Method for removing aluminum from nickel-cobalt solution

A solution, nickel-cobalt technology, applied in the field of aluminum removal from nickel-cobalt solution, can solve the problems of difficult filtration of liquid after aluminum removal, difficult filtration, high reaction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

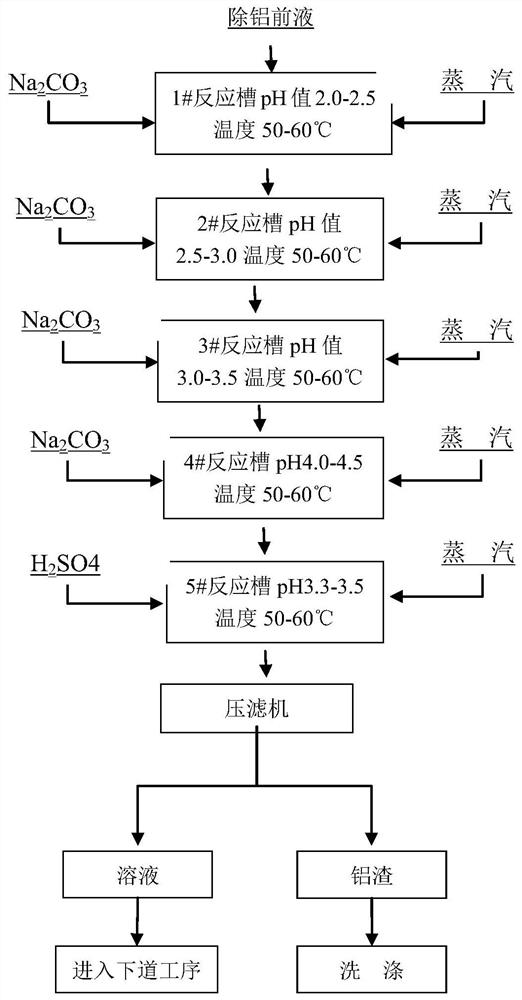

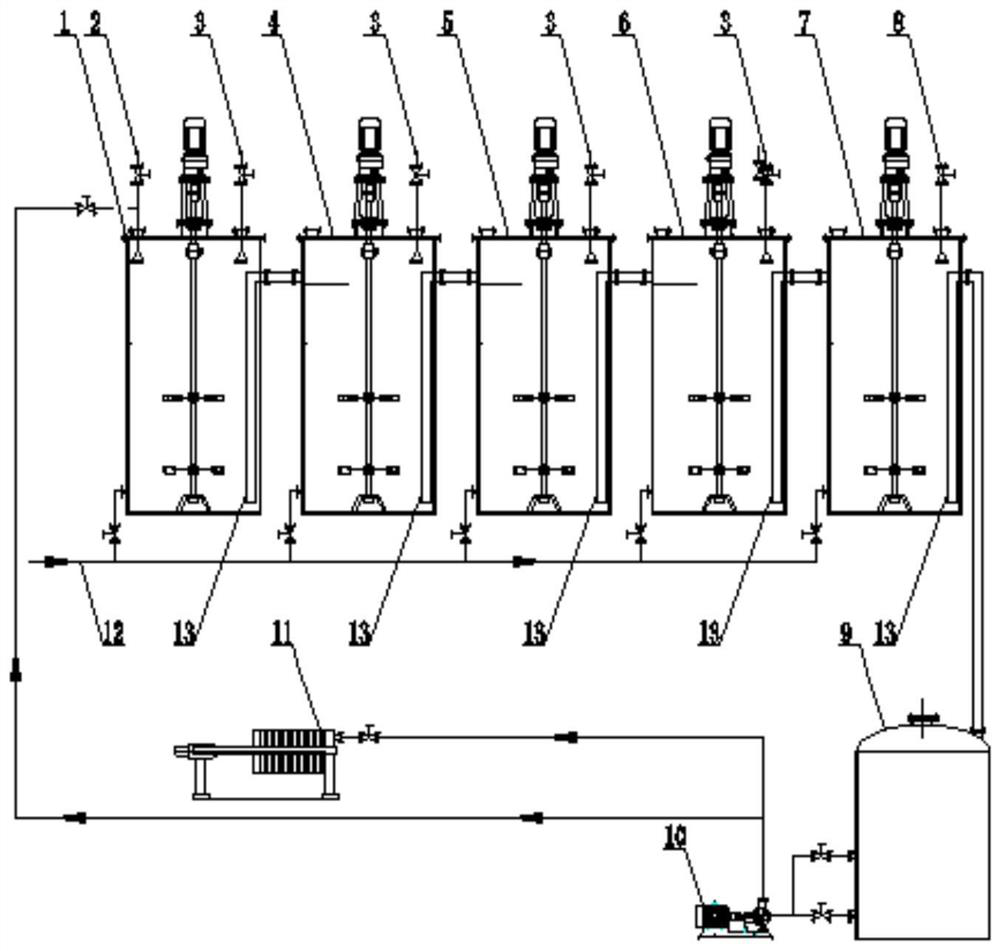

[0038] equipment such as figure 2 shown.

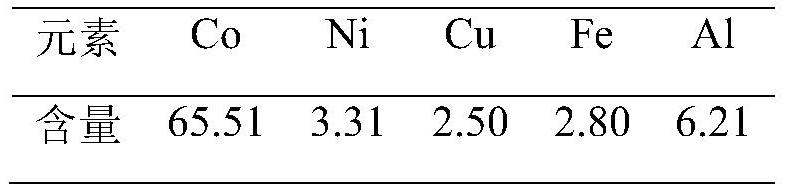

[0039] (1) Add 1 to the solution before removing aluminum, and the element content in the solution (g / L):

[0040]

[0041] 1 Volume 25m 3 , the solution is added by spraying through 2, and the volume added is 12m 3 / h, when the solution has not passed the paddle, turn on the stirring paddle, the speed of the stirring paddle is 300r / min, adopt the propulsion type paddle, add steam through 12, use direct steam to heat, control the reaction temperature of the solution at 50°C, and add Na through 3 2 CO 3 , control the pH value between 2.0-2.5, the filling time of 1 solution is 1 hour and 40 minutes, and enter 4 through 13 after 1 is filled. 1 should add aluminum vanadium seed crystals in the first reaction, and the addition amount is about 100Kg , during the continuous reaction process, add 7 treated solution, the volume is 2m 3 / h.

[0042] (2) 4 volumes 25m 3 , the solution reaction temperature is 50°C, and Na is added thro...

Embodiment 2

[0052] equipment such as figure 2 shown.

[0053] (1) Add 1 to the solution before removing aluminum, and the element content in the solution (g / L):

[0054]

