Non-steady state reactor and method for producing synthesis gas

A reactor and synthesis gas technology, applied in gaseous fuel, petroleum industry, fuel, etc., can solve problems that affect process thermal efficiency, synthesis gas yield, high temperature hot zone, spontaneous combustion and explosion hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

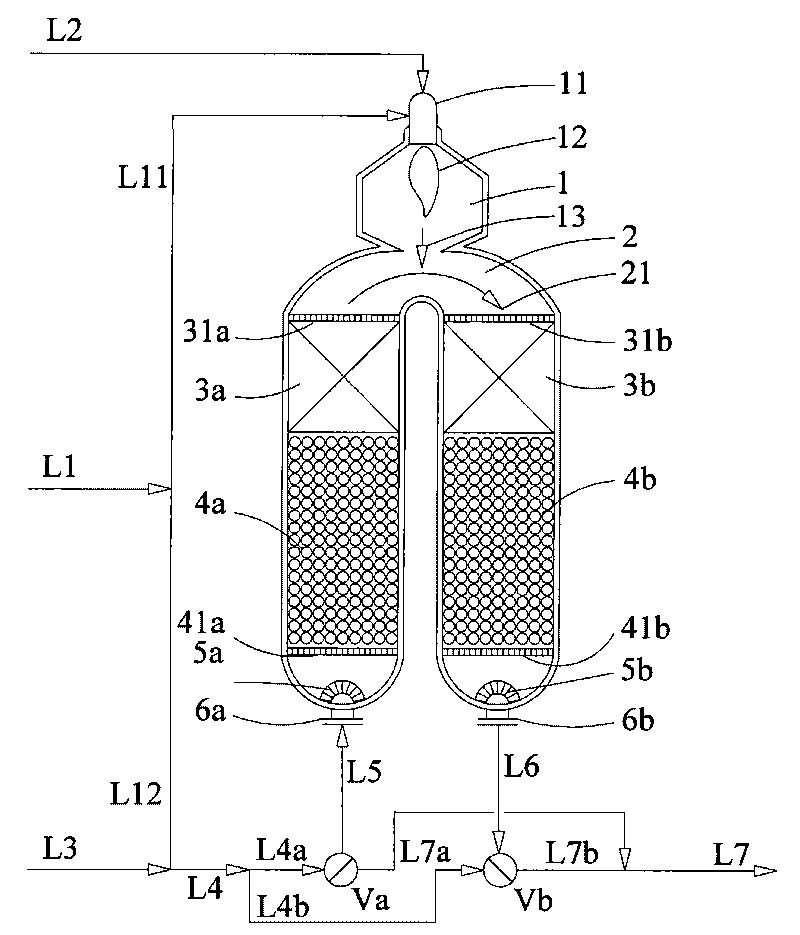

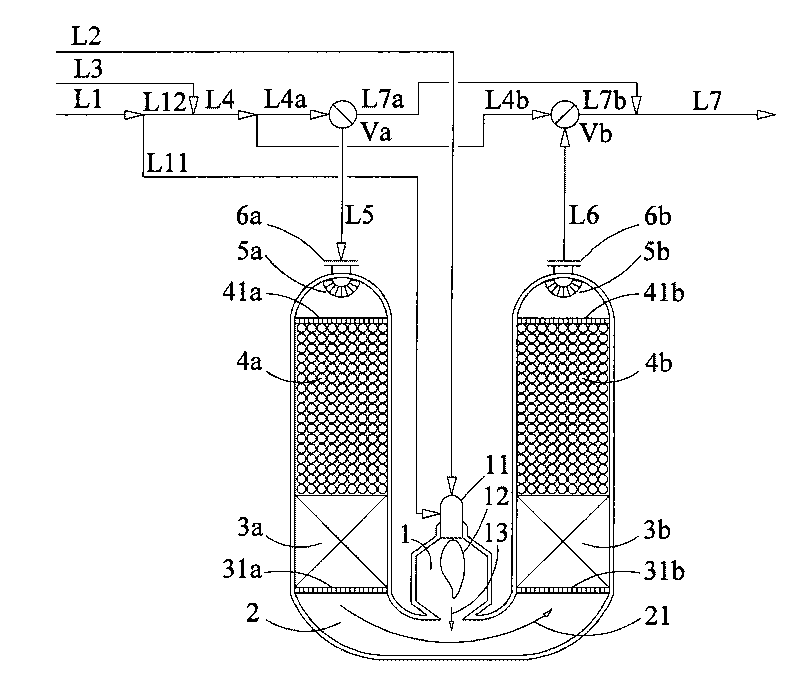

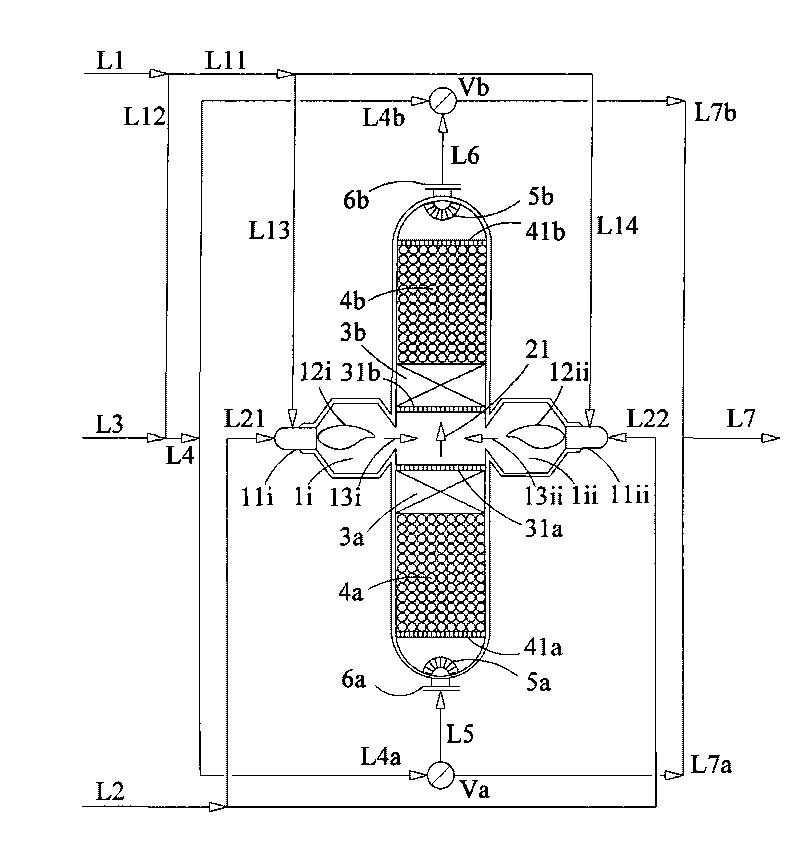

[0102] The present embodiment 1 and 2 are all in figure 1 In the shown reactor device, coal-based Fischer-Tropsch synthesis tail gas (TG) is used as raw material to produce synthesis gas, and the molar composition of the coal-based Fischer-Tropsch synthesis tail gas raw material is CH 4 25%, CO20%, H 2 30%, CO 2 20%, N 2 5%. The catalyst used in the reforming section of the reactor is a commercial steam reforming nickel catalyst; the heat storage section is filled with porcelain Raschig rings. Described reaction and result are as follows:

[0103] The intake flow rate of the raw material gas is 1000kmol / hr, the pressure is 25bar, and the temperature is 300°C; the optimal bypass feed ratio of the raw material gas is 0.38, that is, 62% of the raw material gas enters the combustion chamber through the burner along L11, and the other 38% of the raw material gas The gas enters the reactor from the bypass line L5 or L6 at the bottom of the reactor after being regulated by the f...

Embodiment 2

[0111] With coke oven gas (COG) as raw material, adopt the method identical with embodiment 1, carry out the synthetic gas experiment of regenerative autothermal reforming, result is as follows:

[0112] The composition of coke oven gas is CH 4 32%, CO 9%, H 2 52%, CO 2 3%, N 2 3.7%, O 2 0.3%, the feed flow rate is 1000kmol / hr, the optimal bypass feed ratio is 0.33; the oxygen feed flow rate is 190kmol / hr, and the feed O 2 / CH 4 is 0.59; bypass steam feed flow 600kmol / hr, H in the feed 2 O / CH 4 The ratio is 1.87.

[0113] The half-cycle time of the forced flow direction change in the reactor was 5 minutes.

[0114] After the reactor was started up, it took about 32 flow direction changes to reach a periodic steady state.

[0115] After the reactor reaches a periodic steady state, the fluctuating range of the outlet temperature of the feed preheating heat storage section is 984°C to 973°C, with an hourly average of 982°C; the fluctuating range of the outlet temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com