Furniture screen printing internal engraving 3D (three-dimensional) paint process

A screen printing and furniture technology, applied in polyurea/polyurethane coatings, special surfaces, devices for coating liquids on surfaces, etc., can solve the problems of lack of literature and achieve high saturation, wide adaptability, and thick ink colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

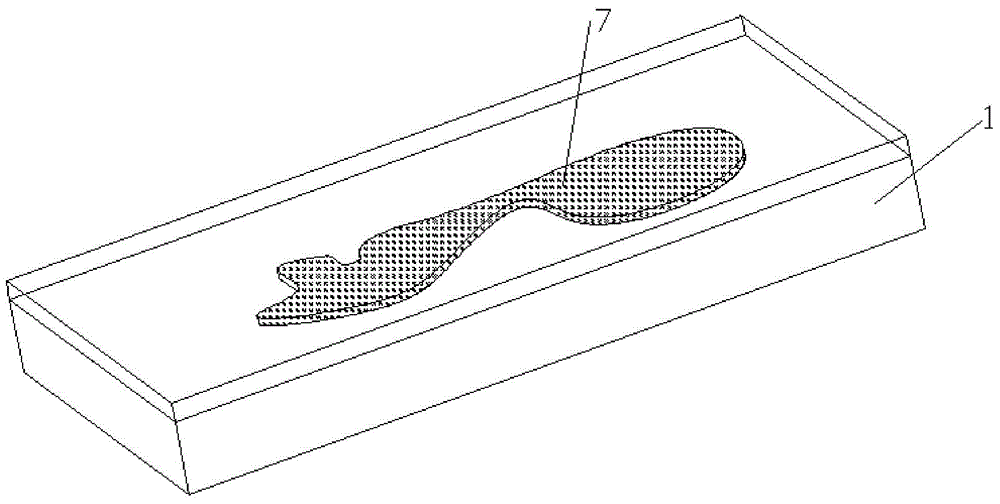

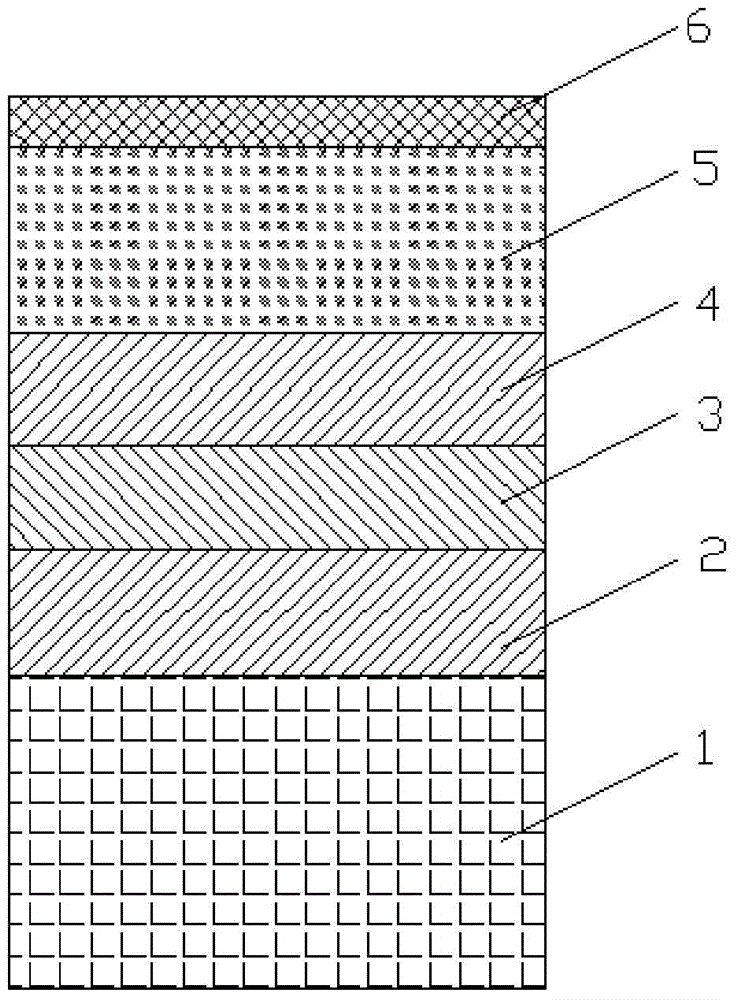

[0039] Example 1: see Figure 1 ~ Figure 2 , The three-dimensional paint process for furniture silk screen internal carving provided in this embodiment includes the following steps:

[0040] (1) Soil-filling: After the surface of furniture product 1 to be processed is thickened with a large-scale fixed-thickness sanding machine, a layer of putty is applied to the outer surface of the furniture product 1 and then polished with coarse sandpaper to obtain a base layer 2 ;

[0041] (2) Spraying and polishing the nano-sealing primer: evenly sweep the nano-primer on the surface of the product 1. After the nano-primer is air-dried for 42 to 52 hours, polish and sand with coarse sandpaper to obtain the sealing primer layer 3. ;

[0042] (3) Spraying PE primer: spray the PE primer evenly on the sealing primer layer 3 in two to four times. After the PE primer is air-dried for 30 to 40 hours, sand and sand the surface with sandpaper to obtain the upper primer Lacquer layer 4;

[0043] (4) Thr...

Embodiment 2

[0061] Embodiment 2: The basic steps of this embodiment are the same as those of embodiment 1, except that the preparation method of the PU topcoat further includes the following steps:

[0062] (51) In a four-necked flask equipped with a stirrer, a thermometer, a condenser and a dropping funnel, measure each component in the following molar ratio, toluene diisocyanate 2: polyether glycol 3:1, 4-butane Diol 3: 2,2-Dimethylolpropionic acid 3: Epoxy resin 4: Hydroxypropyl acrylate 2: Triethylamine 1: Nano glass beads 3: Pearl powder 1.5, the toluene diisocyanate and polyether two The alcohol is added to the reaction system, the catalyst dibutyl tin dilaurate is dropped, the reaction is first at 40°C for 30 minutes, then the temperature is raised to 80°C, and the reaction is held at a constant temperature for 1.5 hours;

[0063] (52) Cool down to 70°C, weigh 1,4-butanediol according to step (51), slowly add small molecule chain extender 1,4-butanediol with a dropping funnel, and react...

Embodiment 3

[0069] Embodiment 3: The basic steps of this embodiment are the same as those of embodiment 1, except that the preparation method of the PU topcoat further includes the following steps:

[0070] (51) In a four-necked flask equipped with a stirrer, a thermometer, a condenser and a dropping funnel, measure the components in the following molar ratio, toluene diisocyanate 10: polyether glycol 6:1, 4-butane Diol 4: 2,2-Dimethylolpropionic acid 4: Epoxy resin 3: Hydroxypropyl acrylate 3: Triethylamine 1.5: Nano glass beads 4: Pearl powder 2. Combine toluene diisocyanate with polyether two The alcohol is added to the reaction system, the catalyst dibutyltin dilaurate is dropped, the reaction is first at 40°C for 30 minutes, then the temperature is raised to 80°C, and the reaction is constant for 1.5h-2h;

[0071] (52) Cool down to 75°C, weigh 1,4-butanediol according to step (51), slowly add small molecule chain extender 1,4-butanediol with a dropping funnel, and react at this temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com