Method for preparing nano celluloses through high-pressure homogenizing and low-temperature cooling

A nanocellulose, high-pressure crushing technology, applied in the direction of raw material separation, can solve the problems of affecting stability, material agglomeration, and high material temperature, and achieve the effect of improving dimensional stability and overcoming flocculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

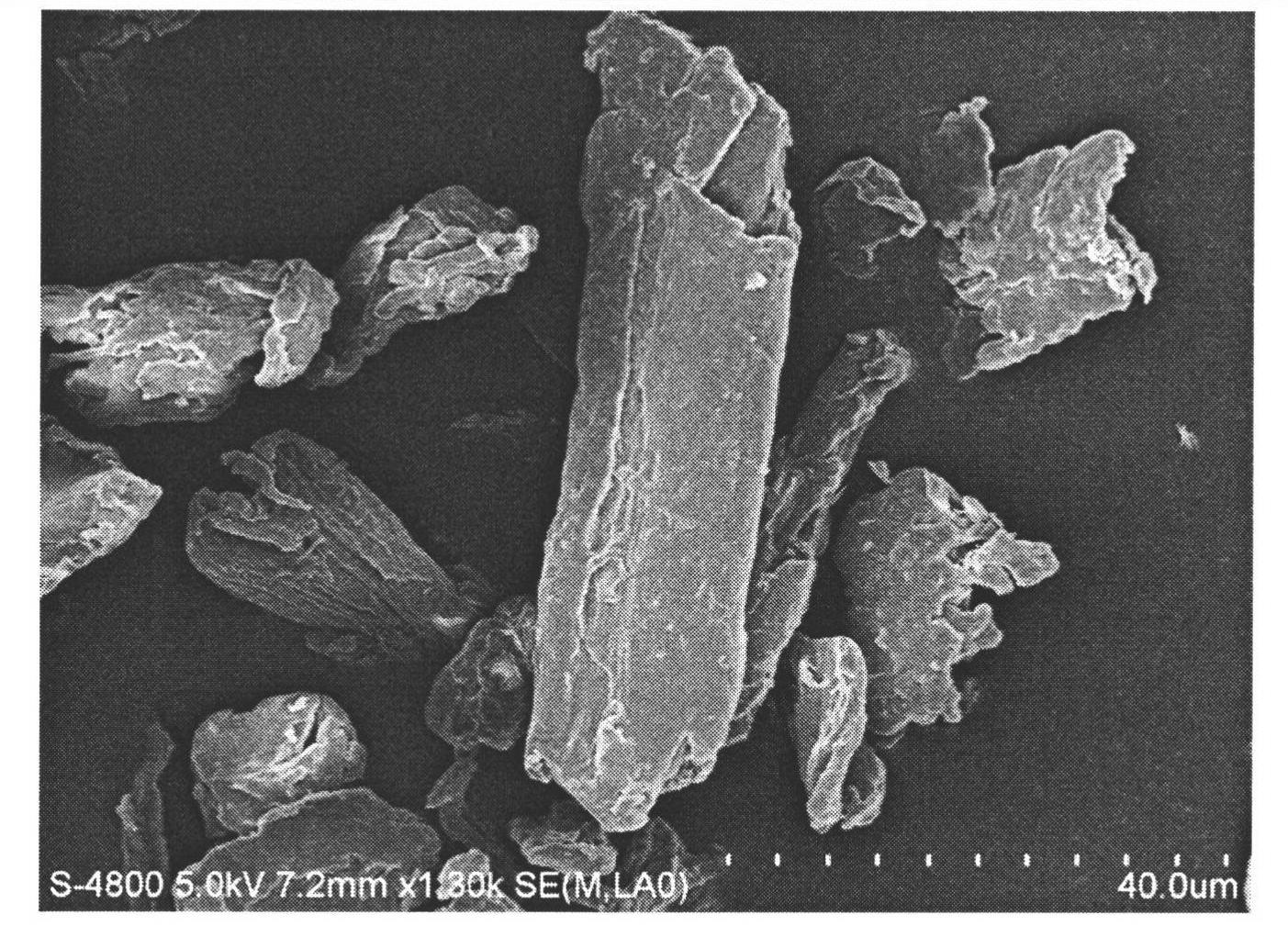

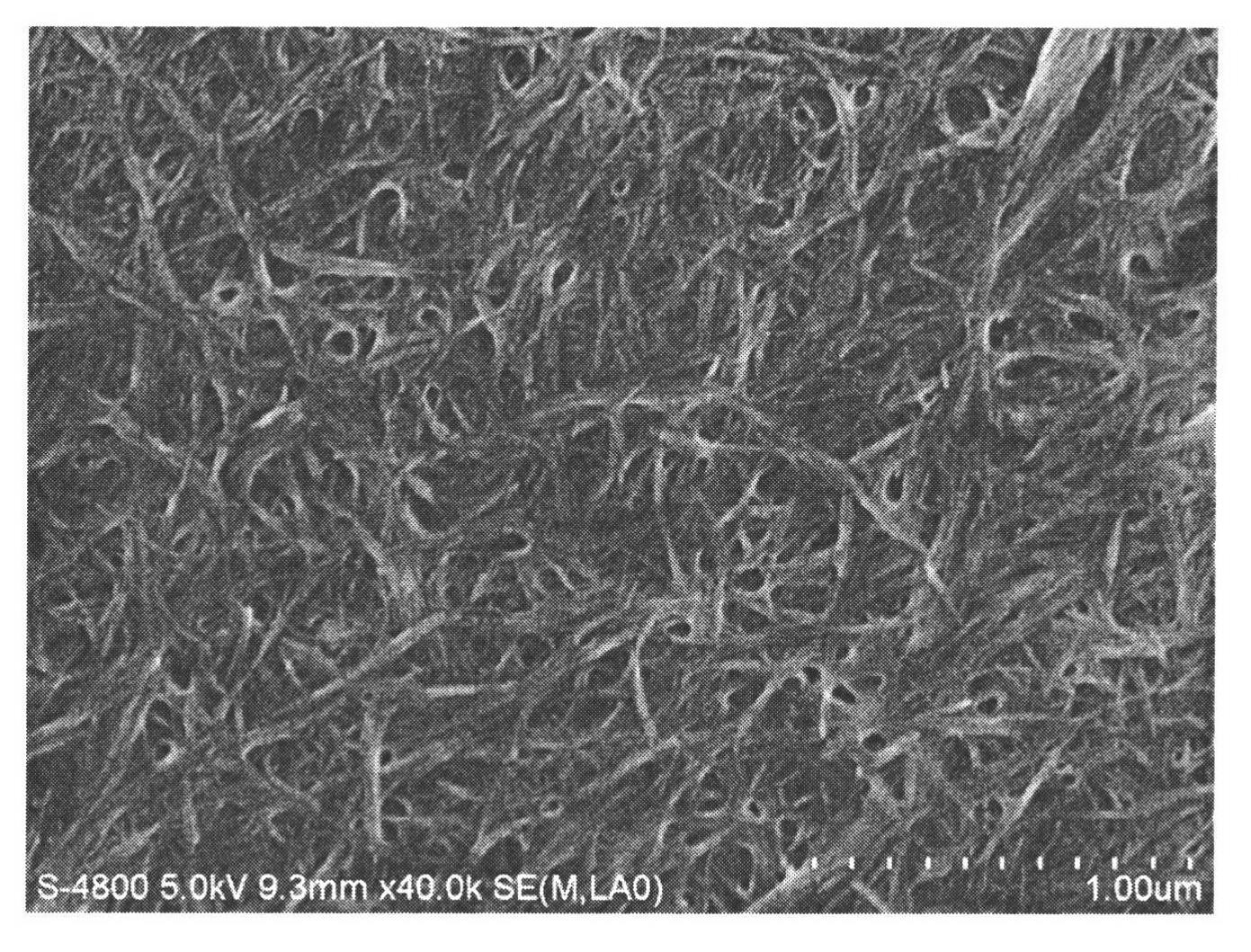

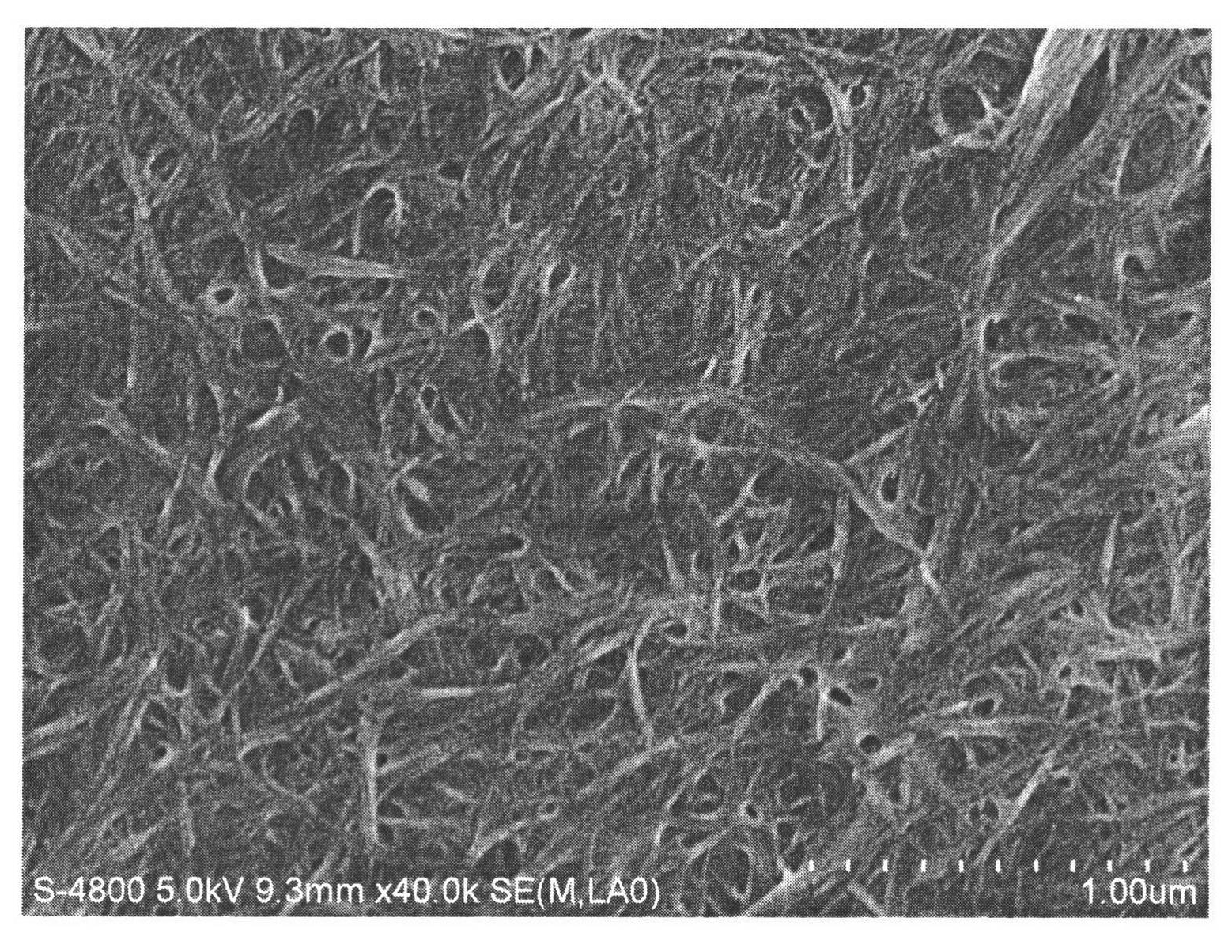

Image

Examples

Embodiment 1

[0011] Example 1, dispersing 2g of fiber raw material in an aqueous sulfuric acid solution with a mass fraction of 10 to 15%, the mass ratio of the fiber raw material to the aqueous sulfuric acid solution is 1:25 to 1:50, and kept at a temperature range of 20 to 60°C. 2h, obtain the aqueous solution of sulfuric acid dispersed with fiber raw materials; add distilled water to the above aqueous solution to dilute, centrifuge, circulate dialysis and