Cellular cylinder type vehicle engine waste heat power generator

An automotive engine, cylindrical technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of reducing working life, natural climate damage, reducing heat absorption area, etc., achieving uniform water cooling and heating, and easy assembly. Convenience and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

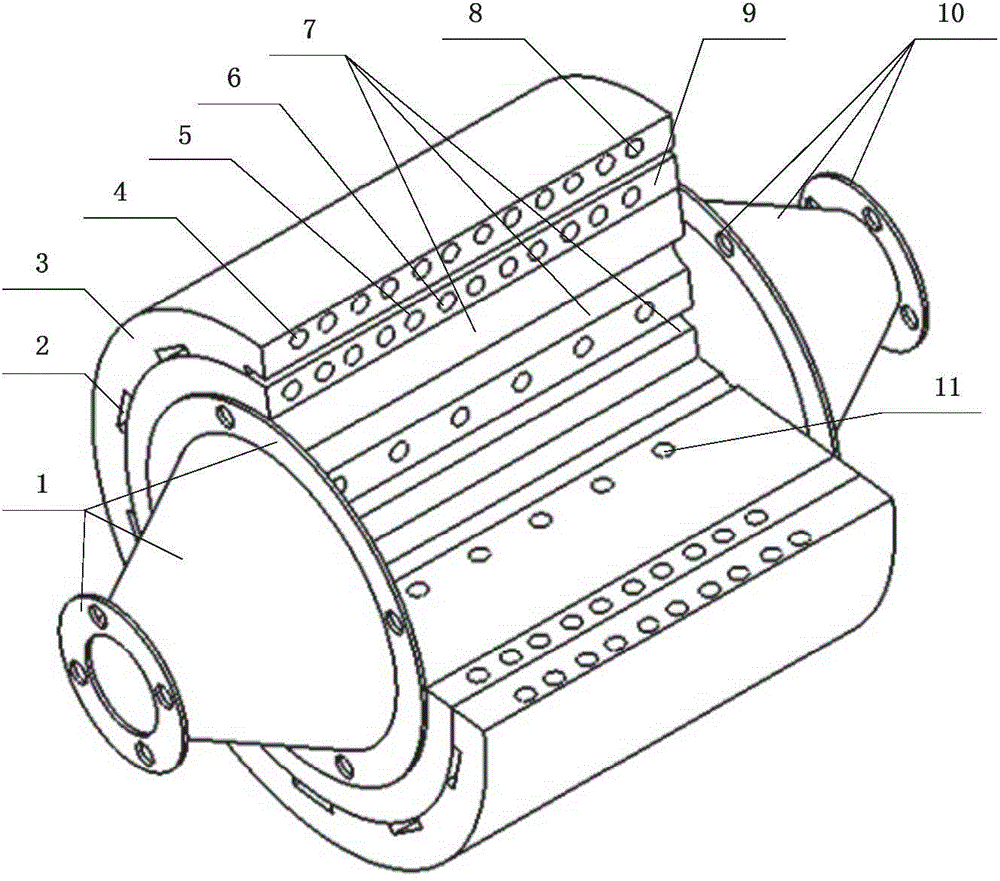

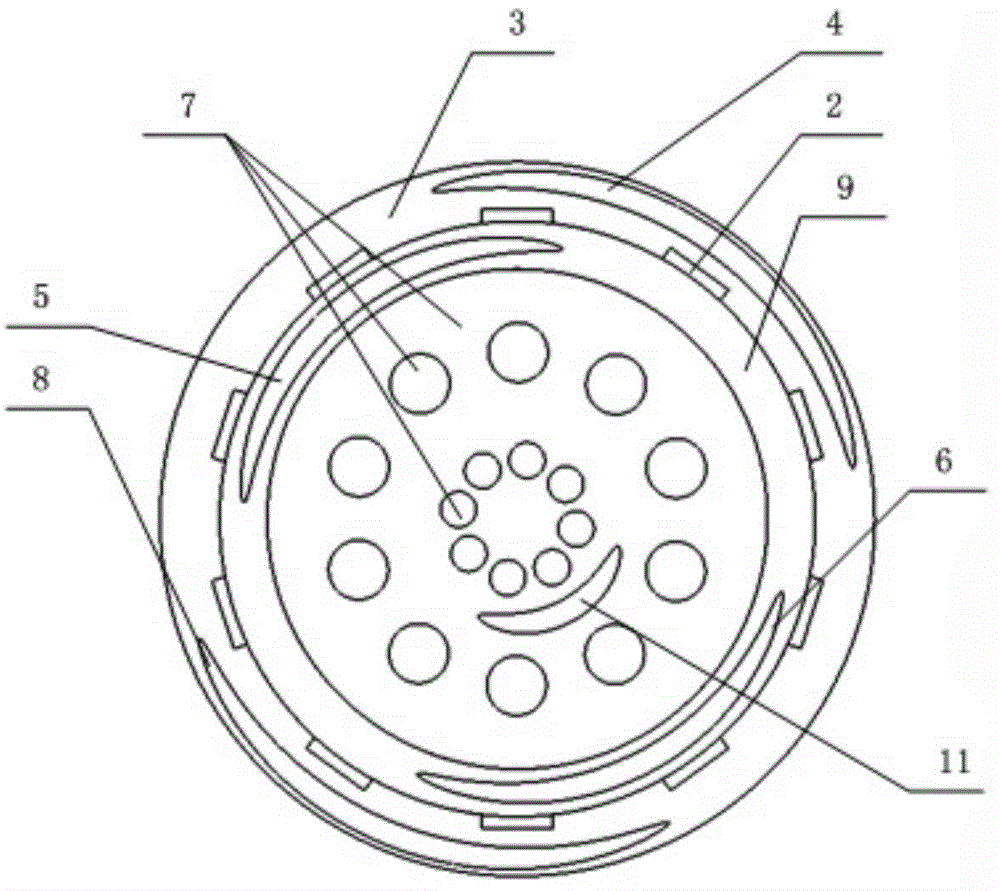

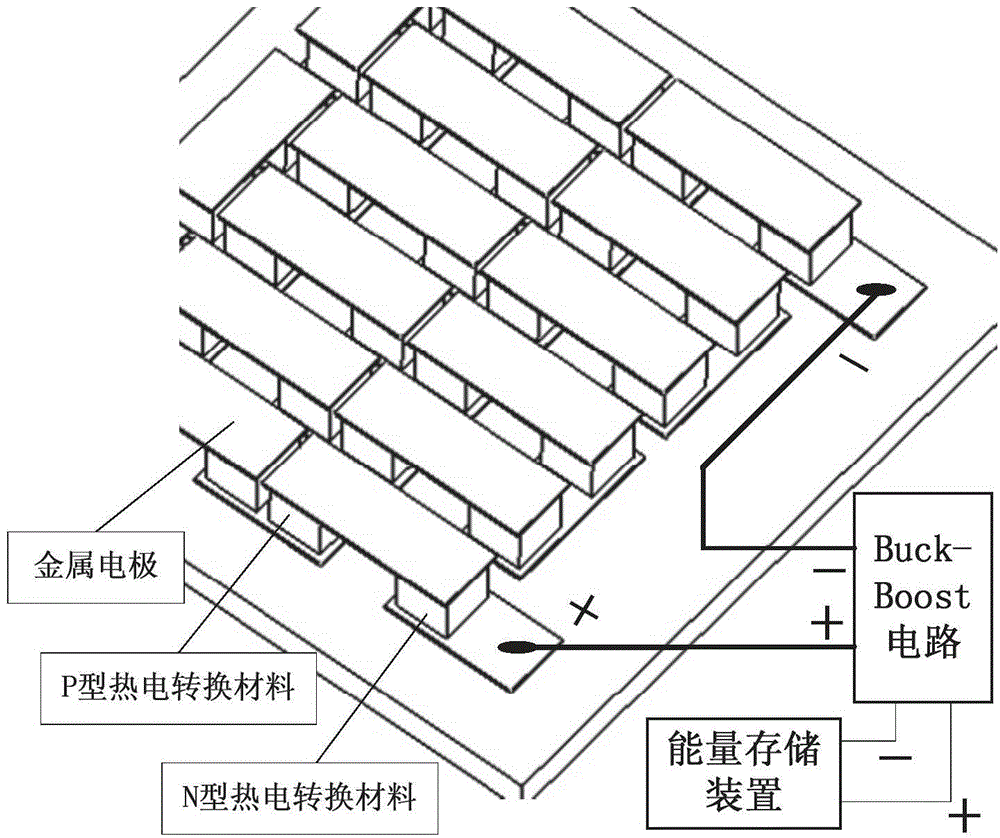

[0028] The waste heat power generation device of the honeycomb cylinder type automobile engine of the present invention comprises an intake end flange connection assembly 1, a thermoelectric power generation assembly 2, a water cooling plate 3, a water cooling plate cold water pipeline A4, a water cooling plate cold water pipeline B8, and a high temperature plate for heat exchange Medium channel A5, high temperature plate heat exchange medium channel B6, honeycomb heat exchanger 7, high temperature plate 9, air outlet flange connection assembly 10, heat exchange medium circulation channel 11. The radial sections of the high-temperature plate 9 and the water-cooled plate 3 are annular with a certain thickness, and the thermoelectric power generation assembly 2 is a square power generation assembly.

[0029] The water-cooled plate 3 is closely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com