Method for blowing film and making bag by using full biodegradable material as base material

A biodegradable material and all-biological technology, applied in the field of film blowing and bag making based on all-biodegradable materials, can solve the problems of lack of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1, the base material of fully biodegradable materials is the "MaterBi" brand product that Italian NOVMANT company has added polyvinyl alcohol (PVA) to starch since the 1990s. The film blowing and bag making methods include:

[0028] 1) homework preparation;

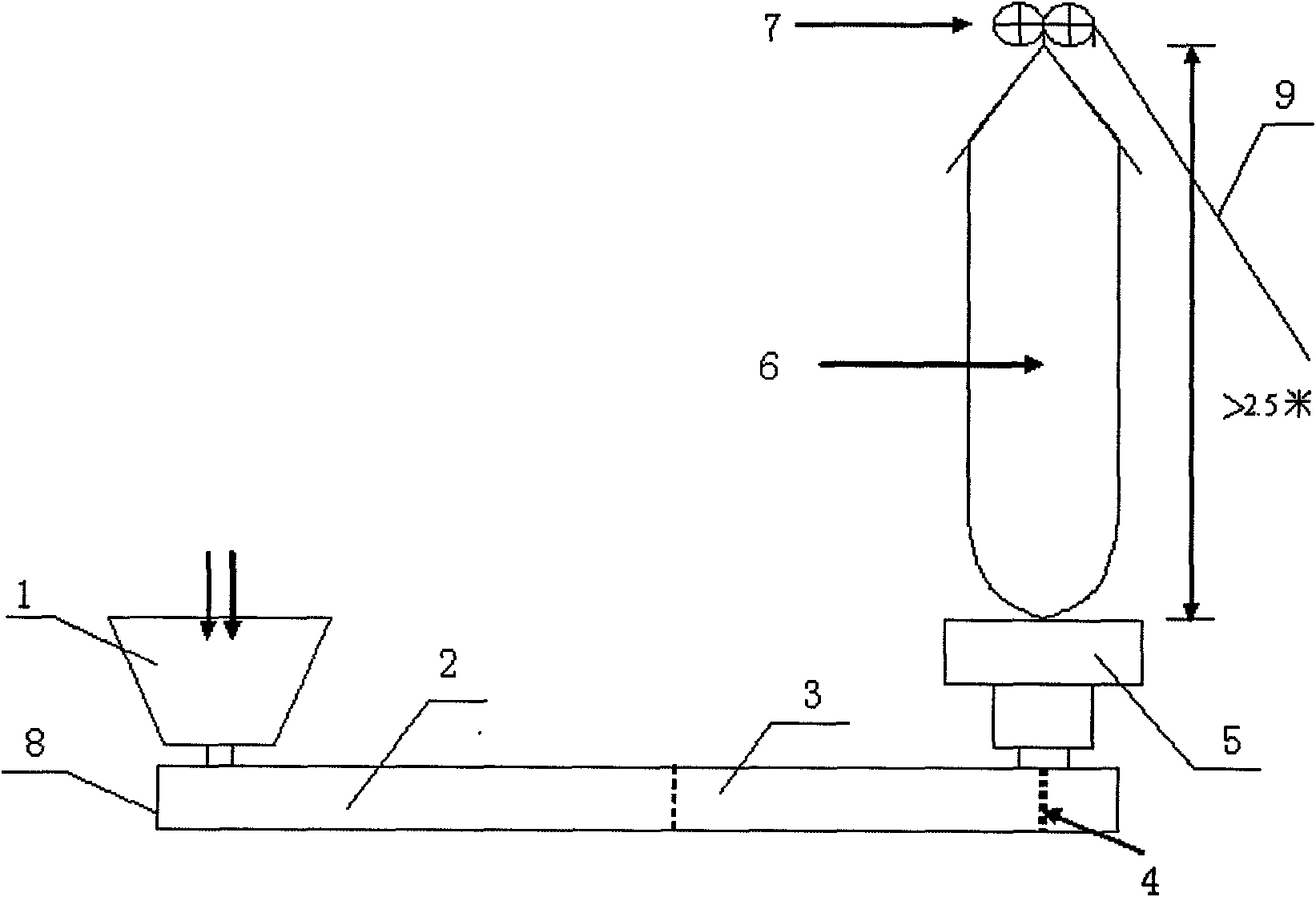

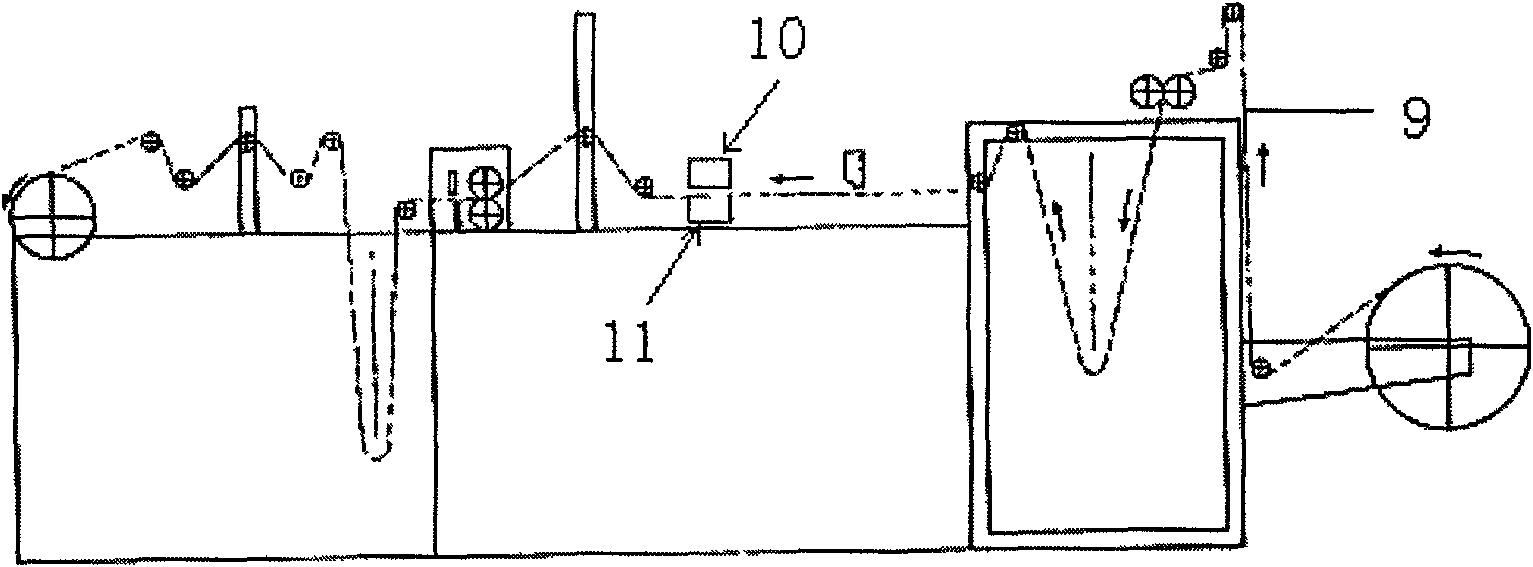

[0029] 2) Film blowing: add color masterbatch, then blow film, and finally get a film; process parameters include:

[0030] a) Control the temperature of the plasticizing section of the film blowing machine to be 130°C, the temperature of the homogenizing section to be 142°C, and the temperature of the extrusion section to be 140°C;

[0031] b) The screw length-to-diameter ratio L / D of the film blowing machine is 30: 1; the inflation ratio is 1: 2.5; the height from the die mouth to the traction roller is 3m;

[0032] c) The screw speed is 18 rpm at the start, and then gradually increases the speed until it catches up with the winding speed of the film;

[0033] 3) Bag making: heat-sealing, sealing, and b...

example 2

[0040] Example 2, the base material of the fully biodegradable material is an aliphatic aromatic random copolyester (Ecoflex) based on polyester and starch developed by BASF in Germany, and the film blowing and bag making methods include:

[0041] 1) homework preparation;

