Method for realizing uniform heating and cooling of plastic injection mould

A technology of injection mold and uniform heating, applied in the field of heating and cooling of plastic injection molds, can solve the problems of uneven heating and cooling, and achieve the effect of uniform heating and cooling, uniform distance and high-quality appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

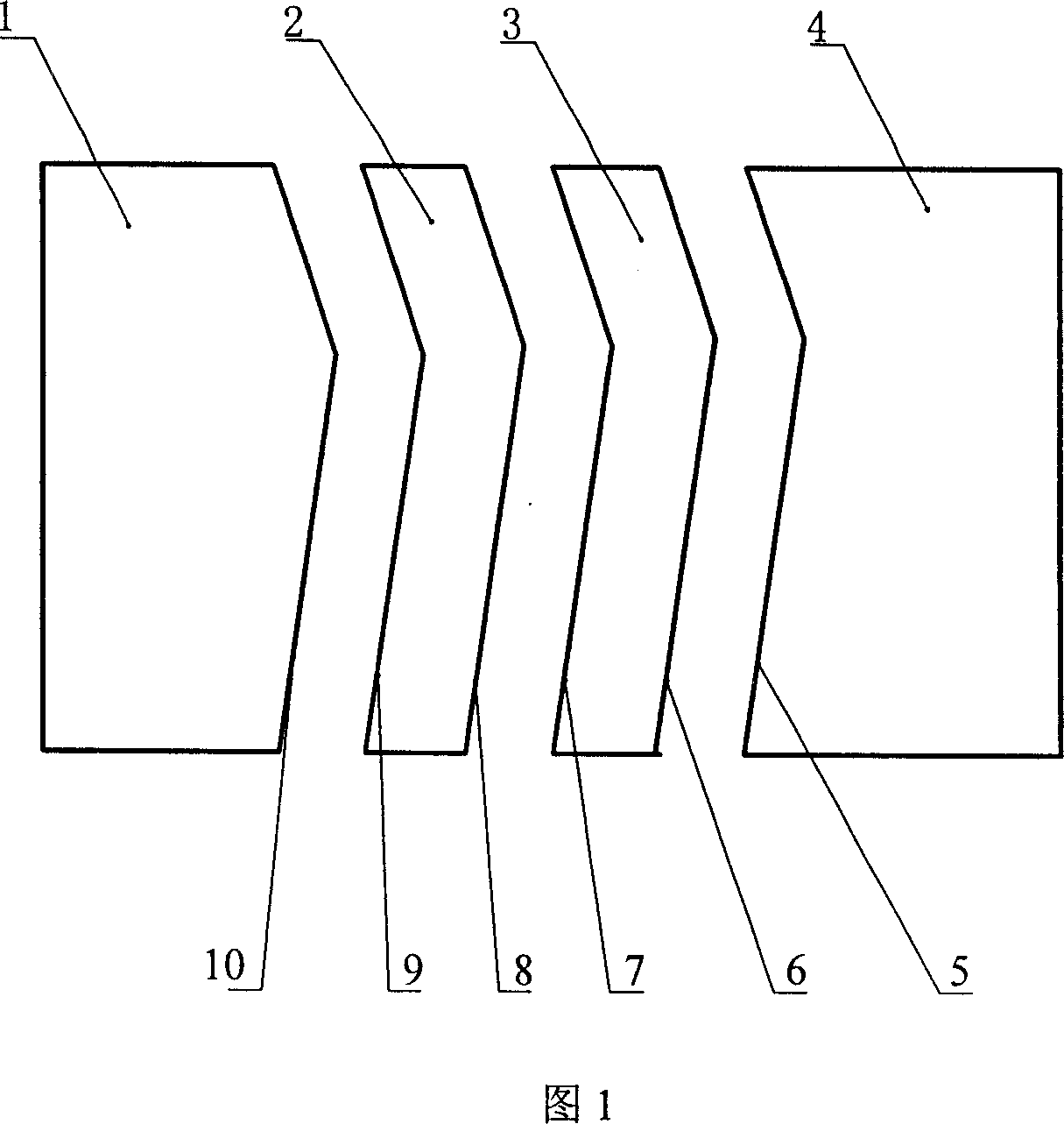

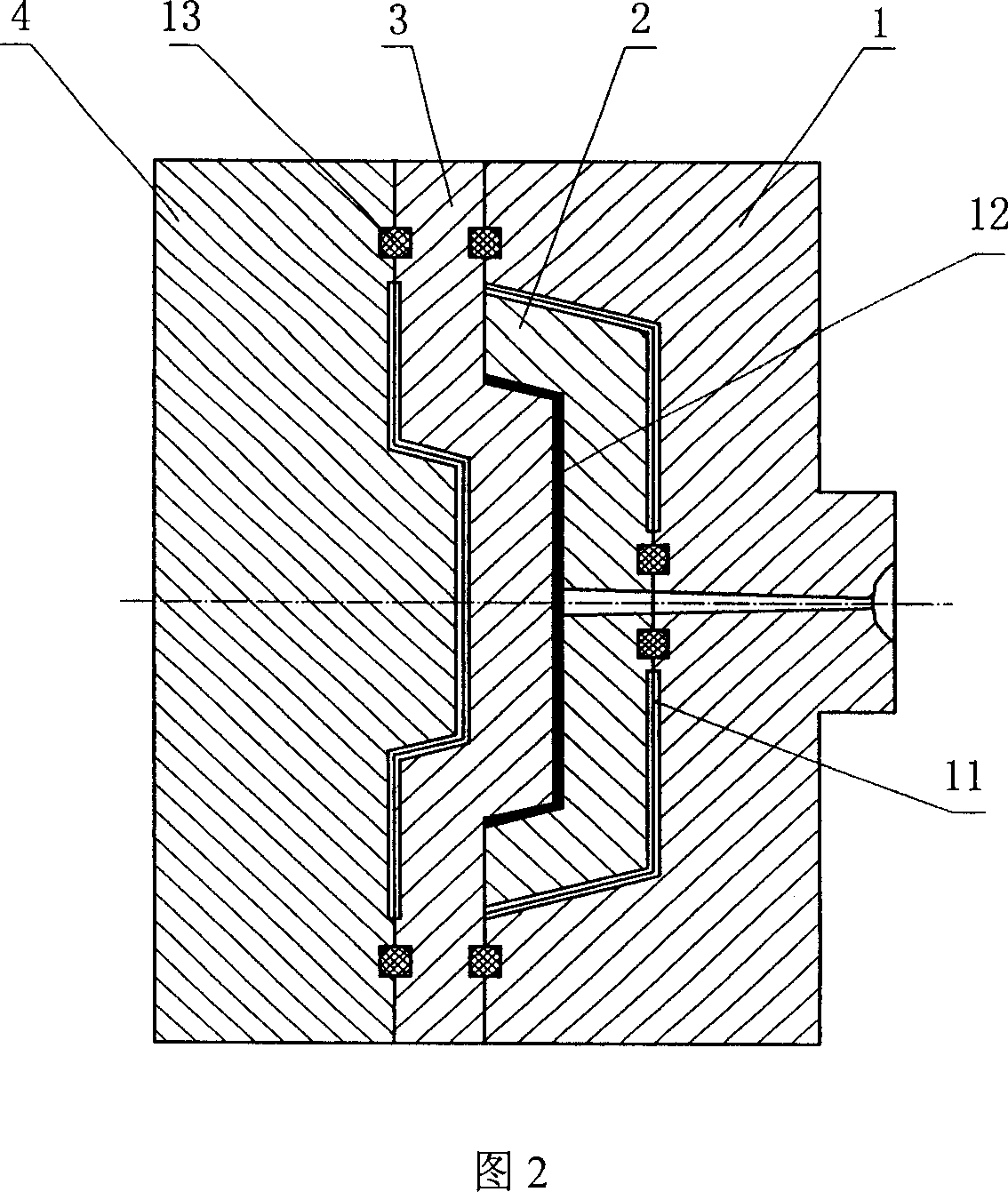

[0011] The method principle of the present invention is shown in Figure 1. At the position where the cavity of the fixed mold is offset by a certain distance, the fixed mold is divided into an outer part 1 of the fixed mold and an inner part 2 of the fixed mold according to the shape of the mold surface, so that the fixed mold is assembled from these two parts. The heating and cooling profile 9 of the inner part of the fixed mold and the heating and cooling profile 10 of the outer part of the fixed mold are consistent with the profile shape of the mold cavity profile 8 of the inner part of the fixed mold. Similarly, the movable mold is divided into the outer part 4 of the movable mold and the inner part 3 of the movable mold according to the shape of the mold surface, so that the movable mold is assembled from these two parts. The heating and cooling profile 6 of the inner part of the movable mold and the heating and cooling profile 5 of the outer part of the movable mold are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com