Vacuum plastic suction embossing roll

A technology of vacuum forming and embossing rollers, which is applied in the direction of flat products, household appliances, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

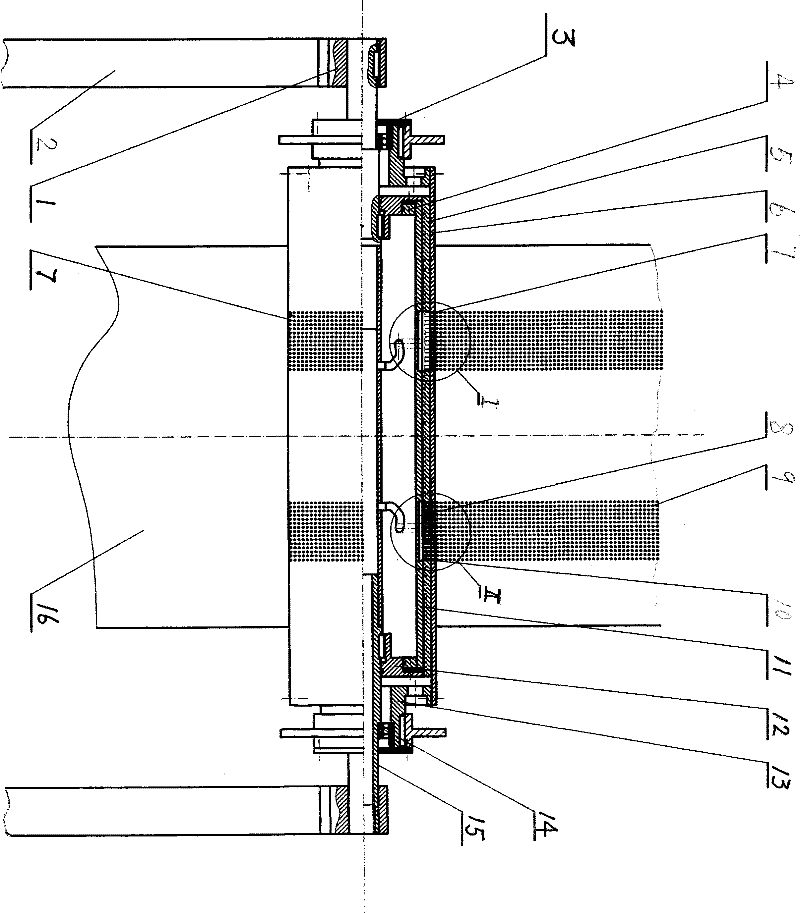

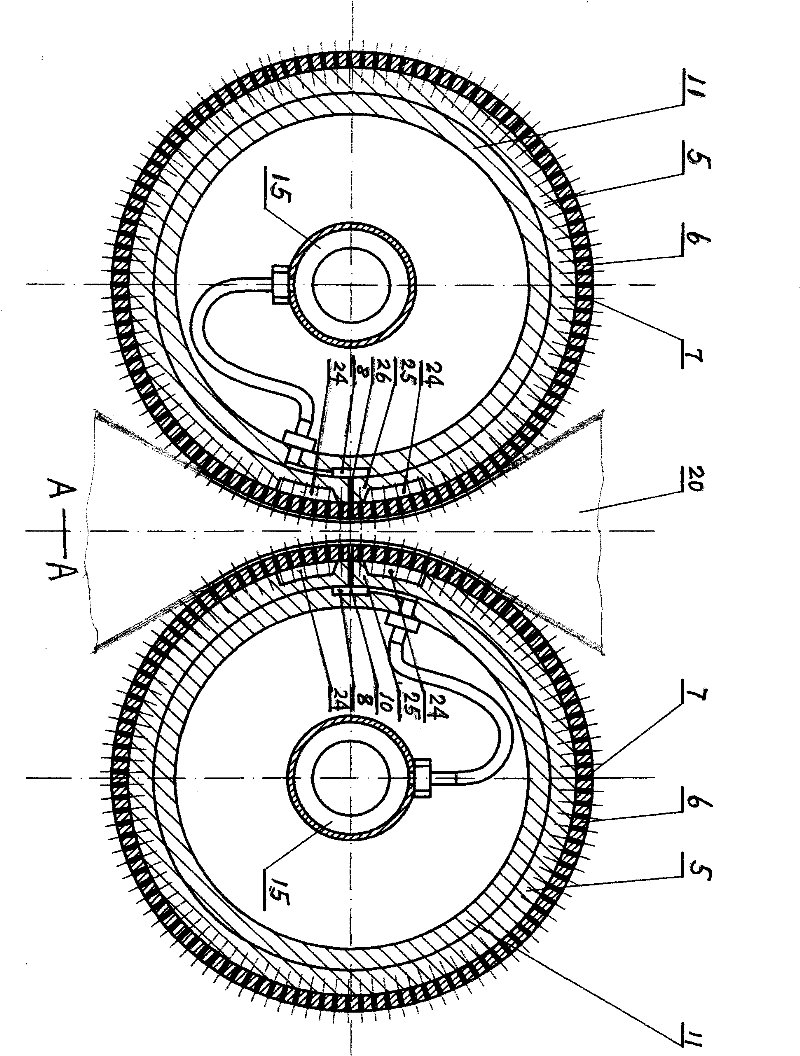

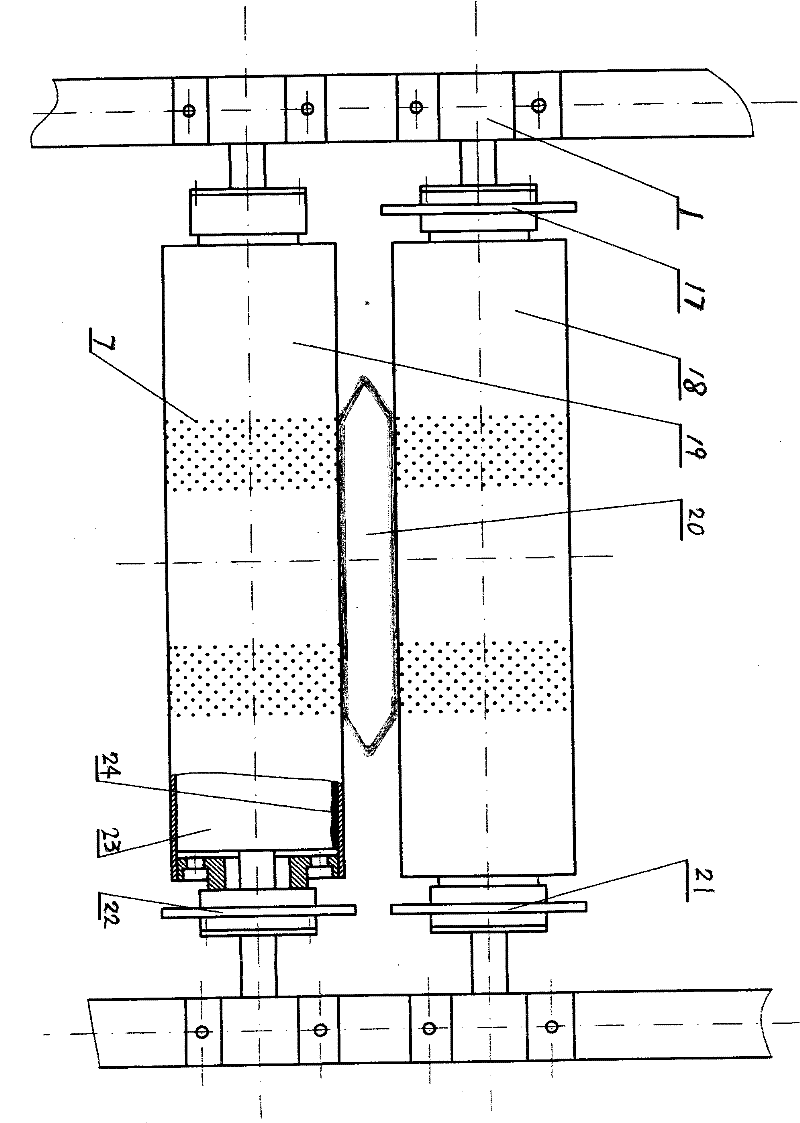

[0016] In the figure, the vacuum-absorbing embossing rollers are two vacuum-absorbing rollers with the same structure, which are installed parallel to each other on the frame 2. The two rollers rotate in opposite directions and have equal linear speeds through mechanical transmission. The vacuum blister embossing roller is made up of driving roller 18 and passive roller 19. The two ends of the outer mold roller 6 on the driving roller 18 are respectively equipped with a disc end cover 13, a bearing chamber is arranged at the center of the disc end cover 13, and a rolling bearing 14 is installed in the bearing chamber, and the bearing cover 3 is installed on the bearing In the chamber, the rolling bearing 14 and the hollow shaft 15 on the suction roller 23 are assembled into one body. The disc end covers 13 at both ends of the outer mold roller 6 are respectively equipped with transmission wheels, and one of the transmission wheels 17 forms a transmission with an external power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com