Antibacterial degradable fresh-keeping food packaging material and preparation thereof

A food packaging and weight technology, applied in the field of food packaging materials, can solve the problems of chitosan's weak antibacterial performance, inability to prevent food from rotting, and no fresh-keeping effect, etc. It is easy to industrialize large-scale production, has good fresh-keeping effect, and is easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

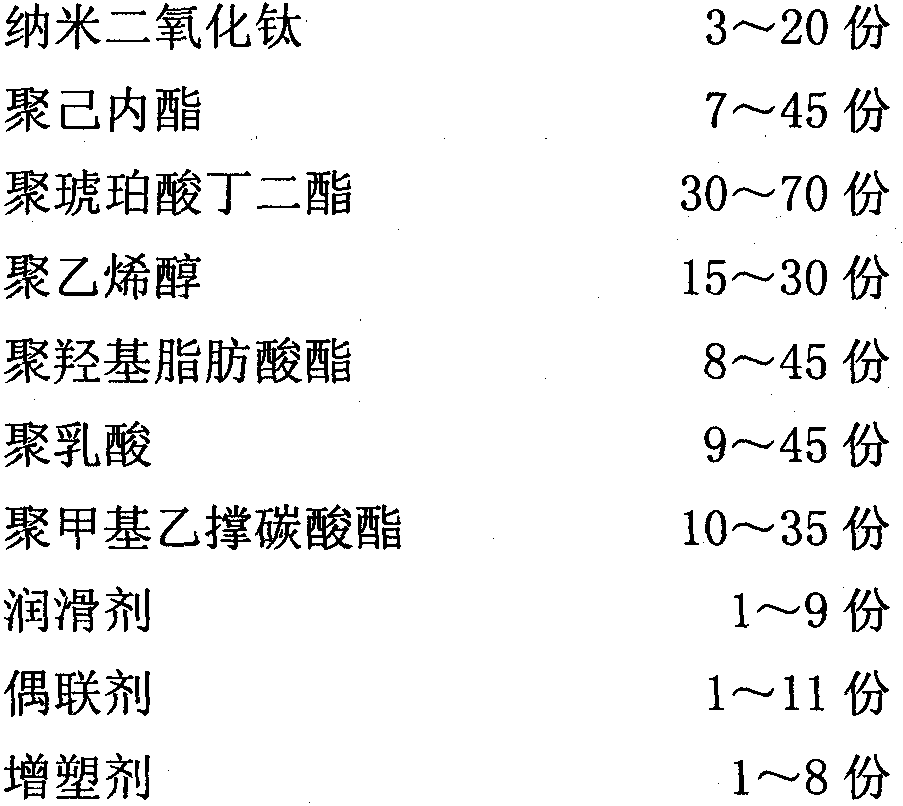

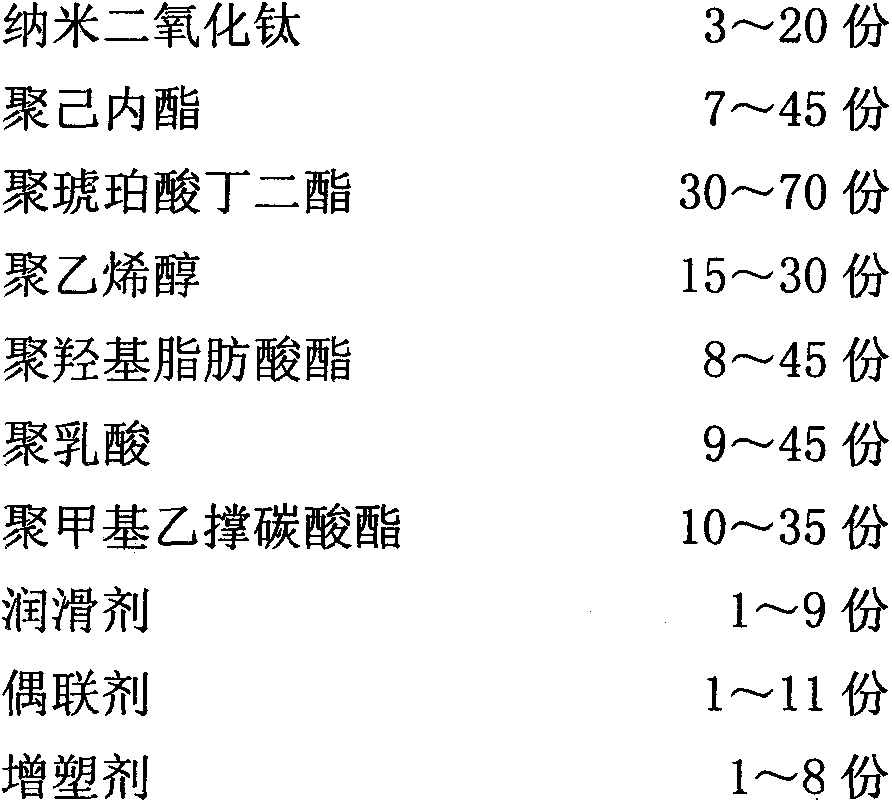

Method used

Image

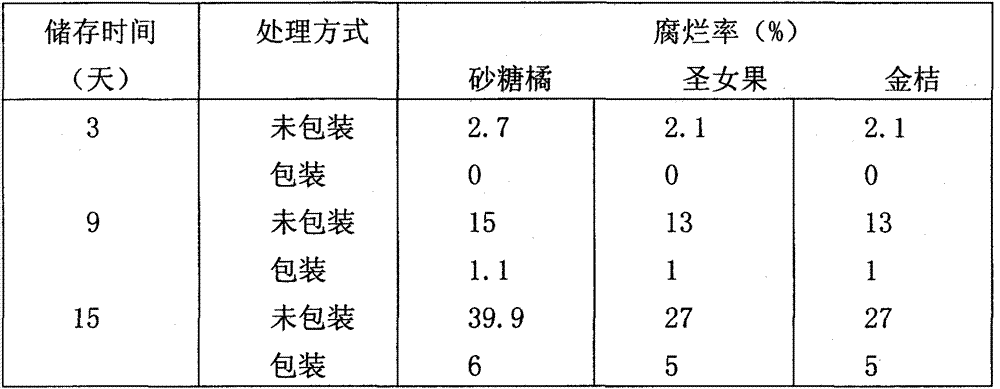

Examples

Embodiment 1

[0021] Embodiment 1. with high-speed mixer with 50 gram nano titanium dioxide, 200 gram polycaprolactone (molecular weight is in the scope of 20000), 500 gram polybutylene succinate (molecular weight is in the scope of 10000), 200 gram polyvinyl alcohol ( Molecular weight in the range of 10,000), 200 grams polyhydroxyalkanoate (molecular weight in the range of 15,000), 200 grams of polylactic acid (molecular weight in the range of 20,000), 600 grams of polymethylethylene carbonate (molecular weight in the range of 40,000) 55 grams of acetylated citric acid, 25 grams of tetraisopropyl titanate, and 15 grams of butyl stearate were uniformly mixed to obtain a mixed material, and then the mixed material was added to a single-screw extruder for melt blending (The mixed materials pass through the melting and blending intervals with temperatures of 135°C, 145°C, 150°C, 155°C, 155°C, 160°C, 155°C, and 150°C in turn) and then drawn and pelletized to obtain granular mixed Resin, the gra...

Embodiment 2

