Full-degradable cushion packaging bag and preparation method thereof

A packaging bag, fully degradable technology, applied in the field of fully degradable cushioning packaging bags, can solve the problem of white pollution of cushioning packaging bags, and achieve good mechanical properties and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

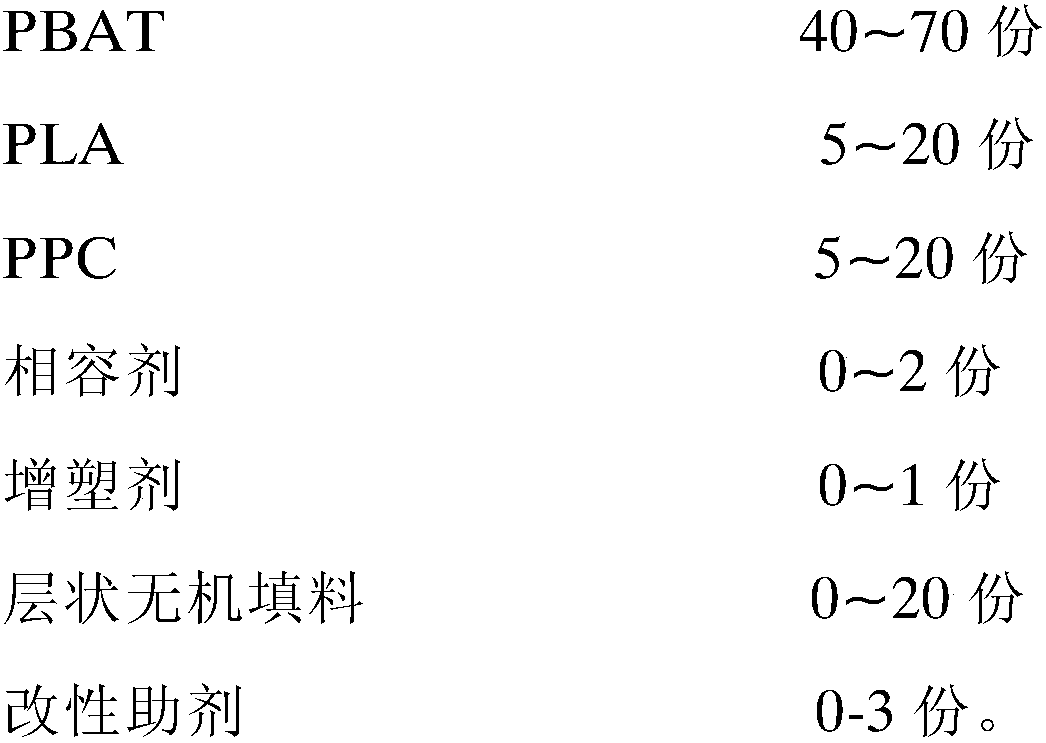

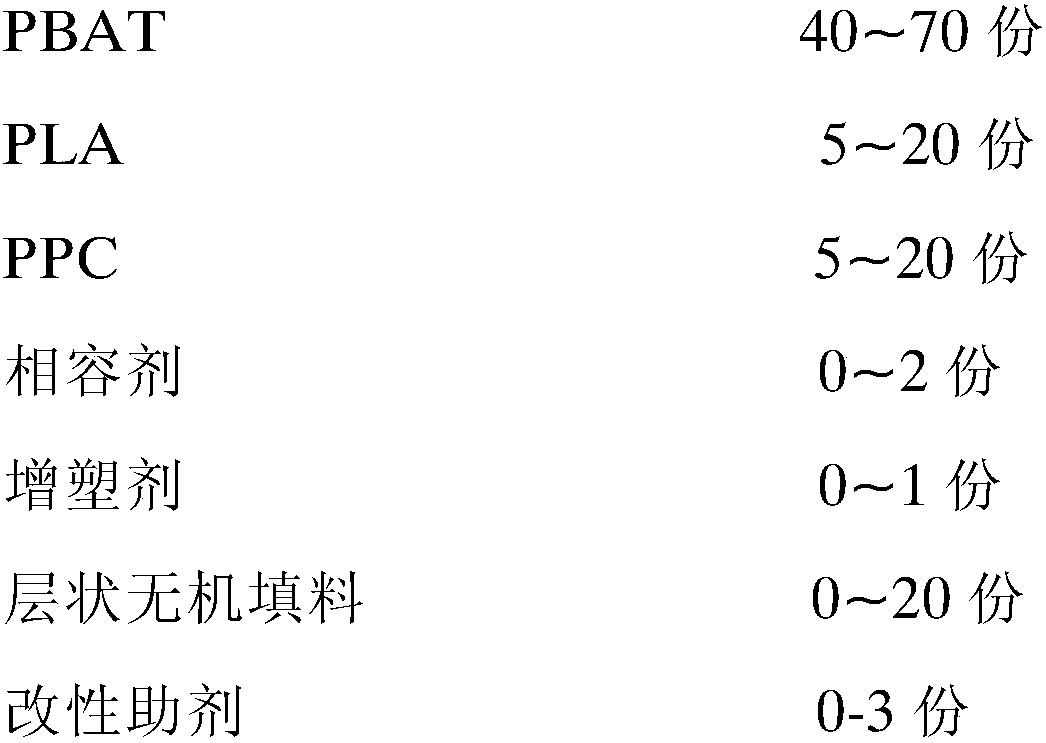

Method used

Image

Examples

Embodiment 1

[0024] 40 parts of PBAT were weighed and dried in a blast oven at 80°C for 6 hours, and 20 parts of PLA were dried in a blast oven at 60°C for 12 hours for later use. Then add 15 parts of talcum powder to a high-speed mixer with a temperature of 120°C and stir at a speed of 600r / min for 10 minutes, then add 2 parts of silane coupling agent modification additive in two times, and stir for 5 minutes each time. 800r / min to obtain modified talcum powder for subsequent use. Finally add 2 parts of compatibilizer oligomeric epoxy chain extender, 1 part of epoxidized soybean oil, 15 parts of modified talc powder and dry PBAT and PLA, add them to the high-speed mixer and mix them evenly, then add them to the twin-screw extruder In the machine, melt and blend, extrude strands, cut pellets, and use a three-layer co-extrusion blown film machine to blown film products. After bag making, cutting, inflation, heat sealing and packaging, a fully degradable cushioning packaging bag is obtained....

Embodiment 2

