Realization method for detection controller for valve position adjustment abnormity of industrial pulverized coal boiler

A pulverized coal boiler and controller technology, applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems that the furnace safety monitoring system has not received widespread attention, combustion adequacy and economic adverse effects, explosions, etc., to achieve technological Wide adaptability, strong anti-interference ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

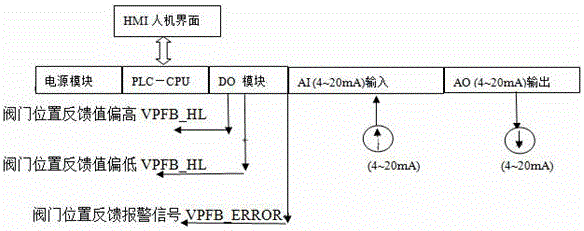

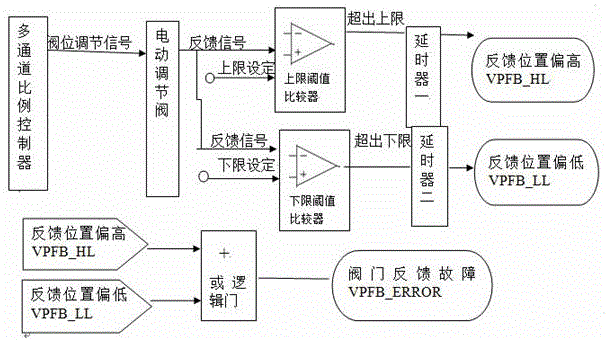

[0020] Such as figure 1 , as shown in 2, an implementation method of an industrial pulverized coal boiler valve position adjustment abnormality detection controller in this embodiment, the detection controller includes a multi-channel proportional controller, an electric regulating valve, an upper limit threshold comparator, a lower limit threshold Comparator, delayer 1, delayer 2, or logic gate, PLC / DCS controller, DO module, AI input module and AO output module, in the process of pulverized coal combustion, when adjusting the control value and feedback value of the valve When the error value exceeds the maximum allowable upper limit and lower limit, the timing alarm control is started through the threshold comparator, and the time elapsed is the error overrun time. If the error over-limit time exceeds the preset normal input response time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com