A pressure type electric cooker and a control method therefor

A control method and rice cooker technology, which is applied to pressure cookers, kitchen utensils, household utensils, etc., can solve the problems of insufficient boiling of rice, crispy rice, and high cost, and achieve the reduction of control scheme costs, uniform heating and gelatinization, and structure simple high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

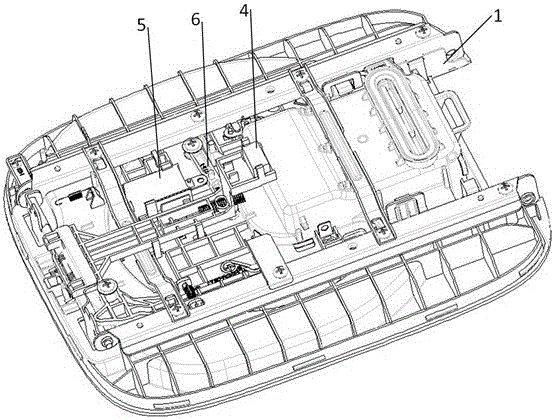

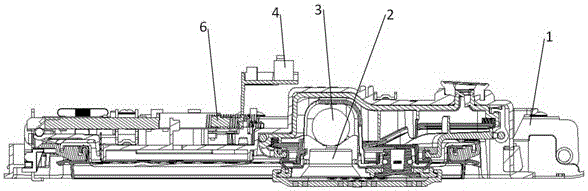

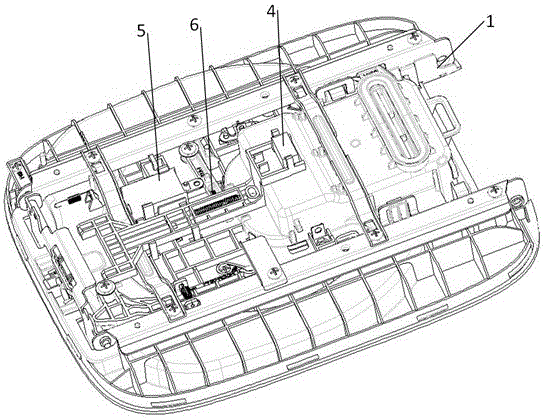

[0041] Such as Figure 1~7 As shown, a pressure-type electric rice cooker includes a pot body, an inner pot and an upper cover 1, the inner pot is placed in the pot body, and the upper cover 1 covers the pot body and the inner pot and is fastened on the pot body. The bottom of the body is provided with a thermostat, the upper cover 1 is provided with a pressure valve 3 for blocking the exhaust passage 2, the upper cover 1 is provided with a power source 5 and a driving mechanism 6 corresponding to the power source 5, The driving mechanism 6 is provided with an actuating part 4 for pressure relief, and the actuating part 4 is away from or close to the top of the pressure valve 3 .

[0042] The actuator part 4 used for pressure relief is magnetically adsorbed to the pressure valve 3 , and the gravity of the pressure valve 3 is greater than the magnetic force when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com