Graphite-nanocellulose-polyvinyl alcohol composite conductive hydrogel and preparation method and application thereof

A technology of nanocellulose and polyvinyl alcohol, which is applied to conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of graphene-nanocellulose-polyvinyl alcohol composite conductive materials that do not have good mechanical properties and electrical conductivity. Gel and other problems, to achieve the effect of strong plasticity, good self-healing function and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

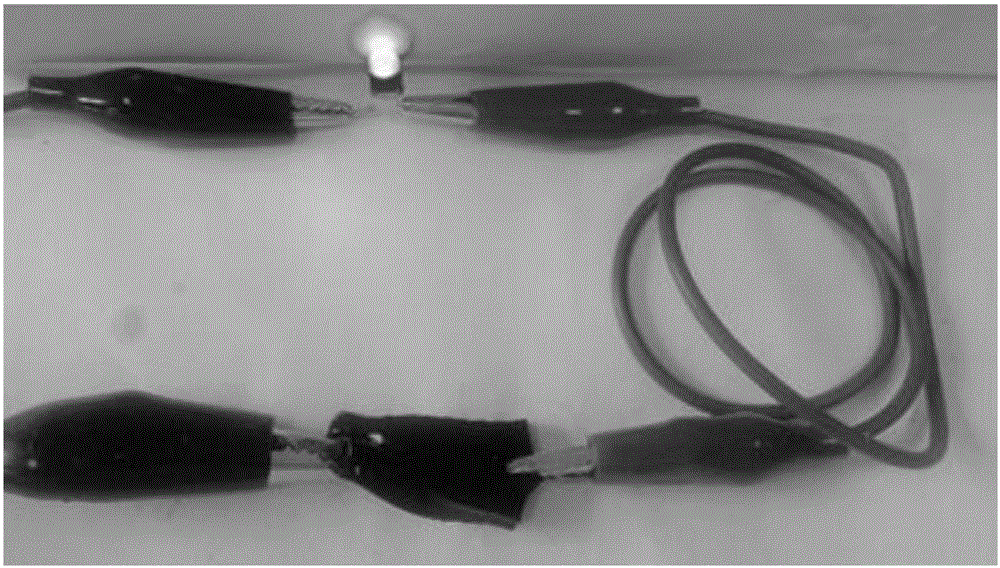

Embodiment 1

[0056] Step 1, the preparation of graphene dispersion liquid and nanocellulose suspension, its concrete method step comprises:

