Novel exposure blueprinting method for screen printing plate

A new type of screen printing technology, applied in printing plate preparation, printing, etc., can solve problems such as unevenness of the photosensitive film surface, and achieve the effect of clear and accurate graphic size and flat and smooth screen graphic surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0030] A kind of novel screen printing method of the present invention, comprises the following steps,

[0031] S1: Make PET film: cut a piece of PET film with the same size as the screen area, then roll it up and put it in the scraper for later use;

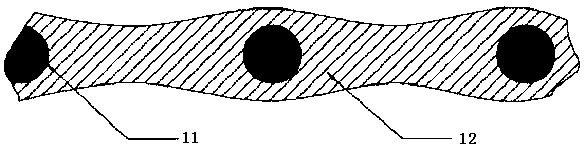

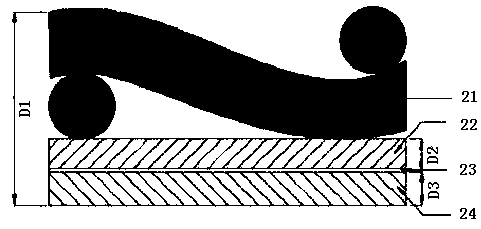

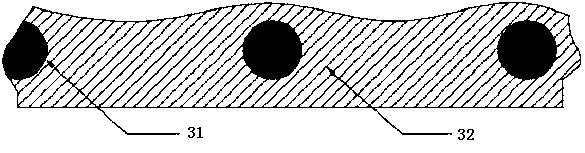

[0032] S2: Pre-coat the photosensitive adhesive of component a on the base of the cleaned stainless steel mesh and dry it, and when scraping the printing surface of the substrate of the stainless steel mesh, reserve 1um for the total thickness, and then coat the photosensitive adhesive of component b for two times. Road, while slowly coating the PET film described in step S1 from bottom to top to form a three-layer structure (such as figure 2 shown), and then enter the drying process. When it is close to drying, tear off the PET film and continue drying until it is not sticky;

[0033] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com