[0026] 50 parts of PBAT were weighed and dried in a blast oven at 80°C for 6 hours, and 15 parts of PLA were dried in a blast oven at 60°C for 12 hours for later use. Then add 16 parts of mica stone powder to a high-speed mixer at a temperature of 120°C and stir at a speed of 600r / min for 10 minutes, then add 1.5 parts of aluminate coupling agent modification aid twice, and stir for 5 minutes each time. The stirring speed is 800r / min, and the modified mica stone powder is obtained for later use. Finally, add 1.5 parts of compatibilizer GMA, 1 part of white oil, 16 parts of modified mica stone powder and dry PBAT and PLA to a high-speed mixer and mix evenly, then add them to a twin-screw extruder for melt blending and extrusion. Strips and pellets are blown into film products using a three-layer co-extrusion blown film machine, and fully degradable cushioning packaging bags are obtained through bag making, slitting, inflation, heat sealing and packaging.

Embodiment 3

[0028] 55 parts of PBAT were weighed and dried in a forced air oven at 80°C for 6 hours, and 10 parts of PLA were dried in a forced air oven at 60°C for 12 hours for later use. Then add 16.5 parts of kaolinite powder to a high-speed mixer with a temperature of 120°C and stir at a speed of 600r / min for 10 minutes, then add 1.5 parts of zinc stearate modification additive in two times, stir for 5 minutes each time, and stir The speed is 800r / min, and the modified kaolinite powder is obtained for later use. Finally, add 2 parts of compatibilizer GMA, 0.5 parts of citric acid, 16.5 parts of modified kaolinite powder and dry PBAT and PLA, add them to a high-speed mixer and mix them evenly, then add them to a twin-screw extruder for melt blending and extrusion Stretch, pelletize, use three-layer co-extrusion blown film machine to blow mold film products, and get fully degradable cushioning packaging bags through bag making, cutting, inflation, heat sealing and packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com