Novel film blowing machine

A film blowing machine, a new type of technology, applied in the field of film production, can solve the problems of uneven force, large floor space, low efficiency, etc., and achieve the effects of ensuring quality, saving floor space, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

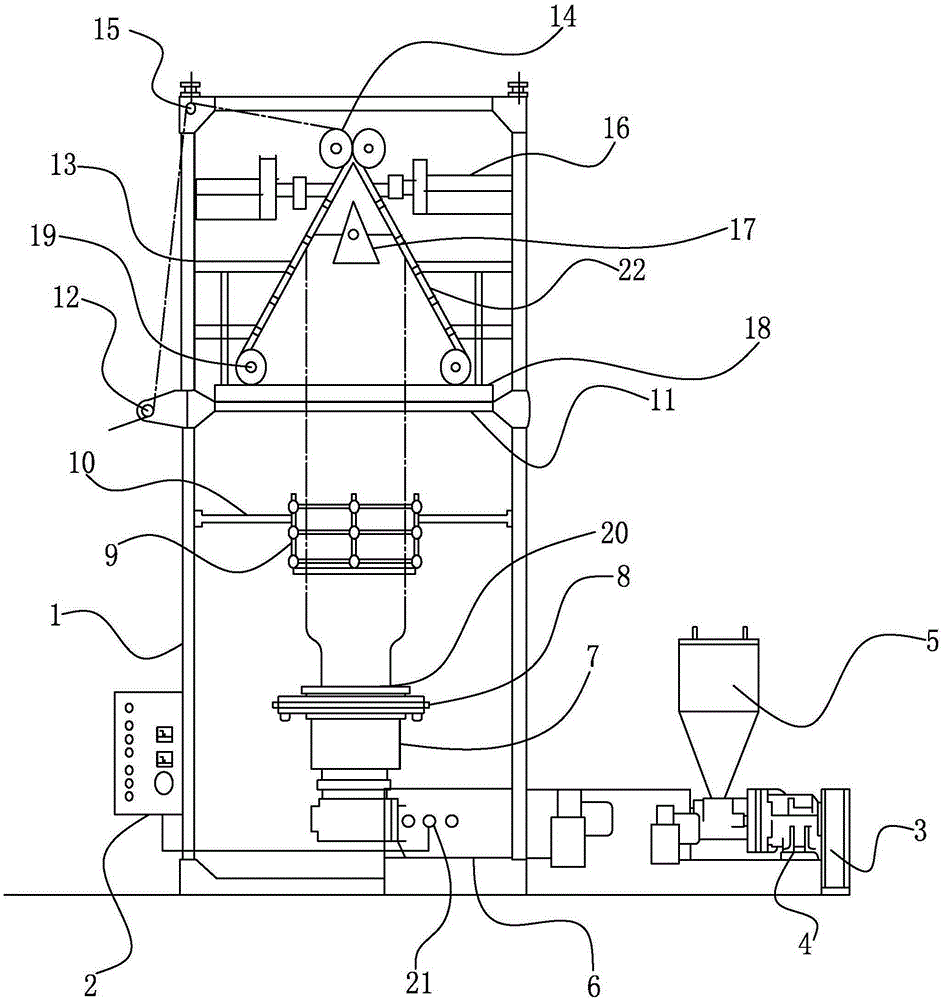

[0018] Example: such as figure 1 Shown: a new type of film blowing machine, including a frame 1, a transmission device, and a control panel 2; the control panel 2 is installed on the frame 1, and the transmission device is connected with a die head 7 at the center of the frame 1; This transmission device comprises the main engine triangular wheel 3, the gearbox 4, the feed hopper 5 and the main engine linkage shaft 6 which are arranged successively from right to left; There is a high-speed air ring 8, and the center of the high-speed air ring 8 is provided with a blowing core 20. By adjusting the blowing core 20 to adjust the center of the plastic bag, it not only ensures the uniform thickness of the plastic bag film, but also facilitates the transmission of the plastic bag film The upper end of the high-speed air ring 8 is equipped with a limit plate 9 of adjustable size, and the limit plate 9 moves up and down by being arranged on the limit plate holder 10 arranged at the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com