Degradable film and preparation method thereof

A technology for degrading film and film blowing machine is applied in the field of degradable composite film and its preparation, which can solve the problems affecting the mechanical properties of film materials, the compatibility needs to be further improved, and the application field is limited, so as to improve product competitiveness and reduce Preparation cost and effect of broadening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

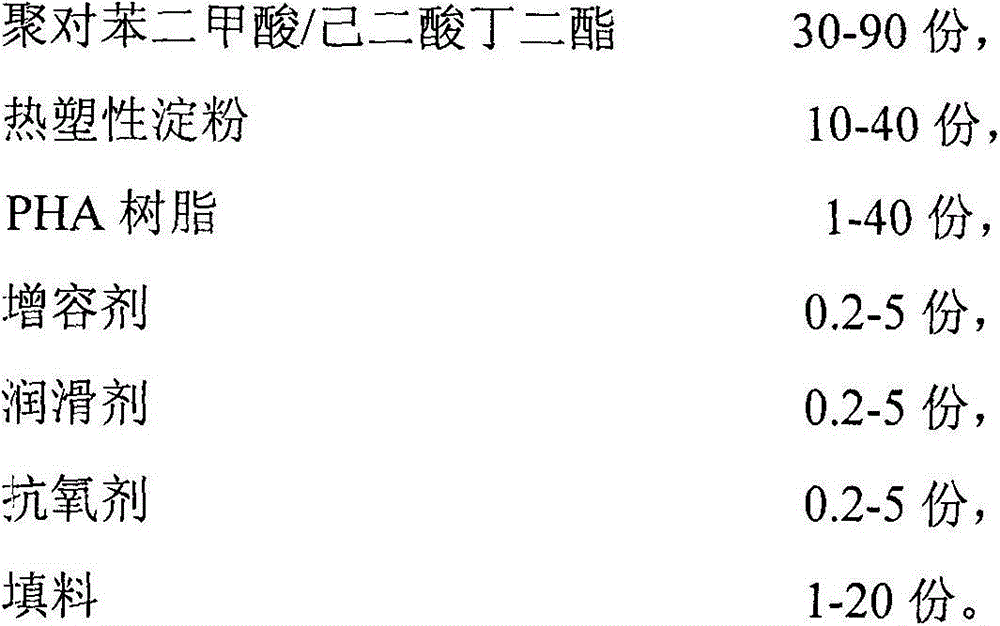

[0026] (1) Dry polybutylene terephthalate / adipate, thermoplastic starch, PHA resin and fillers, wherein the drying of polybutylene terephthalate / adipate, thermoplastic starch and polyvinyl alcohol The temperature is 60°C, the filler drying temperature is 90°C, and the time is 12h;

[0027] (2) Weigh 90 parts of polybutylene terephthalate / adipate, 10 parts of thermoplastic starch, 1 part of PHA resin, 0.2 part of compatibilizer acrylic acid, 0.2 part of antioxidant 264 and 1 part of filler talcum powder, Mix evenly in a high mixer, mixing time 3min;

[0028] (3) Add the mixed material into a twin-screw extruder for melt blending, then strand and pelletize to obtain blended pellets, and the extrusion temperature is 100° C.;

[0029] (4) Extrude step (3) blended granules and 0.2 parts of lubricant methylene bis stearamide through a single-screw extruder, and blow molding at a film blowing machine to obtain a degradable film, wherein the feeding of the film blowing machine The t...

Embodiment 2

[0032] (1) Dry polybutylene terephthalate / adipate, thermoplastic starch, PHA resin and fillers, wherein the drying of polybutylene terephthalate / adipate, thermoplastic starch and polyvinyl alcohol The temperature is 70°C, the filler drying temperature is 100°C, and the time is 10h;

[0033] (2) Weigh 70 parts of polybutylene terephthalate / adipate, 20 parts of thermoplastic starch, 10 parts of PHA resin, 1 part of compatibilizer maleic anhydride, 0.9 parts of antioxidant 1010 and 10 parts of filler carbonic acid Barium, mixed evenly in a high mixer, mixing time 5min;

[0034] (3) Add the mixed material into a twin-screw extruder for melt blending, then strand and pelletize to obtain blended pellets, and the extrusion temperature is 120° C.;

[0035] (4) Extrude the blended granules of step (3) and 1 part of lubricant erucamide through a single-screw extruder, and blow them in a blown film machine to obtain a degradable film, wherein the feed temperature of the blown film machi...

Embodiment 3

[0038] (1) Dry polybutylene terephthalate / adipate, thermoplastic starch, PHA resin and fillers, wherein the drying of polybutylene terephthalate / adipate, thermoplastic starch and polyvinyl alcohol The temperature is 80°C, the filler drying temperature is 110°C, and the drying time is 8h;

[0039] (2) Weigh 50 parts of polybutylene terephthalate / adipate, 30 parts of thermoplastic starch, 20 parts of PHA resin, 3 parts of compatibilizer maleic anhydride grafted ethylene octene copolymer, 2 parts of antioxidant Agent 168 and 20 parts of filler calcium carbonate, mixed uniformly in a high mixer, mixing time 7min;

[0040] (3) Add the mixed material into a twin-screw extruder for melt blending, then strand and pelletize to obtain blended pellets, and the extrusion temperature is 150° C.;

[0041] (4) Extrude and blow the blended granules in step (3) and 2 parts of lubricant sodium stearate through a single-screw extruder to obtain a degradable film. The tempering section temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com