Ecological environment-friendly light-conversion mulching film

A mulching film and environmental protection technology, applied in the direction of plant protection cover, etc., can solve the problems of poor light transmittance and can not meet the requirements, etc., and achieve the effect of long service life, remarkable effect and ideal soil burial degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

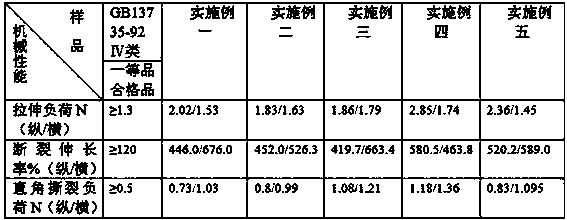

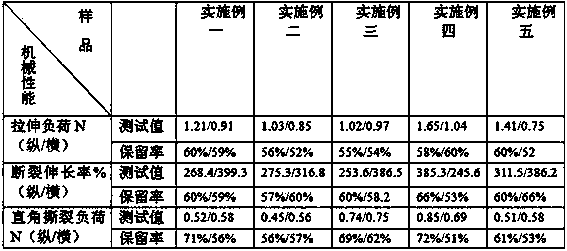

Examples

Embodiment 1

[0025] (1) Preparation of nano-degradation light-converting masterbatch: mixing the raw materials of nano-degradation light-converting masterbatch, high-speed stirring and kneading, plasticizing and extruding strands, drying, and pelletizing to obtain nano-degradation light-converting masterbatch. The raw materials and their weight percentages are: linear low-density polyethylene powder: 40%, low-density polyethylene: 10%, polyolefin elastomer: 10%, metallocene polyethylene: 10%, nano-sized corn biostarch: 12%, light transfer agent: 3.0%, antioxidant: 2.0%, dispersant stearic acid: 3.0%, dispersant polyethylene wax: 3.0%, heat preservation agent hydrotalcite: 7%.

[0026] The melt flow rate of the prepared nano-degradation light conversion masterbatch is 3.5g / 10min.

[0027] (2) Preparation of mulch film: Mix the prepared nano-degradation light-converting masterbatch and other raw materials according to their weight percentages, and send them to the film blowing machine for pl...

Embodiment 2

[0031] (1) Preparation of nano-degradation light conversion masterbatch: the steps are the same as in Example 1, and the raw materials and their weight percentages are: linear low-density polyethylene powder: 45%, low-density polyethylene: 8%, polyolefin elastomer : 8%, Metallocene Polyethylene: 9%, Nano Corn Biostarch: 12%, Brightening Agent: 3.0%, Antioxidant: 2.0%, Dispersant Stearic Acid: 3.0%, Dispersant Polyethylene Wax: 3.0 %, insulation agent hydrotalcite: 7%.

[0032] The melt flow rate of the prepared nano-degradation light conversion masterbatch is 3.2g / 10min.

[0033] (2) Preparation of mulch film: the steps are the same as in Example 1, and the raw materials and their weight percentages are: linear low-density polyethylene: 35%, low-density polyethylene: 15%, metallocene linear polyethylene: 20%, polyolefin Elastomer: 15%, nano-degradation light conversion masterbatch 15%.

[0034] Mulch products are pink.

Embodiment 3

[0036] (1) Preparation of nano-degradation light conversion masterbatch: the steps are the same as in Example 1, and the raw materials and their weight percentages are: linear low-density polyethylene powder: 50%, low-density polyethylene: 6%, polyolefin elastomer : 6%, Metallocene Polyethylene: 8%, Nano Corn Biostarch: 12%, Brightening Agent: 3.0%, Antioxidant: 2.0%, Dispersant Stearic Acid: 3.0%, Dispersant Polyethylene Wax: 3.0 %, insulation agent hydrotalcite: 7%.

[0037] The melt flow rate of the prepared nano-degradation light conversion masterbatch is 3.7g / 10min.

[0038] (2) Preparation of mulch film: the steps are the same as in Example 1, and the raw materials and their weight percentages are: linear low-density polyethylene: 40%, low-density polyethylene: 15%, metallocene linear polyethylene: 15%, polyolefin Elastomer: 15%, nano-degradation light conversion masterbatch 15%.

[0039] Mulch products are pink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com