Tip clearance control for turbine blades

a turbine blade and tip clearance technology, applied in the direction of pump control, machines/engines, non-positive displacement fluid engines, etc., can solve the problems of blade tip clearance reduction, sfc also rises, mismatch in radial expansion, etc., to optimise the thermal responsiveness of the system, reduce unnecessarily large turbine tip clearance, and increase power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

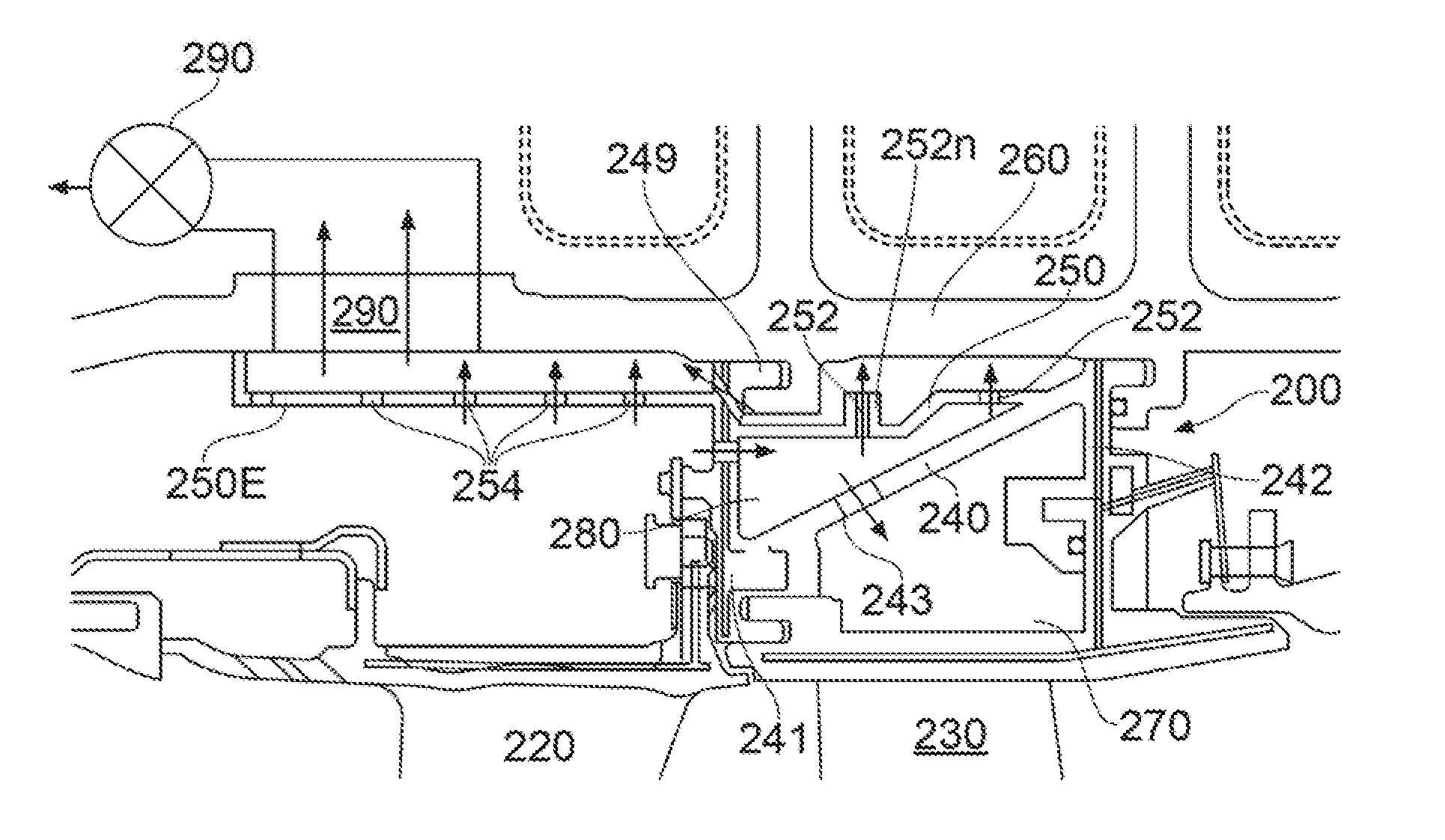

[0061]Referring firstly to FIGS. 3(a) and 3(b) (FIGS. 1 and 2 having already been described in the context of the prior art), here there is shown a first embodiment of the system of the invention, as applied to a HP section of a gas turbine engine, which may be any type of gas turbine engine. In the illustrated arrangement the engine casing 160 and carrier segment 100 are located generally radially outwardly of turbine blades (shown merely schematically as) 130 and HP nozzle guide vanes (NGV's) 120. Also shown are flap seal 148, and a mounting hook or rail 149. The latter has been moved into a relatively more radially outboard location in comparison with many known arrangements, in order to allow an integrally formed undulating carrier wall 140, comprising a series of equi-spaced sinusoidal (or other wave function) corrugations 146, to be accommodated so that the elongate axially oriented peak regions or lands of each corrugation 146 are positioned at a generally uniform and equal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com