Electrical heating automobile laminated glass with a shunt bus

A technology of laminated glass and electric heating, applied in windshields, transparent/reflective heating devices, vehicle parts, etc., can solve the problems of different current travel paths, unreasonable connector settings, unreasonable lead layout, etc., to eliminate hot spots effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

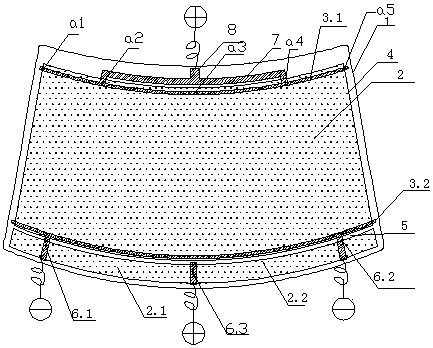

[0058] as the picture shows, figure 1 A piece of front windshield glass 1 is given in the figure, which has an electrothermal film layer 2 that prevents oxidation on the periphery and forms a film removal boundary 4, and a wiper rest position heating zone 2.1, 2.2 for auxiliary heating; on the film layer 2, there are two Roughly parallel upper busbar 3.1 and lower busbar 3.2, the first auxiliary busbar 6.1 and the second auxiliary busbar 6.2 connected to the lower busbar 3.2 are arranged in the heating area of the wiper static position, and the third auxiliary busbar 6.3 not connected to the lower busbar is arranged at the same time , the second bus bar is in contact with the film layer to generate electrical connection; the main visual heating area is formed between the two upper and lower bus bars; the auxiliary bus bars 6.1 and 6.3 drawn from the bus bar form the heating area of the wiper at rest; the auxiliary bus bars 6.2, 6.3 drawn from the bus bar 6.3 Constitute the...

Embodiment 2

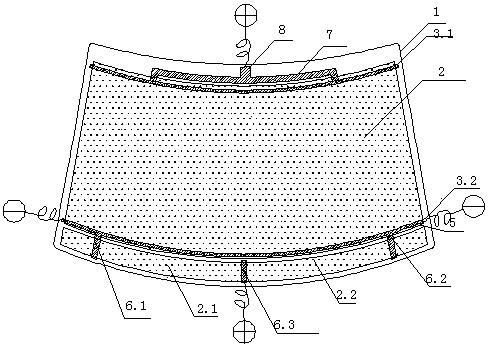

[0065] figure 2 gives something like figure 1 If the middle joints of the heating zone in the static position of the wiper are not all on the side of the big end, the first auxiliary busbar 6.1 and the second auxiliary busbar 6.2 do not need to be widened. Others are with embodiment 1.

Embodiment 3

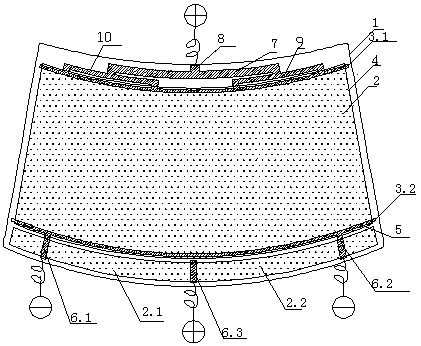

[0067] image 3 gives something like figure 1 When the glass is very wide, the effect of uniform heating cannot be achieved through one shunt bus, so the second shunt bus and the third shunt bus can be constructed, and so on. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com