Removal structure for central shaft of sanding belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

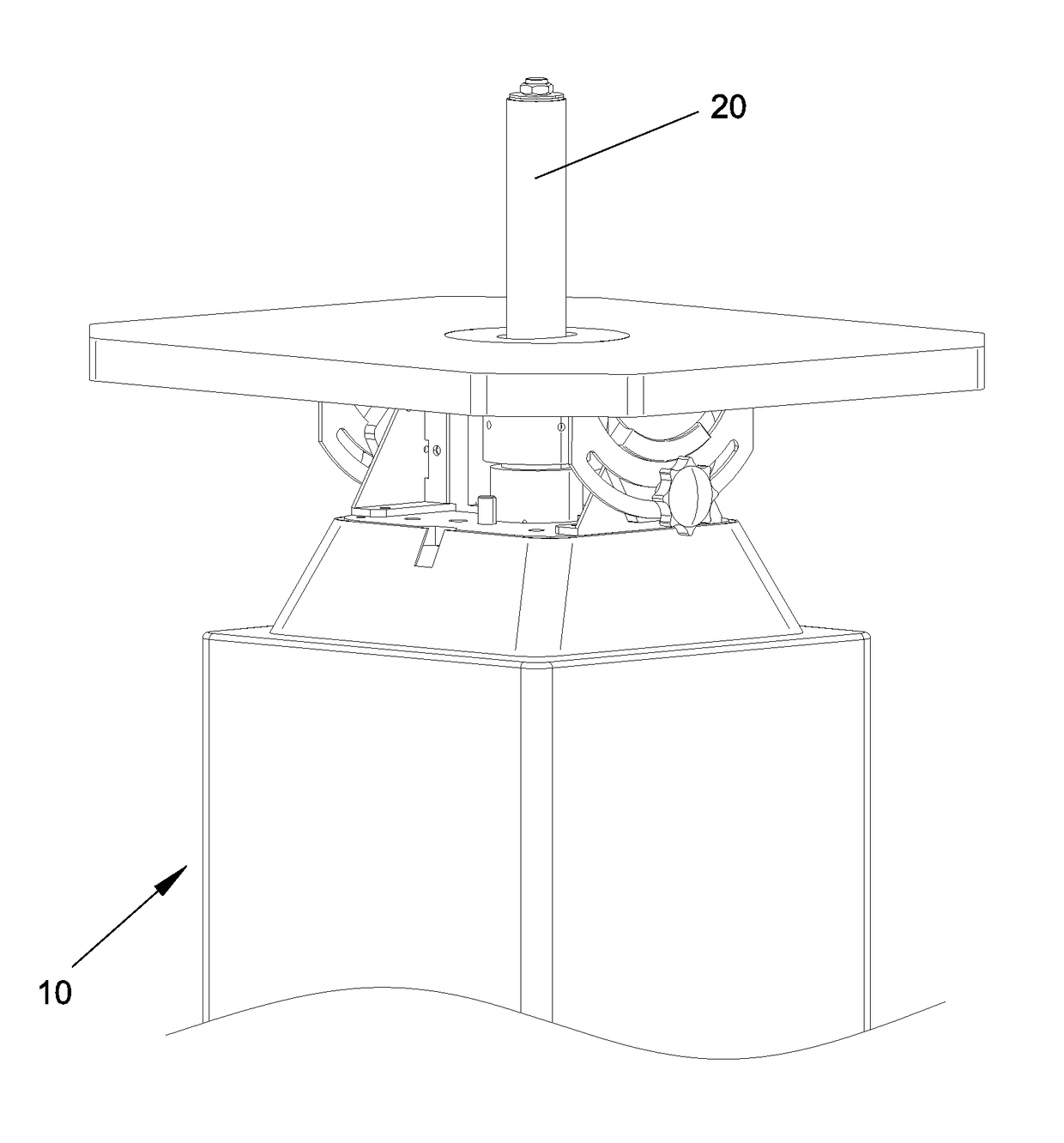

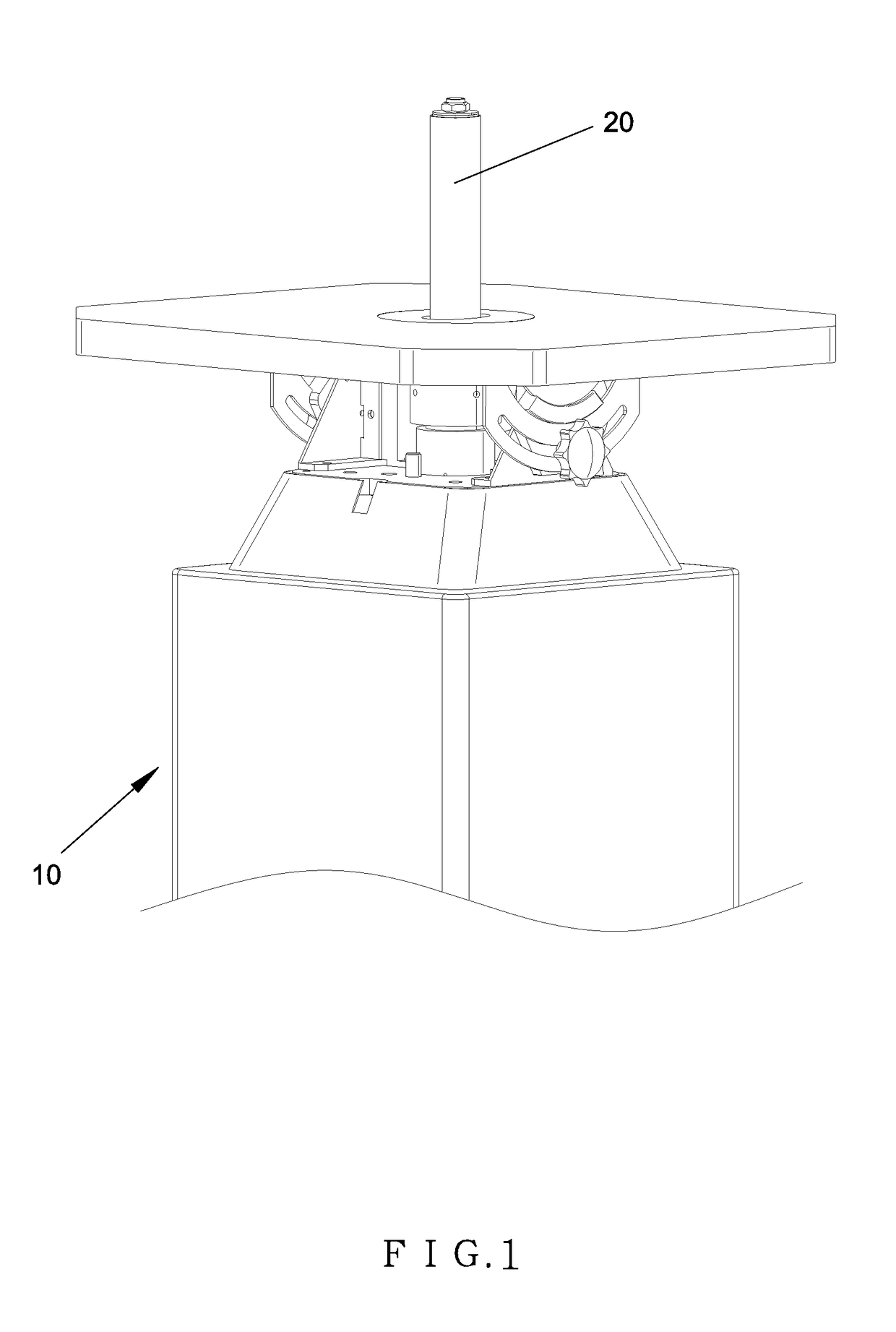

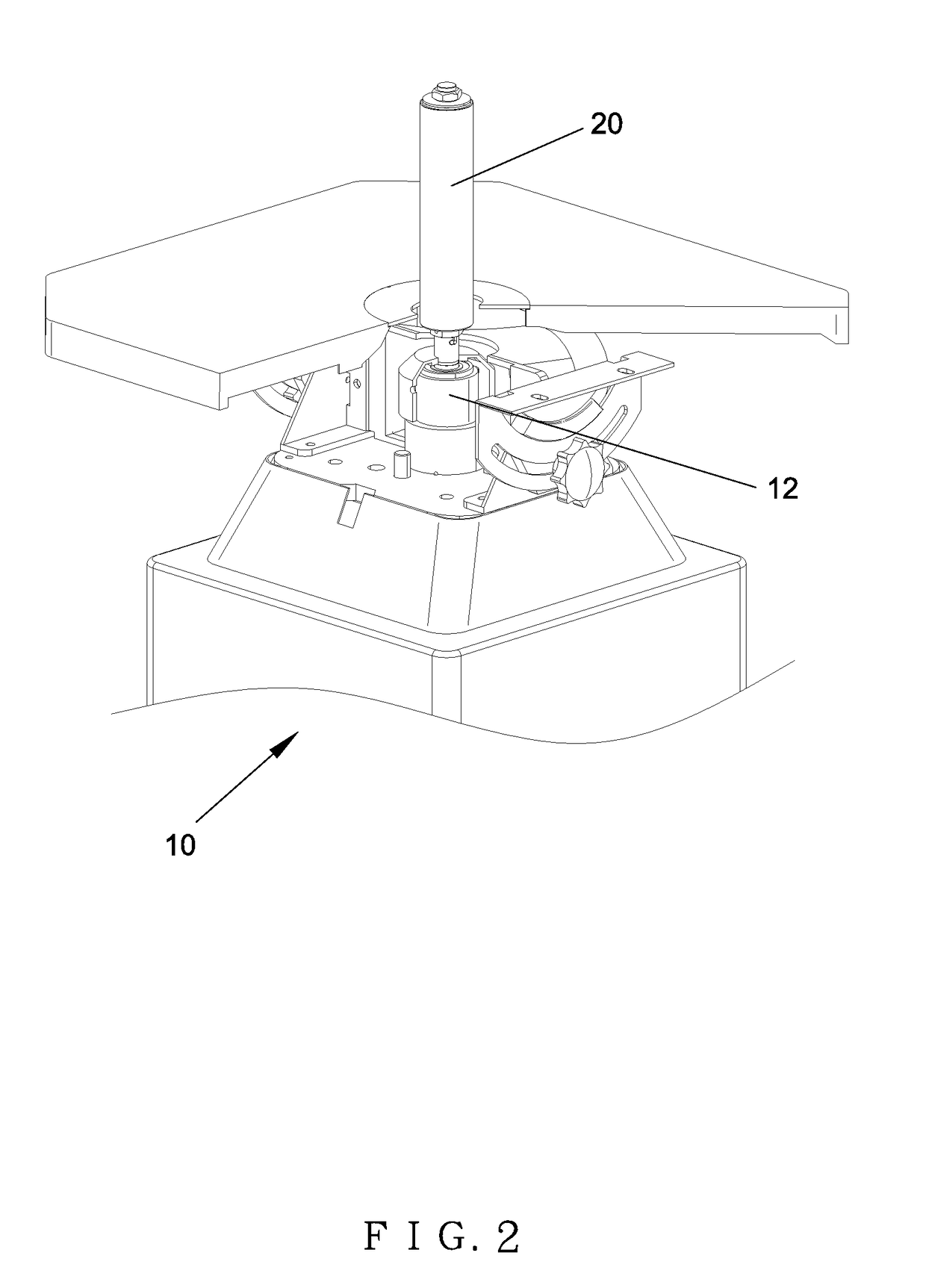

[0016]With reference to FIGS. 1 to 3, a removal structure for a central shaft of a sanding belt according to a preferred embodiment of the present invention is fixed on a grinding machine 10, and the grinding machine 10 comprises: a driver 11, a driving shaft 12 mounted on a top of the driver 11, a fitting sleeve 13 extending outwardly from a central position of the driving shaft 12, a conical groove 15 defined in the fitting sleeve 13, and at least one L-shaped notch 14 formed on a peripheral wall of the fitting sleeve 13 in an array arrangement. A connection column 20 is fitted with the driving shaft 12 and includes a central shaft 21 formed in a cone shape so as to correspond to the conical groove 15 of the fitting sleeve 13, wherein the central shaft 21 has at least one locking post 22, a number of which is equal to that of the at least one L-shaped notch 14.

[0017]Referring to FIGS. 3 to 5, the at least one locking post 22 of the central shaft 21 is inserted into the conical gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com