Edible film material containing nanocellulose, edible film and preparation method of edible film

A technology of nanocellulose, membrane material, applied in the direction of climate sustainability, sustainable manufacturing/processing, flexible covering, etc., can solve the problems of low mechanical strength, low barrier performance of edible film, etc., to improve health care function , the effect of excellent mechanical properties and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

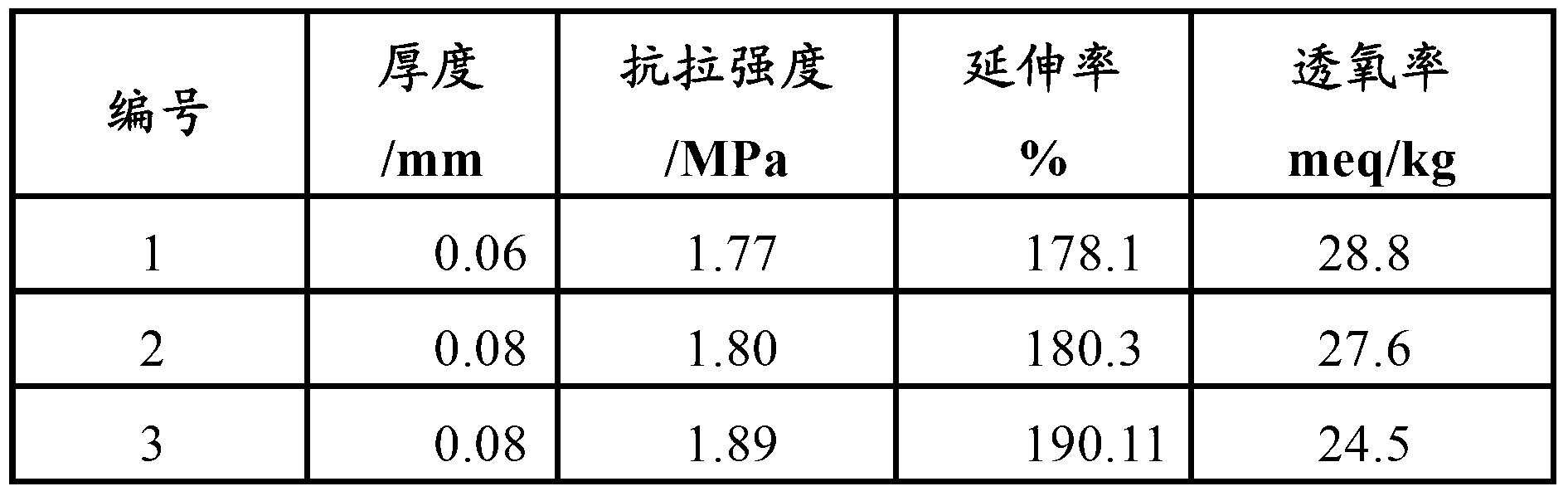

Examples

Embodiment 1

[0050] Step A: Add 10wt% nanocellulose colloid to pure water of the same quality, stir and dilute, and perform high-pressure homogenization at a homogenization pressure of 15 MPa for later use.

[0051] Step B: With 60% ethanol aqueous solution (70 parts by weight) as solvent, 20 parts by weight of nanocellulose colloid obtained in step A, 40 parts by weight of modified starch (wherein, 20 parts by weight of gelatinized starch, 20 parts by weight of esterified starch weight), 6 parts by weight of sodium carboxymethyl cellulose, and 4 parts by weight of gelatin are added to the mixer machine and fully stirred and mixed; then 3 parts by weight of glycerin are slowly added to the mixer while stirring, and the mixture is used ;

[0052] Step C: Apply the mixture of step B on the film forming machine, set the electronic control speed to 0.5m / s, set the temperature to 85°C, turn on the film forming machine, and process for 25 minutes. Remove the film, the film thickness is 0.06mm, ...

Embodiment 2

[0055] Step A: Add 9% nano-cellulose colloid to the same weight portion of pure water, stir and dilute, then carry out high-pressure homogenization, the homogenization pressure is 20 MPa, and set aside.

[0056] Step B: With 68% ethanol aqueous solution (90 parts by weight) as solvent, 30 parts by weight of nanocellulose colloid obtained in step A, 50 parts by weight of modified starch (wherein, 35 parts by weight of gelatinized starch, 15 parts by weight of esterified starch Weight), 10 parts by weight of sodium carboxymethyl cellulose, 5 parts by weight of gelatin are added in the mixer machine and fully stirred and mixed; then 3 parts by weight of glycerin and 2 parts by weight of sorbitol are slowly added to the mixer while stirring In, mix well and set aside;

[0057] Step C: Apply the mixture of step B on the film forming machine, set the electronic control speed to 0.5m / s, set the temperature to 75°C, turn on the film forming machine, and process for 30 minutes. Remove...

Embodiment 3

[0060] Step A: Add 7% nano-cellulose colloid to the same weight portion of pure water, stir and dilute, then carry out high-pressure homogenization, the homogenization pressure is 18 MPa, and set aside.

[0061] Step B: With 60% ethanol aqueous solution (110 parts by weight) as solvent, 35 parts by weight of nanocellulose colloid obtained in step A, 35 parts by weight of modified starch (wherein 25 parts by weight of gelatinized starch, 10 parts by weight of esterified starch weight), 6 parts by weight of gelatin, and 2 parts by weight of pectin are added into the mixer machine and fully stirred and mixed; then 4 parts by weight of glycerin and 3 parts by weight of xylitol are slowly added to the mixer while stirring, and mixed uniform and ready for use;

[0062] Step C: Apply the mixture of step B on the film forming machine, set the electronic control speed to 0.4m / s, set the temperature to 95°C, turn on the film forming machine, and process for 20 minutes. Remove the film,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com