Flux-cored wire and method capable of enhancing copper/steel interface bonding strength

A technology of interfacial bonding strength and flux-cored wire, applied in the direction of welding/welding/cutting items, welding media, welding equipment, etc., can solve problems such as joint failure, poor quality of welded joints, and great differences in physical properties, etc., to achieve fine Surface grain, grain refinement, and effect of improving residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

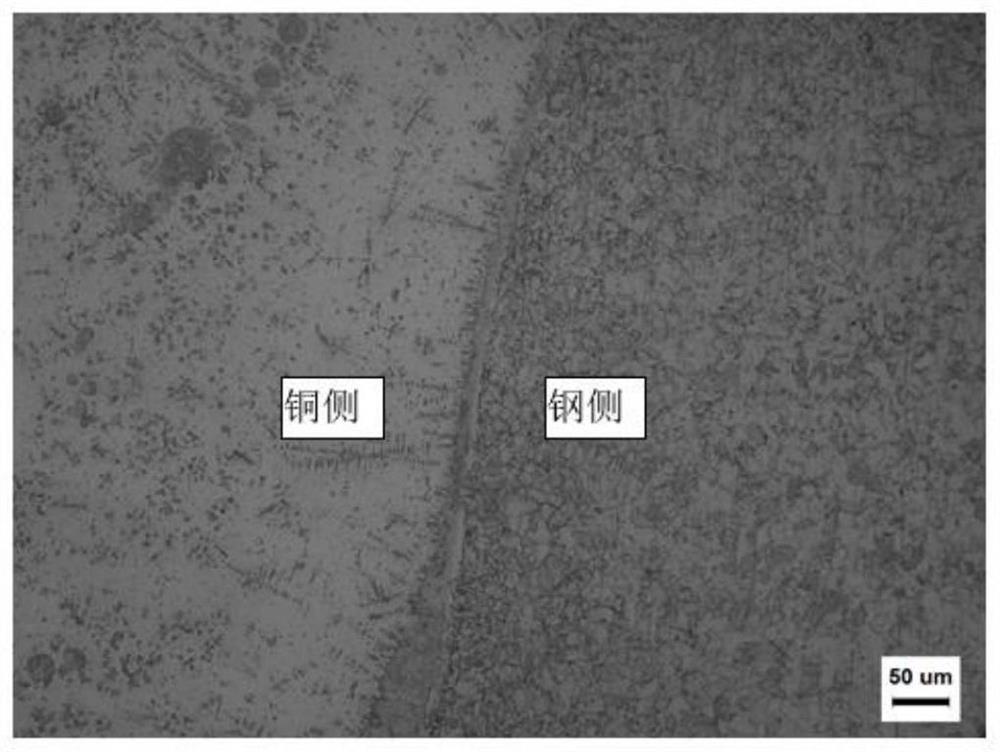

Image

Examples

Embodiment 1

[0041] Step 1, respectively weigh the following powders: Mg powder: 10g; Ti powder: 10g; Co powder: 5g; Ni powder: 20g; Si powder: 1g; Mn powder: 1g; Cu powder: 53g. The sum of the mass percentages of the above components is 100%.

[0042] Step 2: Use the powder weighed in step 1 as the core, fill the core into the U-shaped groove, use the pure copper strip as the welding wire skin, and use the aperture Complete the first drawing process for the 2.3mm diameter reducing die, and finally reduce the diameter of the flux-cored welding wire to 1.6mm through the reducing die continuously; use the wire drawing machine to make the required welding wire, and store the welding wire in the incubator after the preparation is completed ; The filling rate of the flux core powder in the flux cored wire is 25wt.%.

[0043] Step 3: TIG welding is used to weld T2 copper and Q345A steel plates, and the filler metal uses the flux-cored wire prepared in step 2; welding parameters are, welding vo...

Embodiment 2

[0048] Step 1, respectively weigh the following powders: Mg powder: 10g; Ti powder: 15g; Co powder: 7g; Ni powder: 20g; Si powder: 1g; Mn powder: 1g; Cu powder: 46g. The sum of the mass percentages of the above components is 100%.

[0049]Step 2: Use the powder weighed in step 1 as the core, fill the core into the U-shaped groove, use the pure copper strip as the welding wire skin, and use the aperture Complete the first drawing process for the 2.3mm diameter reducing die, and finally reduce the diameter of the flux-cored welding wire to 1.6mm through the reducing die continuously; use the wire drawing machine to make the required welding wire, and store the welding wire in the incubator after the preparation is completed ; The filling rate of the flux core powder in the flux cored wire is 32wt.%.

[0050] Step 3: TIG welding is used to weld T2 copper and Q345A steel plates, and the filler metal uses the flux-cored wire prepared in step 2; welding parameters are, welding vol...

Embodiment 3

[0055] Step 1, respectively weigh the following powders: Mg powder: 15g; Ti powder: 10g; Co powder: 5g; Ni powder: 20g; Si powder: 1g; Mn powder: 1g; Cu powder: 48g. The sum of the mass percentages of the above components is 100%.

[0056] Step 2: Use the powder weighed in step 1 as the core, fill the core into the U-shaped groove, use the pure copper strip as the welding wire skin, and use the aperture Complete the first drawing process for the 2.3mm diameter reducing die, and finally reduce the diameter of the flux-cored welding wire to 1.6mm through the reducing die continuously; use the wire drawing machine to make the required welding wire, and store the welding wire in the incubator after the preparation is completed ; The filling rate of the flux core powder in the flux cored wire is 26wt.%.

[0057] Step 3: TIG welding is used to weld T2 copper and Q345A steel plates, and the filler metal uses the flux-cored wire prepared in step 2; welding parameters are, welding vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com