A precision control method for electron beam welding deformation of rotor parts

A technology of electron beam welding and precision control, which is applied in the direction of electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of low bolt connection process strength, poor part manufacturing compliance, and poor part adaptability, so as to improve design and manufacturing compliance. High performance, improved service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

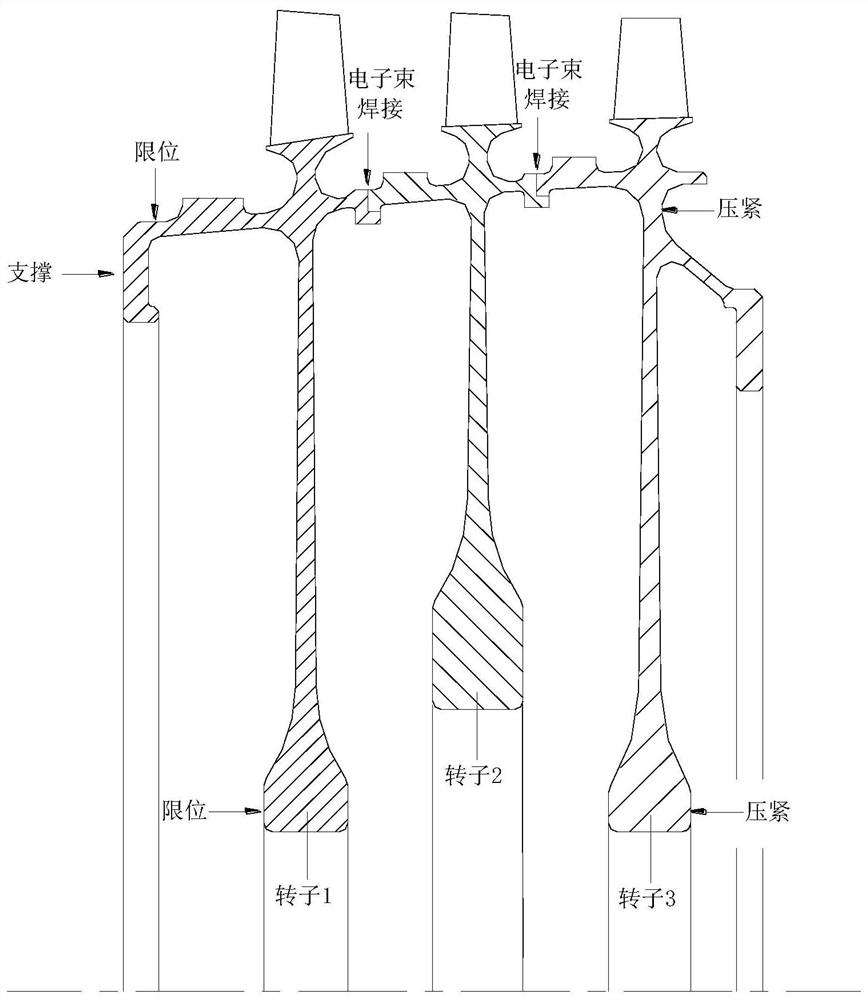

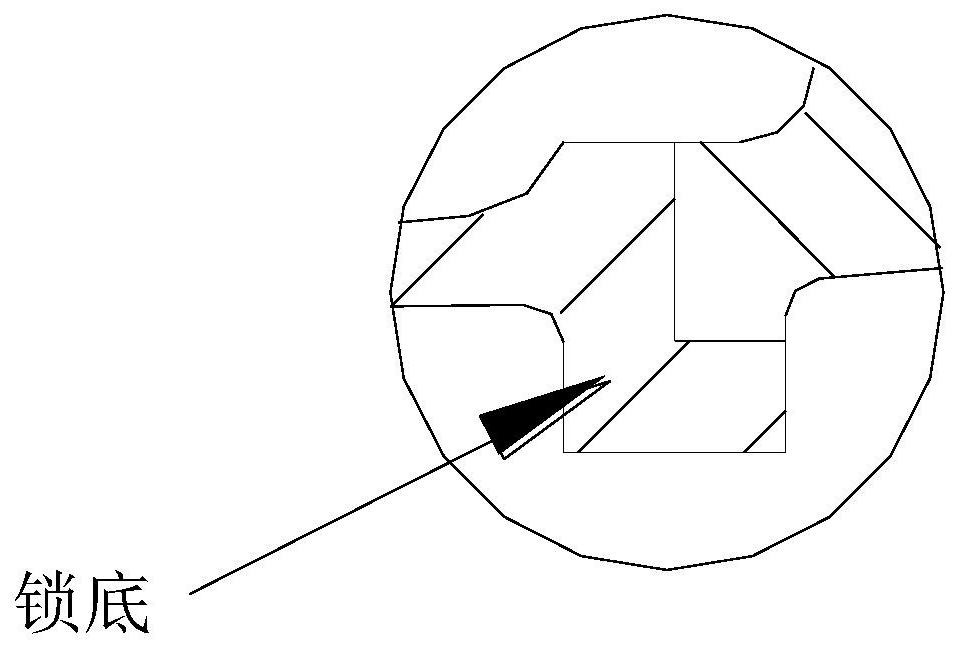

[0039] A precise control method for electron beam welding deformation of rotor parts. According to the structure of rotor parts and the characteristics of electron beam welding process, the causes of welding deformation are analyzed, and measures are taken from the following aspects to control welding deformation: 1) in the guarantee Under the premise of weld performance, adjust the pre-weld state of rotor parts from solid solution state to aging state, strengthen materials, improve the rigidity of rotor parts, and reduce welding deformation; 2) thin-walled cantilever for rotor parts structure, with the characteristics of large axial displacement after welding, the design of tooling with functions such as positioning, rigid limit and radial plate compression can reduce the axial displacement of the radial plate; The assembly and positioning ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com