Environment-protective SEBS fresh-preservation film and producing method thereof

A production method and technology of fresh-keeping film, applied in environment-friendly SEBS fresh-keeping film and its production field, can solve problems such as slow degradation, non-biodegradable PVC, and human health hazards, and achieve simple production process, excellent mechanical properties, and excellent transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

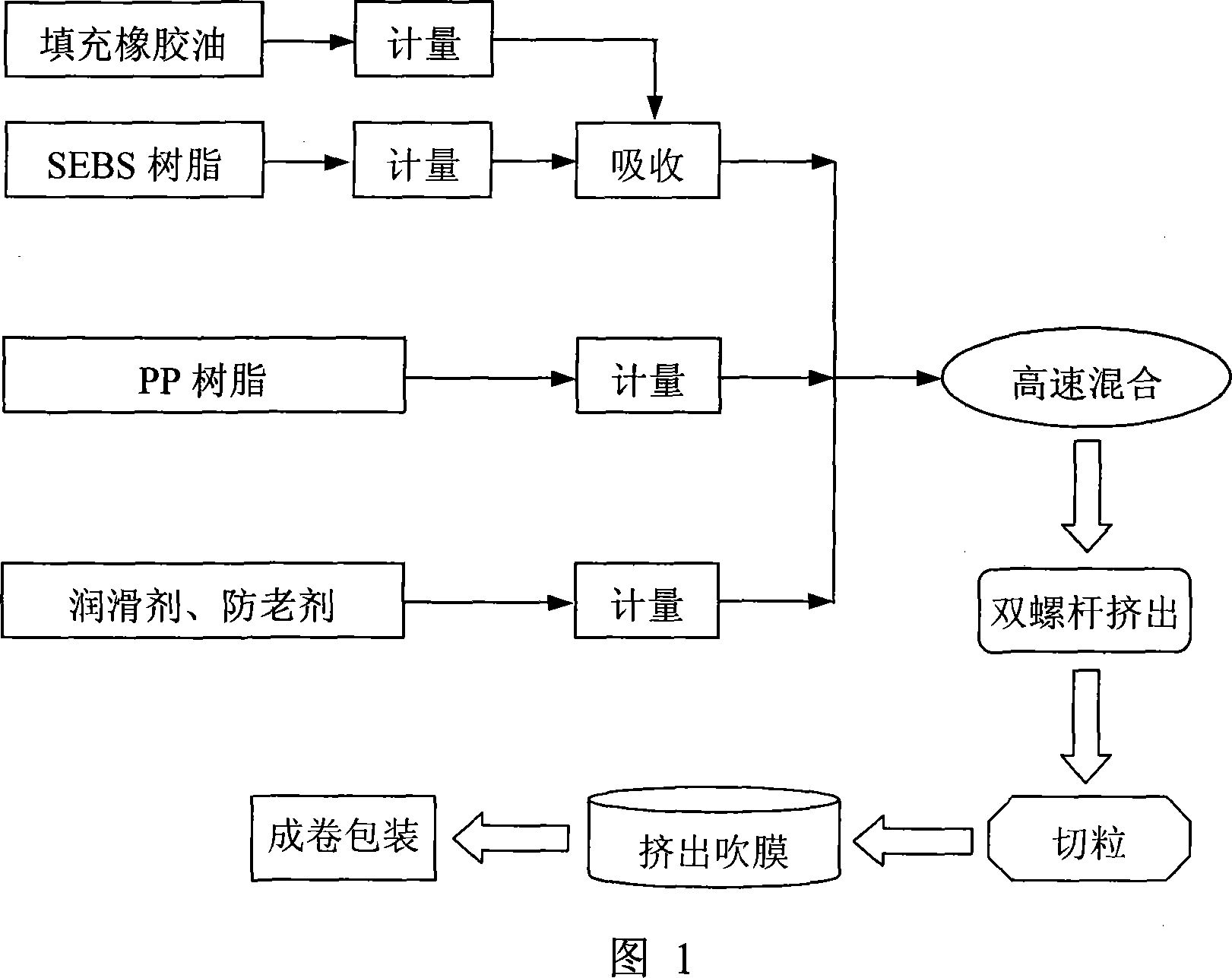

Method used

Image

Examples

example 1

[0042] First weigh 100 parts by mass of high molecular weight SEBS resin, 75 parts by mass of naphthenic rubber filler oil, 40 parts by mass of copolymerized polypropylene, 0.20 parts by mass of ethylene bisstearamide, 0.20 parts by mass of zinc stearate, polyethylene wax 0.20 parts by mass, 0.2 parts by mass of tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol, 0.20 parts by mass of tris(2,4-di-tert-butylphenyl)phosphite share;

[0043] Then, let the SEBS resin fully absorb the rubber filling oil;

[0044] Next, add the SEBS resin that has absorbed the rubber filling oil and other raw materials into the mixer and mix evenly, then use a twin-screw extruder to granulate. ℃, 185℃, 185℃, 185℃, 185℃, head temperature 185℃;

[0045] Finally, use a plastic extrusion blown film machine to extrude the blown film and pack it in rolls. The temperature of the main part of the film extruder starts from the feeding port, and it is 160°C, 170°C, 180°C, 180°C, 18...

example 2

[0047] First weigh 100 parts by mass of low molecular weight SEBS resin, 75 parts by mass of naphthenic rubber filler oil, 25 parts by mass of paraffin-based rubber filler oil, 85 parts by mass of homopolypropylene, 0.30 parts by mass of ethylene bisoleic acid amide, hard 0.20 parts by mass of calcium fatty acid, 0.20 parts by mass of polyethylene wax, 0.20 parts by mass of octadecyl propionate, 0.20 parts by mass of beta (3', 5'-di-tert-butyl-4'-hydroxyphenyl) propionate, tris(2,4 -di-tert-butylphenylcarboxylate) 0.15 parts by mass;

[0048] Then, let the SEBS resin fully absorb the rubber filling oil;

[0049] Next, add the SEBS resin that has absorbed the rubber filling oil and other raw materials into the mixer and mix evenly, then granulate with a twin-screw extruder. ℃, 190℃, 190℃, 190℃, 190℃, head temperature 185℃;

[0050] Finally, use a plastic extrusion blown film machine to extrude the blown film and pack it in rolls. The temperature of the main body of the film e...

example 3

[0052] First weigh 50 parts by mass of high molecular weight SEBS resin, 50 parts by mass of low molecular weight SEBS resin, 100 parts by mass of paraffin-based rubber filler oil, 45 parts by mass of copolymerized polypropylene, 45 parts by mass of homopolymerized polypropylene, ethylene dioleic acid 0.30 parts by mass of amides, 0.20 parts by mass of calcium stearate, 0.20 parts by mass of polyethylene wax, 0.1 parts by mass of silicone resin, tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol 0.30 parts by mass, 0.10 parts by mass of tris(2,4-di-tert-butylphenyl)phosphite, 0.05 parts by mass of dilauryl thiodipropionate;

[0053] Then, let SEBS completely absorb the rubber filling oil;

[0054] Next, add the SEBS resin that has absorbed the rubber filling oil and other raw materials into the mixer and mix evenly, then use a twin-screw extruder to granulate. ℃, 185℃, 190℃, 190℃, 190℃, head temperature 185℃;

[0055] Finally, use a plastic extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com