transition temperature is 60°C, and the molecular weight is 600-1000; the glass transition temperature of the low molecular weight cellulose acetate butyrate resin is 80°C, and the molecular weight is 16,000-19,000.

[0040] In this embodiment 2, because the functional coating contains a high proportion of...

Embodiment 3

[0042] The preparation of the multifunctional coating for wine box outer packaging in this example is the same as in Example 1, the difference is that in step B, the stirring time of the solvent is 60min, and the temperature is raised to 70°C; in step C, the stirring rate is 250rpm, and the stirring The time is 6h; the stirring rate in step D is 150rpm, and the stirring time is 40min.

[0043] In this embodiment, the functional polyacrylate resin is a hydroxyl-containing acrylic resin with a glass transition temperature of 100°C and a molecular weight of 52,000 to 70,000; the hydroxyl value of the aldehyde and ketone resin is 250 mgKOH / g, and the glass transition temperature The temperature is 30°C, and the molecular weight is 1000-1600; the glass transition temperature of the low molecular weight cellulose acetate butyrate resin is 140°C, and the molecular weight is 19,000-23,000.

[0044] In Example 3, the functional coating contains more functional acrylic resins, combined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com