[0042] 2) Film blowing: add color masterbatch, then blow film, and finally get a film; process parameters include:

[0043] a) Control the temperature of the plasticizing section of the film blowing machine to be 122°C, the temperature of the homogenizing section to be 146°C, and the temperature of the extrusion section to be 142°C;

[0044] b) The length-to-diameter ratio of the screw of the film blowing machine is L / D32:1; the inflation ratio is 1:2.8; the height from the die mouth to the traction roller is 3.5m;

[0045] c) The screw speed is 25 rpm at the start, and then gradually increases the speed until it catches up with the winding speed of the film;

[0046] 3) Bag making: heat-sealing, sealing,...

example 3

[0053] Example 3, the base material of fully biodegradable materials is made of BF materials blended with thermoplastic starch (TPS), aliphatic polyester (AP) and natural plasticizers (glycerin and sorbitol) from Biograde Australia, blown film, and made into bags method, the steps include:

[0054] A film blowing and bag making method based on fully biodegradable materials, the steps comprising:

[0055] 1) homework preparation;

[0056] 2) Film blowing: add color masterbatch, then blow film, and finally get a film; process parameters include:

[0057] a) Control the temperature of the plasticizing section of the film blowing machine to be 140°C, the temperature of the homogenizing section to be 150°C, and the temperature of the extrusion section to be 145°C;

[0058] b) The screw length-to-diameter ratio L / D of the film blowing machine is 35: 1; the inflation ratio is 1: 3; the height from the die mouth to the traction roller is 4m;

[0059] c) The screw speed is 35 rpm at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com