Method for extracting vanadic anhydride from stone coal

A technology of vanadium pentoxide and stone coal vanadium, applied in vanadium oxide and other directions, can solve the problems of high energy consumption, environmental pollution, large land occupation, etc., and achieve high comprehensive recovery rate, wide process adaptability and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

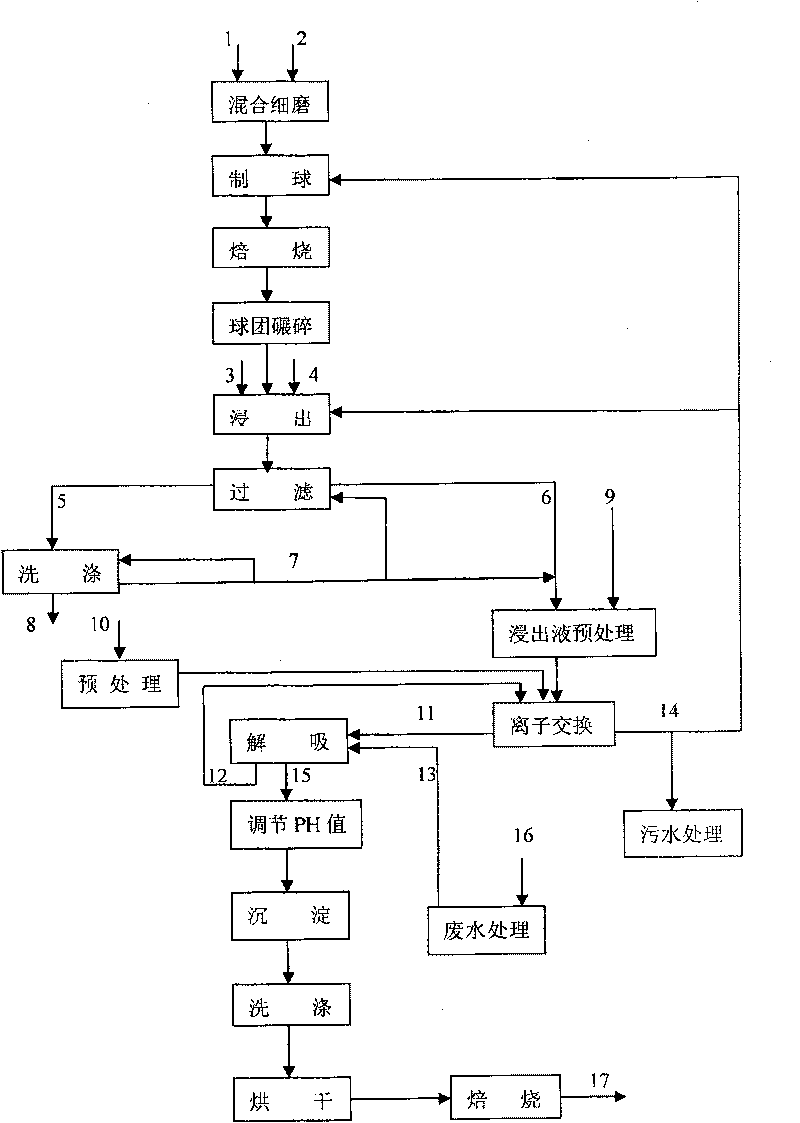

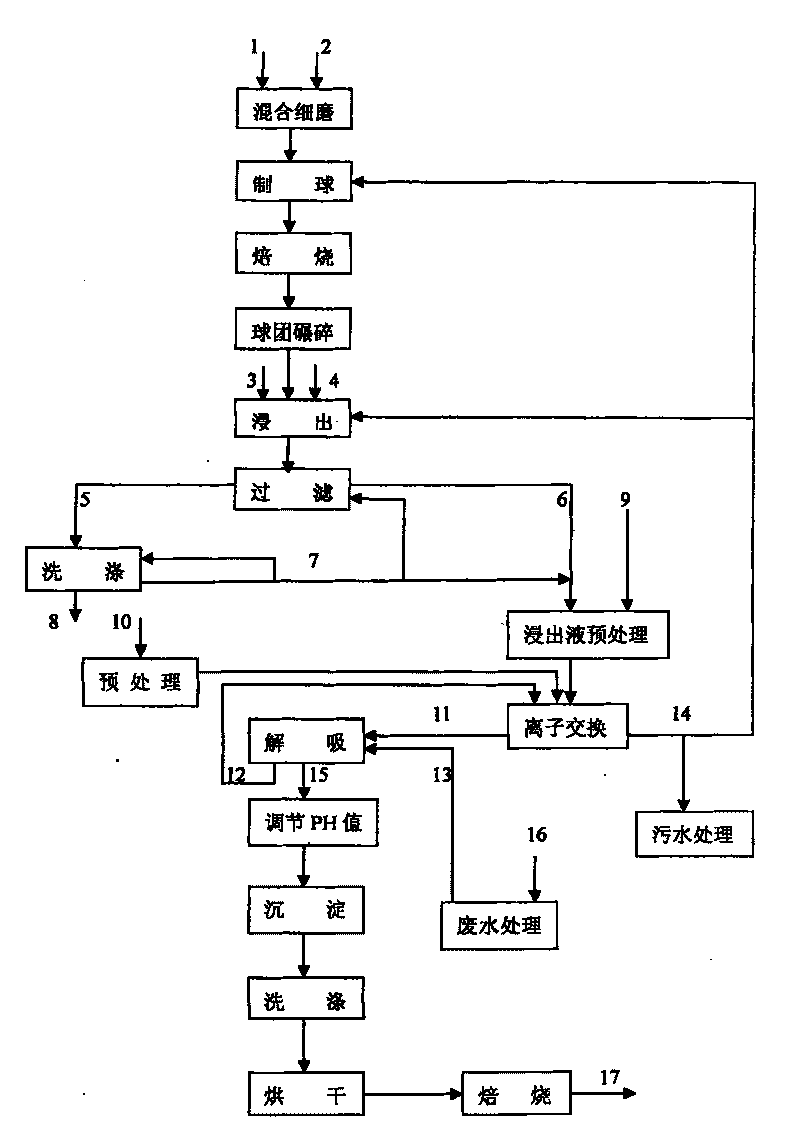

[0037] Such as figure 1 Shown, a kind of method of extracting vanadium pentoxide from stone coal comprises following process step and condition:

[0038] a. mixing and fine grinding, adding limestone ore 2 with a weight ratio of 5 to 12% to stone coal vanadium ore 1 and mixing, coarse crushing first, and then fine grinding to 50 to 150 mesh;

[0039] b. Ball making, the diameter of the ball is controlled at 6-12mm;

[0040] c. Roasting, after drying the prepared balls, put them into the converter, decarburize in the first stage at 600-800°C for 1-4 hours, and heat in the second stage at 800-1100°C for roasting and oxidation for 2-6 hours;

[0041] d. The pellets are crushed, and the roasted pellets are crushed;

[0042] e. Leaching, crush the pellets and pour them into a stirring tank, add water 3 and sulfuric acid 4 with a weight ratio of 1 to 8%, and leaching at room temperature for 2 to 7 hours;

[0043] f. Filtration, the pulp is filtered, and the leaching residue 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com