[0022] Embodiment 2. with high-speed mixer with 0.5 kilogram of nano-titanium dioxide, 2 kilograms of polycaprolactone (molecular weight is in the scope of 30000), 5 kilograms of polybutylene succinate (molecular weight is in the scope of 20000), 2 kilograms of polyvinyl alcohol ( Molecular weight in the range of 20,000), 2 kg polyhydroxyalkanoate (molecular weight in the range of 20,000), 2 kg polylactic acid (molecular weight in the range of 30,000), 6 kg polymethylethylene carbonate (molecular weight in the range of 50,000) 0.2 kilograms of calcium stearate, 0.3 kilograms of n-octyltriethoxysilane, and 0.3 kilograms of sorbitol are uniformly mixed to obtain mixed materials, and then the mixed materials are added to a single-screw extruder for melt blending ( The mixed materials are sequentially passed through the melting and blending intervals with temperatures of 135°C, 145°C, 150°C, 155°C, 155°C, 160°C, 155°C, and 150°C) and then drawn and pelletized to obtain granular mix...

Embodiment 3

[0023] Embodiment 3. with high-speed mixer with 0.6 kilogram of nano titanium dioxide, 3 kilograms of polycaprolactone (molecular weight is in the scope of 40000), 6 kilograms of polybutylene succinate (molecular weight is in the scope of 30000), 2.5 kilograms of polyvinyl alcohol ( Molecular weight in the range of 30,000), 3 kg of polyhydroxyalkanoate (in the range of molecular weight in the range of 35,000), 3 kg of polylactic acid (in the range of molecular weight in the range of 40,000), 7 kg of polymethylethylene carbonate (in the range of molecular weight in the range of 60,000) , 0.15 kg of stearic acid, 0.4 kg of tetrabutyl titanate, and 0.5 kg of citric acid were uniformly mixed to obtain a mixed material, and then the mixed material was added to a single-screw extruder for melt blending (the mixed material Sequentially pass through the melting and blending intervals with temperatures of 135°C, 145°C, 150°C, 155°C, 155°C, 160°C, 155°C, and 150°C) and then draw strands ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com