Combined synthetic method for liquid hydrocarbon

A liquid hydrocarbon, combined technology, applied in the field of two-stage Fischer-Tropsch synthesis, can solve the problems of difficult reaction heat release, low CO utilization rate, high catalyst deactivation rate, and achieve strong anti-sulfur poisoning performance, water-gas shift Powerful, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

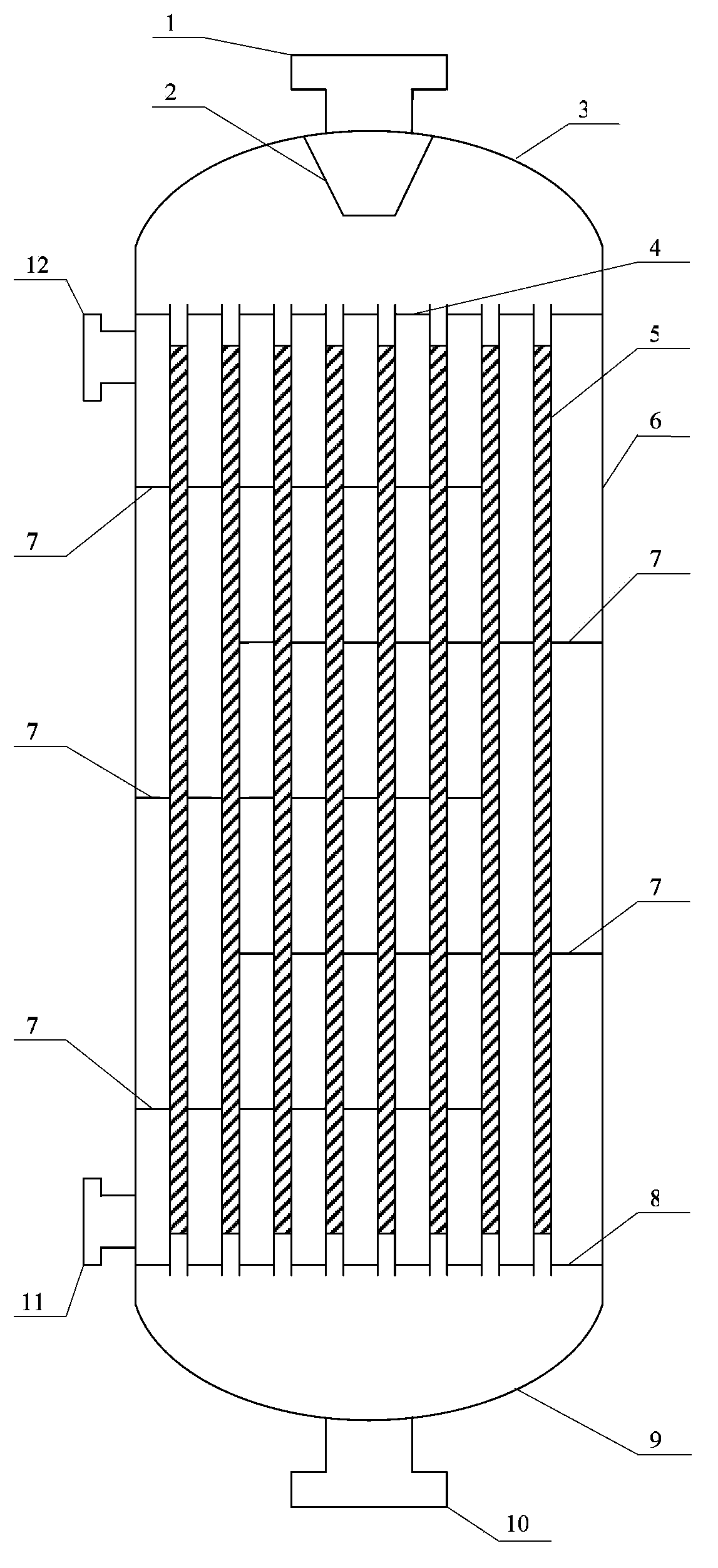

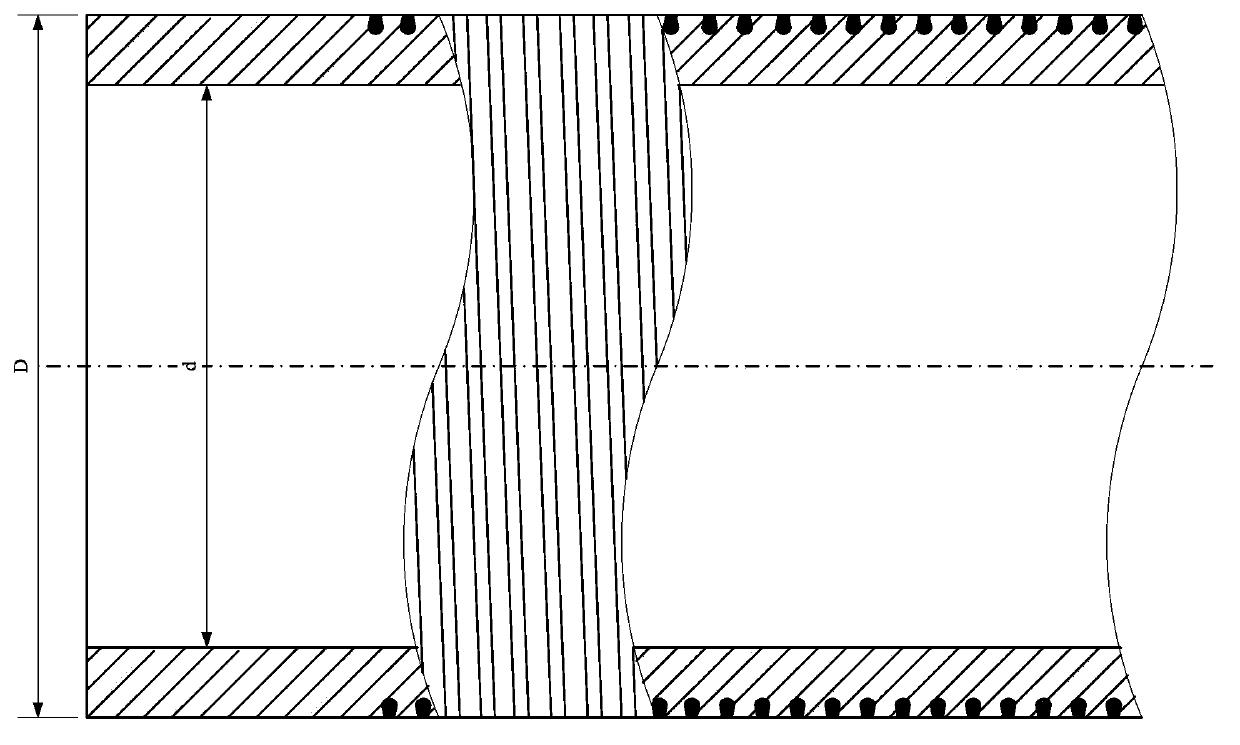

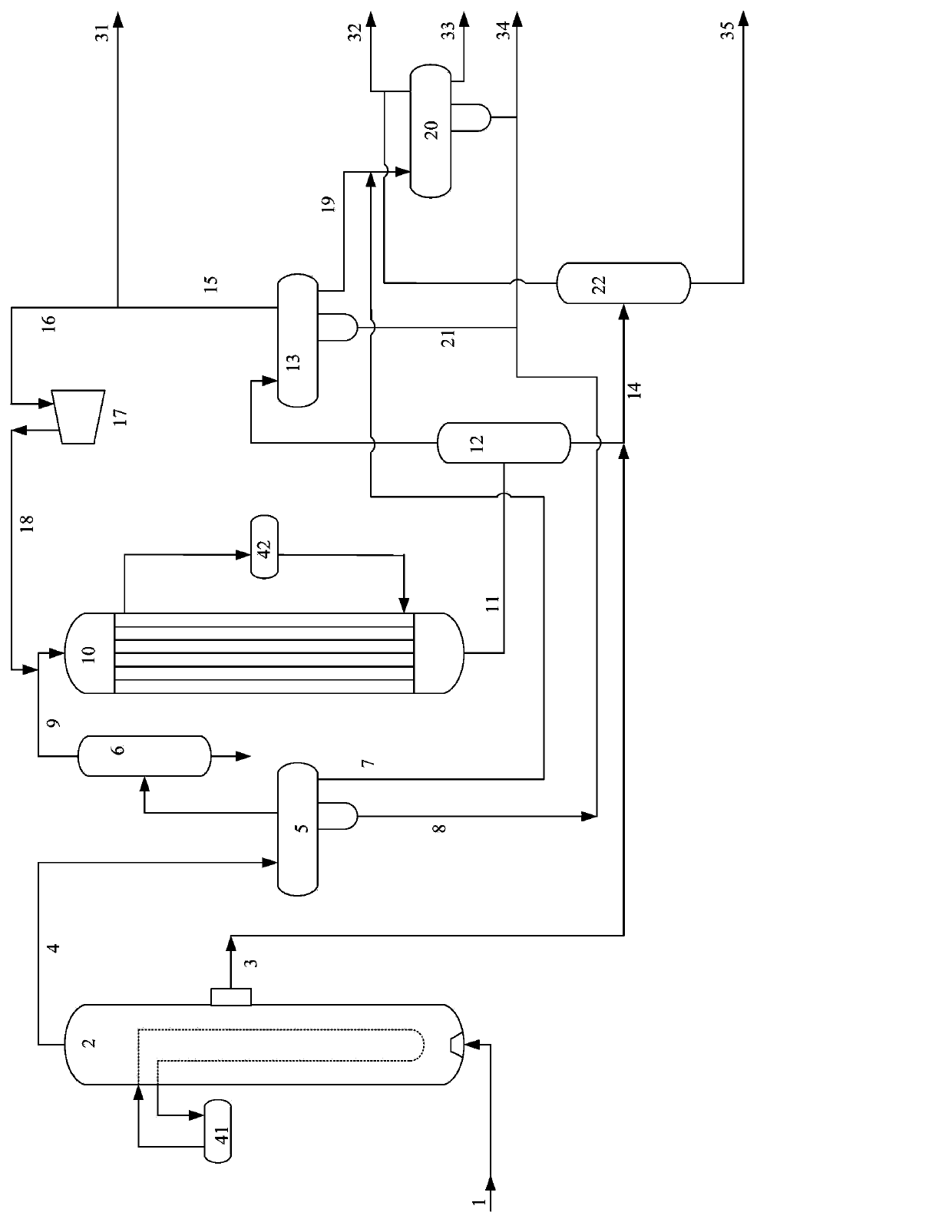

[0043] In this embodiment, the Fischer-Tropsch synthesis reaction is carried out by using the process and equipment shown in the accompanying drawings. The slurry bed reactor adopts the slurry external circulation separation form. There are 300 reaction tubes in the tubular fixed bed synthesis reactor. The reaction tubes are made of austenitic stainless steel pipes with an outer diameter of 38 mm and a wall thickness of 3 mm. The outer surface is cold-processed to form a groove structure. Each meter of tube length contains 500 grooves. , the groove depth is 1.2mm, the average groove width is 0.6mm, and the helix angle is 4°.

[0044] The first stage reactor adopts iron-based Fischer-Tropsch synthesis catalyst, which is prepared by precipitation method, and the main components are Fe, Cu, alkaline earth metals, K and SiO 2 , the catalyst weight composition is 100Fe:5Cu:5K:25SiO 2 . The preparation process of the catalyst used is as follows: mix a certain proportion of ferric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com