filter, add 1% maleic anhydride to the obtained precipitate, and carry out high-pressure crushing with a homogenizer 4 times , the crushing pressure is 1000-1200 bar, low-temperature cooling is carried out during the crushing process to obtain nanocellulose colloid, and then centrifugal separation and freeze-drying are carried out to obtain the product.

Embodiment 2

[0012] Example 2, dispersing 2g of fiber raw material in an aqueous sulfuric acid solution with a mass fraction of 10 to 15%, the mass ratio of the fiber raw material to the aqueous sulfuric acid solution is 1:25 to 1:50, and kept at a temperature range of 20 to 60°C. 4h, obtain the aqueous solution of sulfuric acid dispersed with fiber raw materials; add distilled water to the above-mentioned aqueous solution for dilution, centrifugal separation, and circular dialysis filtration, add 2% maleic anhydride to the obtained precipitate, and perform high-pressure crushing with a homogenizer for 8 times , the crushing pressure is 1000-1200 bar, low-temperature cooling is carried out during the crushing process to obtain nanocellulose colloid, and then centrifugal separation and freeze-drying are carried out to obtain the product.

Embodiment 3

[0013] Example 3, dispersing 2g of fiber raw material in an aqueous sulfuric acid solution with a mass fraction of 15 to 20%, the mass ratio of the fiber raw material to the aqueous sulfuric acid solution is 1:25 to 1:50, and kept at a temperature range of 20 to 60°C. 6h to obtain an aqueous solution of sulfuric acid dispersed with fiber raw materials; add distilled water to the above-mentioned aqueous solution for dilution, centrifugal separation, and circular dialysis filtration; add 1% acetic anhydride to the obtained precipitate, and perform high-pressure crushing with a homogenizer for 16 times. The crushing pressure is 1000-1200 bar, low-temperature cooling is carried out during the crushing process to obtain nano-cellulose colloid, and then centrifugal separation and freeze-drying are carried out to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com