Preparation process for stainless steel wire

A technology of stainless steel wire and preparation process, which is applied in the field of stainless steel wire preparation technology, can solve the problems of unfavorable enterprise capacity expansion, occupying a large area, and increasing transportation costs, so as to improve market competitiveness, stabilize water temperature fluctuations, and save energy. The effect of factory space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

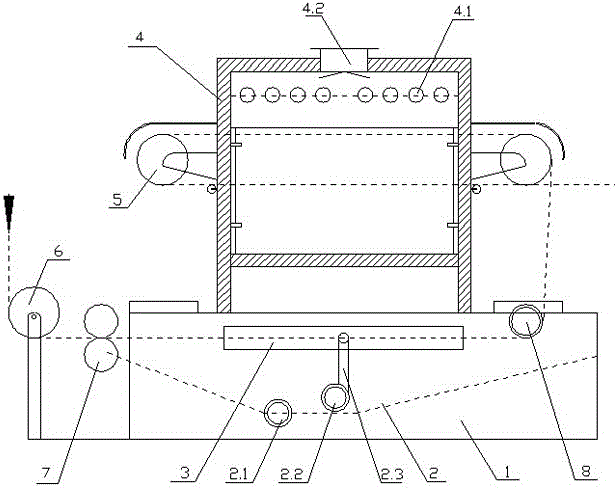

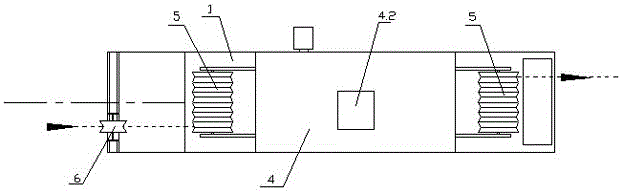

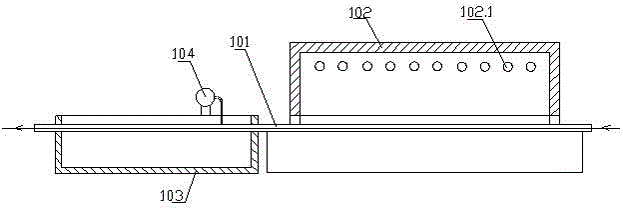

[0052] see Figure 1~4 , a kind of preparation technology of stainless steel wire that the present invention relates to, described technology comprises the following steps:

[0053] Step 1. Use an online film drying device to coat the wire with a film agent and dry it;

[0054] Step 2. Lead the wire into the rough-drawing straight-forward wire drawing machine and draw it continuously for 3 to 5 times;

[0055] Step 3, surface heat treatment, import the drawn wire into a heat treatment furnace for surface brightening treatment, at this time, the heating temperature in the heat treatment furnace is 1080±10°C; the forward speed of the wire is 5~6m / min; Water cooling, washing and drying;

[0056] Step 4, using an online film drying device to coat and dry the wire rod after step 3;

[0057] Step 5. Lead the wire into the fine-drawing straight-in wire drawing machine and draw it continuously for 3 to 5 times;

[0058] Step 6, surface heat treatment, import the drawn wire into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com