Inorganic powder highly filled polyolefin decorative paper and manufacturing method thereof

A technology of inorganic powder and decorative paper, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of large proportion of products, high processing difficulty, reduce melt viscosity, etc., and achieve mechanical strength High, good paper texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

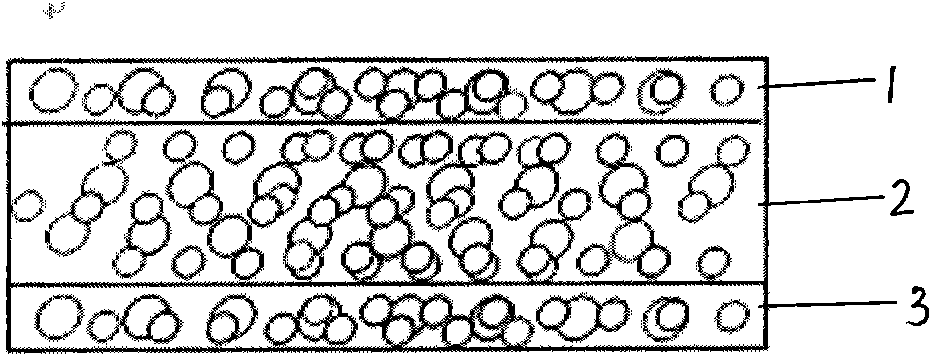

[0028]Add 70% of heavy calcium carbonate into the high-speed mixer, and heat to 130±5°C to remove moisture. Add 0.85% titanate coupling agent for surface treatment, the temperature is controlled at 110±2°C, the treatment time is 20 minutes, add HDPE 6%, LLDPE 15%, LDPE 8% and antioxidant 0.15% and mix for 5 minutes, then use Extruded and granulated by twin-screw extruder to make special material. The blowing agent microspheres (the weight is 1.8% of the special material) of the special material of the above-mentioned preparation and the azodicarbonamide of the surface coating polyolefin elastomer, stearic acid and zinc oxide in the mixer at a low speed (80 rpm / min) mixed for 5 minutes to make foam. Blow the film according to the three extruders added to the three-layer co-extrusion blown film machine, the proportion of the three layers is 20% for the inner and outer layers, and 60% for the middle layer. The temperature in each zone of the extruder is set to 160-195°C, and t...

Embodiment 2

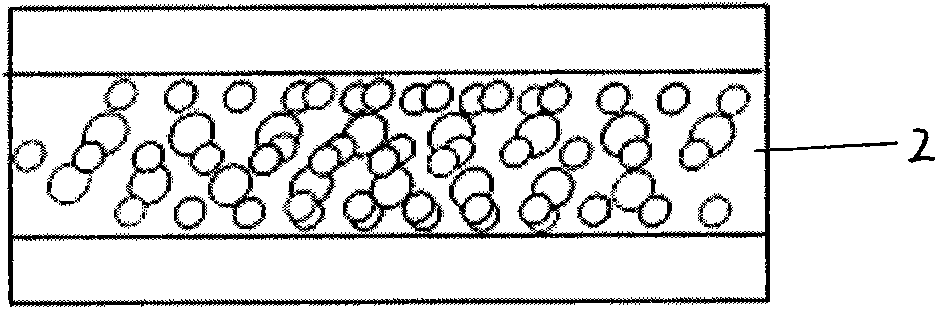

[0030] Add 60% of heavy calcium carbonate and 24.7% of kaolin into a high-speed mixer, and heat to 130±5°C to remove water. Add 0.3% titanate coupling agent for surface treatment, the temperature is controlled at 110±2°C, the treatment time is 20 minutes, add HDPE 6%, LLDPE 6.8%, LDPE 2% and antioxidant 0.2% and mix for 5 minutes, then use Extruded and granulated by twin-screw extruder to make special material. Get the special material of above-mentioned preparation and the microsphere (weight is 1.8% of special material) of sodium carbonate, sodium bicarbonate and citric acid mixture of surface coating liquid low-molecular polyisobutylene, low speed (60 rev / min) in mixer Mix for 8 minutes to make a foaming material, add it to the middle feed extruder in the three-layer co-extrusion blown film machine, and then take the special material (without foaming microspheres) prepared by the above process and add it to the three layers In the co-extrusion blown film machine, the inner...

Embodiment 3

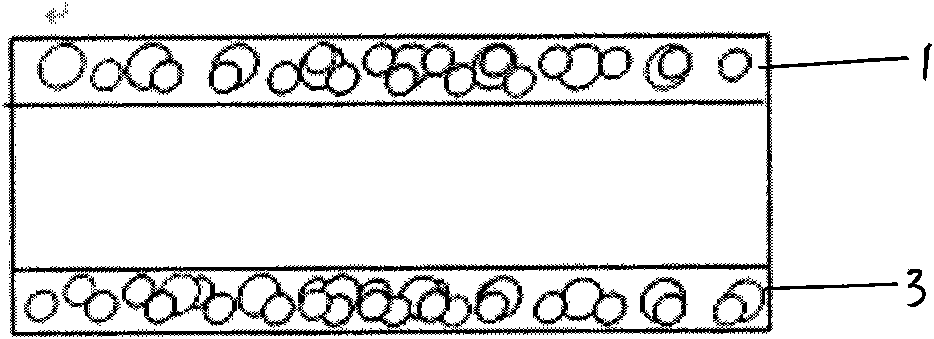

[0032] Add 30% of heavy calcium carbonate, 27.5% of kaolin, 2% of wet-process white carbon black, and 13% of talcum powder into a high-speed mixer, and heat to 140±5°C to remove water. Add 2.5% of aluminate coupling agent for surface treatment, the temperature is controlled at 120±2°C, the treatment time is 15 minutes, add HDPE 9%, LLDPE 8.8%, LDPE 7% and antioxidant 0.2% and mix for 5 minutes, then use Put it into a pressurized internal mixer, mix at 150°C for 10 minutes, and then extrude and granulate through a twin-screw extruder to make a special material. Get the special material of above-mentioned preparation and the polymer microsphere (weight is 2.5% of special material) that contains low-boiling point liquid, mix 5 minutes at low speed (60 revs / min) in mixer and make foaming material, take foaming material Add it to the inner and outer layer feed extruder in the three-layer co-extrusion blown film machine, and then add the special materials (without foaming microspher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com