[0055] 1 Volume 25m 3 , the solution is added by spraying through 2, and the volume added is 15m 3 / h, when the solution has not passed the paddle, turn on the stirring paddle, the speed of the stirring paddle is 50r / min, adopt the push type paddle, add steam through 12, use direct steam to heat, control the reaction temperature of the solution at 60°C, and add Na through 3 2 CO 3 , control the pH value between 2.0-2.5, the time for 1 solution to fill is 40 minutes, after 1 is filled, enter 4 through 13. In the first reaction, aluminum vanadium seeds should be added, the amount added is about 100Kg, continuous During the reaction, add 7 treated solution, the volume is 3m 3 / h.

[0056] (2) 4 volumes 25m 3 , the reaction temperature of the solution is 60°C, and Na is added through 3 2 CO 3 , control the pH v...

Embodiment 3

[0066] (1) Add 1 to the solution before removing aluminum, and the element content in the solution (g / L):

[0067]

[0068] 1 Volume 25m 3 , the solution is added by spraying through 2, and the volume added is 13m 3 / h, when the solution has not passed the paddle, turn on the stirring paddle, the speed of the stirring paddle is 100r / min, use the propulsion type paddle, add steam through 12, use direct steam to heat, control the reaction temperature of the solution at 55°C, and add Na through 3 2 CO 3 , control the pH value between 2.0-2.5, the filling time of 1 solution is 1 hour and 40 minutes, and enter 4 through 13 after 1 is filled. 1 should add aluminum vanadium seed crystals in the first reaction, and the addition amount is about 100Kg , during the continuous reaction process, add 7 treated solution, the volume is 2.5m 3 / h.

[0069] (2) 4 volumes 25m 3 , the reaction temperature of the solution is 55°C, and Na is added through 3 2 CO 3 , control the pH value b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com