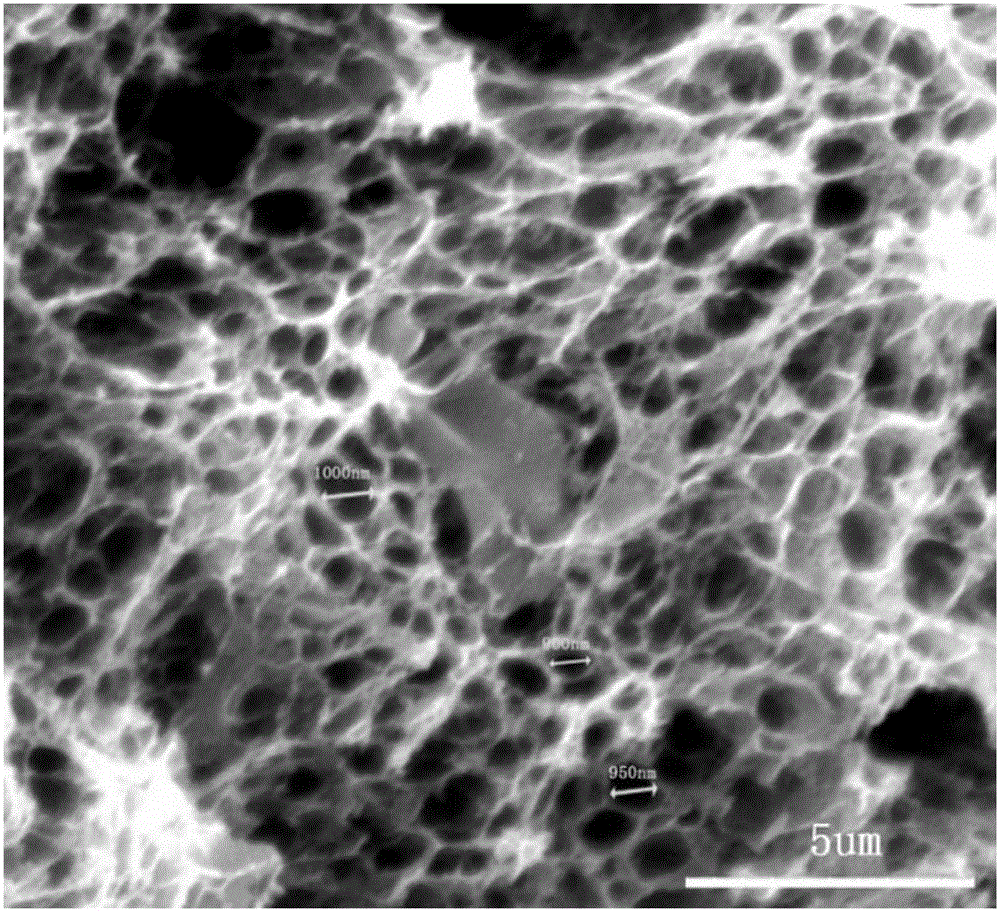

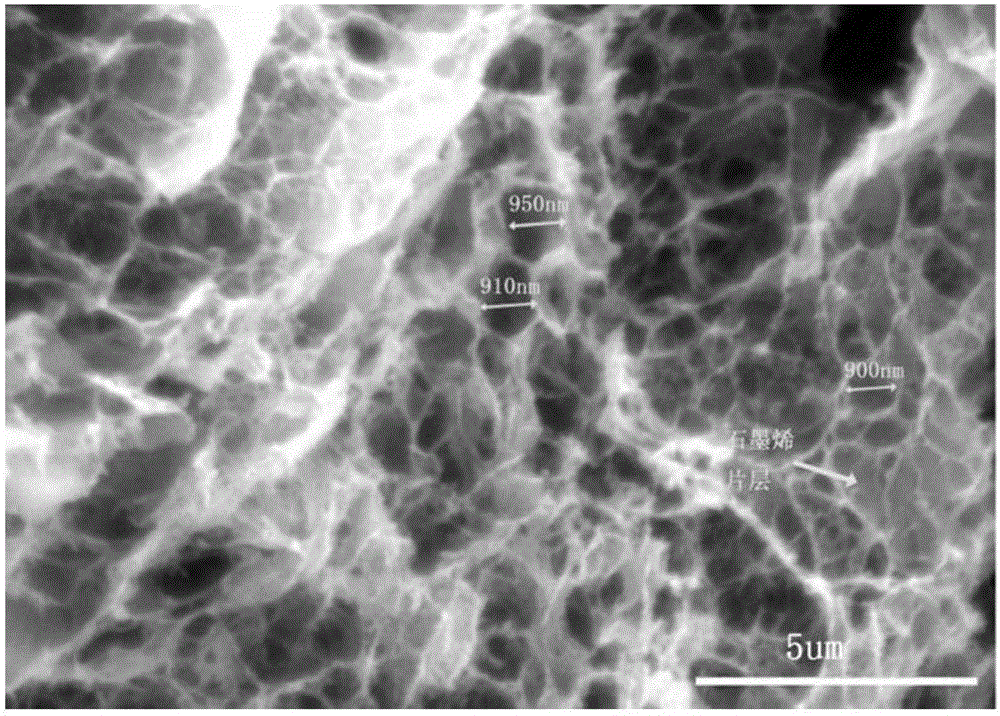

[0057] (1) Weigh 5g of polyvinylpyrrolidone and add it to 500g of absolute ethanol, stir and dissolve (magnetic stirring at 40-50°C until the powder is completely dissolved to form a uniform and transparent solution, the same below), as a graphene dispersant. (2) Add 2.5g of multi-walled graphene, and ultrasonically disperse for 10 minutes at a power of 700w to prepare a graphene dispersion (concentration of about 0.5%). (3) Take 20 g of pulverized absorbent cotton and add it to 400 g of sulfuric acid with a mass fraction of 48%, and carry out acidolysis for 60 minutes under magnetic stirring in a constant temperature water bath at 45°C. (4) Deionized water was added to terminate the acid hydrolysis reaction, and the resulting mixture was rinsed repeatedly with deionized water, and then transferred to a dialysis bag for dialysis for 3 days until the ...

Embodiment 2

[0061] Step 1, the preparation of graphene dispersion liquid and nanocellulose suspension, its concrete method step comprises:

[0062] (1) Weigh 5g of polyvinylpyrrolidone and add it to 500g of absolute ethanol, stir to dissolve, and use it as a graphene dispersant. (2) Add 2.5g of multi-walled graphene, and ultrasonically disperse for 10 minutes at a power of 700w to prepare a graphene dispersion (concentration of about 0.5%). (3) Take 20 g of pulverized absorbent cotton and add it to 400 g of sulfuric acid with a mass fraction of 48%, and carry out acidolysis for 60 minutes under magnetic stirring in a constant temperature water bath at 45°C. (4) Deionized water was added to terminate the acid hydrolysis reaction, and the obtained mixture was repeatedly rinsed with deionized water, then transferred to a dialysis bag and dialyzed in flowing water for 3 days until the pH was neutral. (5) Ultrasonic pulverize the above mixture for 150 minutes at a power of 900w, and then adju...

Embodiment 3

[0066] Step 1, the preparation of graphene dispersion liquid and nanocellulose suspension, its concrete method step comprises:

[0067] (1) Weigh 5g of polyvinylpyrrolidone into 500g of absolute ethanol, stir to dissolve. (2) Add 2.5g of multi-walled graphene, and ultrasonically disperse for 10 minutes at a power of 700w to prepare a graphene dispersion (concentration of about 0.5%). (3) Take 20 g of pulverized absorbent cotton and add it to 400 g of sulfuric acid with a mass fraction of 48%, and carry out acidolysis for 60 minutes under magnetic stirring in a constant temperature water bath at 45°C. (4) Deionized water was added to terminate the acid hydrolysis reaction, and the obtained mixture was repeatedly rinsed with deionized water, then transferred to a dialysis bag and dialyzed in flowing water for 3 days until the pH was neutral. (5) Ultrasonic pulverize the above mixture for 150 minutes at a power of 900w, and then adjust the concentration to 1.0%, thereby obtainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com